In a big surprise, at least for me, German RepRap showed off a demonstrator 3D printer able to produce very strong silicone prints.

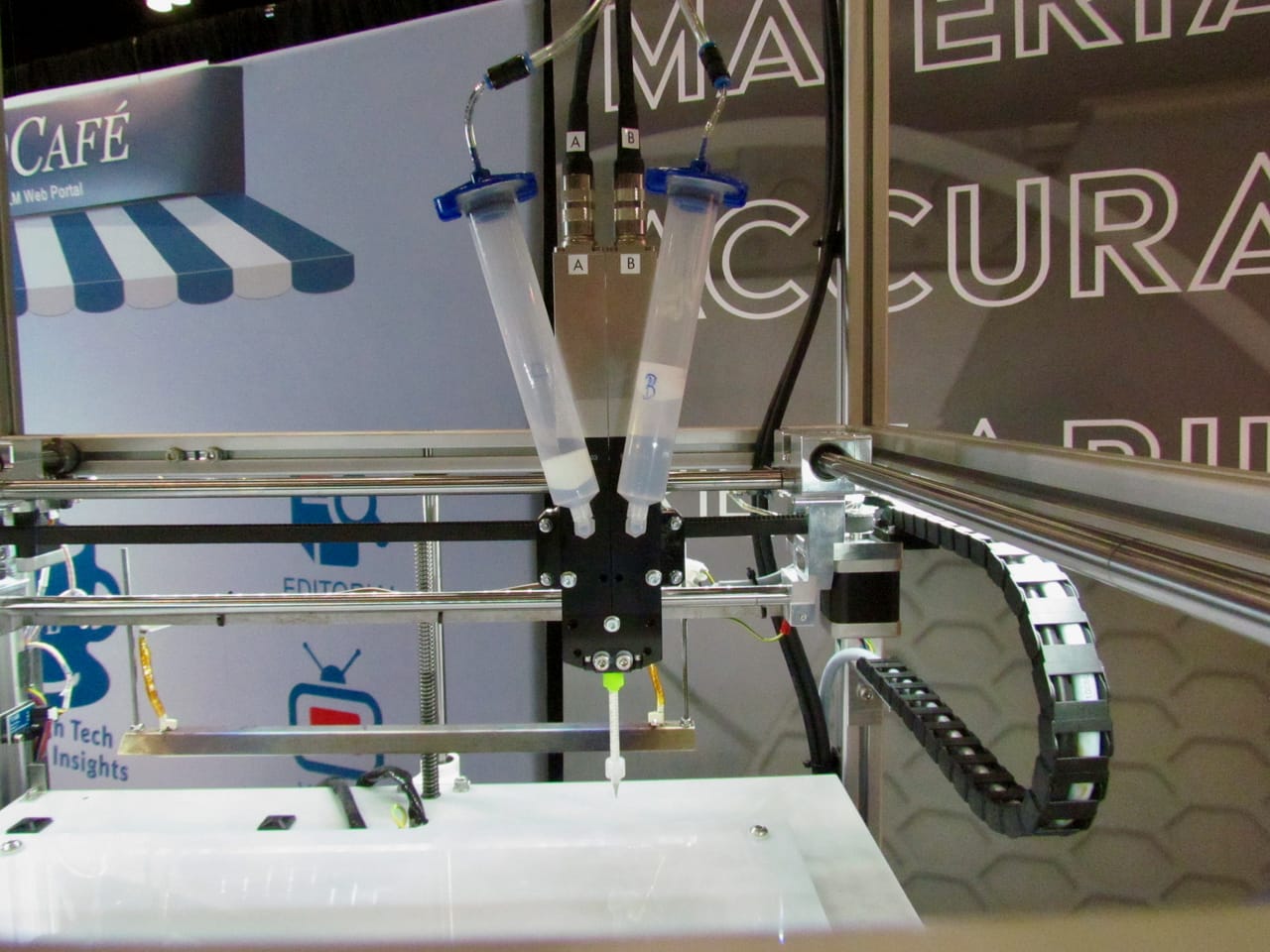

There are few 3D printers able to print in silicone. The sloppy material requires extrusion mechanics far different from typical hard plastic filaments, but some companies have developed syringe-based systems that can do so. But German RepRap’s system is a bit different.

They’ve partnered with chemical giant Dow Chemical, who’s developed a new silicone material specifically for this purpose. It is an “A/B” material, meaning it can be stored continuously in two separate formulations and only becomes the final silicone material when you mix them together.

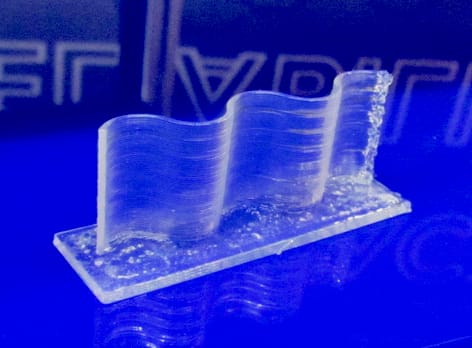

At top you can see German RepRap’s A/B mixing extruder rig, where this takes place. The print surface is the familiar ceramic that is slightly heated. The magic occurs when a heat source is passed over the the freshly deposited A/B mixed layer. Two passes are done to cure the silicone into a very strong structure. Removing prints is as simple as peeling them off with a razor blade.

I’ve personally pulled and twisted some of these silicone prints and found them to be extremely strong regardless of the incredibly thin walls. German RepRap says this chemical/two-pass heating system is superior to the UV approach used by their competitors. They claim it’s strength is “90%” of injected molded silicone. The system is called Liquid Additive Manufacturing, or “LAM”.

And that’s the other thing. As with other 3D printing applications, this system can create geometries that are unachievable with injection molding. In other words, you can make production-quality silicone items never before attempted.

I saw this process on a modified X400 machine, but it’s only for demonstration purposes. The company hopes to migrate the tech into their X400 model to produce a powerful silicone 3D printer, which they may reveal at AMUG.

They’re hoping to develop a food grade certifiable silicone material next, which will open up many possibilities. After that, they are targeting a wide range of polyurethanes.

The machine is definitely of great interest, as it could create new niches in the field.

But there’s one thing that may slow them down. One of their competitors, Picsima, can also 3D print silicone, and it’s very likely they hold some number of patents on their process. I’m wondering if the new German RepRap process somehow steps on any portion of Picsima’s patents. I have no idea, but certainly someone will be looking closely at this.

Meanwhile, stay tuned for some interesting silicone prints in the near future.

Via German RepRap