Graphene. That awesome meta-material that was identified in 1916, imaged in 1948, grown on substrates in the 70’s, and finally manufactured in 2014, has yet to be incorporated into any consumer market applications.

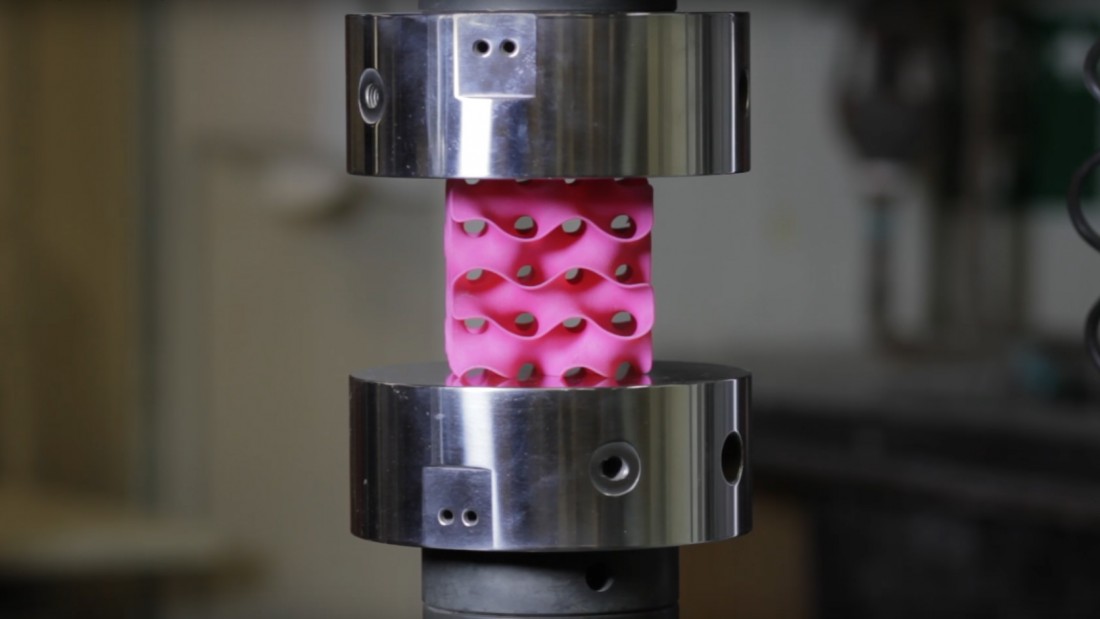

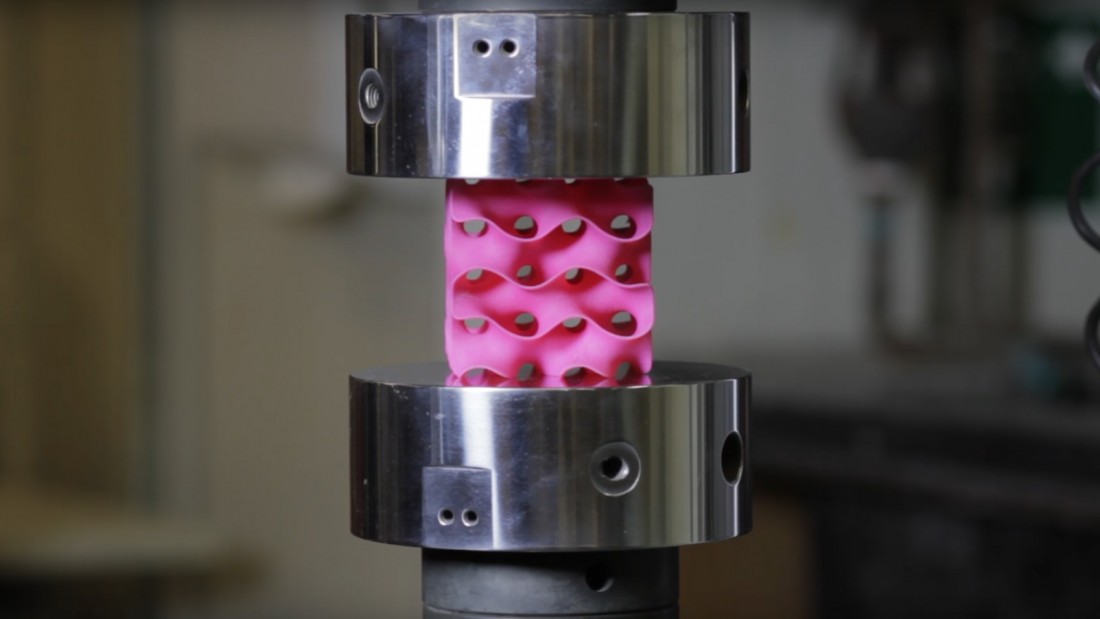

Now, graphene has been developed into a structure stronger than steel and lighter in weight. A team of researchers at MIT found that when they compressed layers of the one-atom thick material and subjected it to intense heat, they could create a new 3-dimensional version of graphene with incredible strength and resiliency.

To put that into perspective, the new sponge-like configuration had only 5% the density of steel but with ten times its strength. This new discovery could have industry-altering effects on spacecraft design, deep ocean exploration and architectural design and significantly affect how designers and engineers consider material usage for design in context of its mechanical structure. The overview video of the research project tells why.

The team’s development is detailed in a research article submitted to Science Advances. As described in the video and shown in the article’s data, the material’s strength doesn’t come from the graphene, but rather its 3-dimensional porous structure, which suggests other materials could be made stronger by assuming the same geometric form. From the abstract:

Recent advances in three-dimensional (3D) graphene assembly have shown how we can make solid porous materials that are lighter than air. It is plausible that these solid materials can be mechanically strong enough for applications under extreme conditions, such as being a substitute for helium in filling up an unpowered flight balloon. However, knowledge of the elastic modulus and strength of the porous graphene assembly as functions of its structure has not been available, preventing evaluation of its feasibility. We combine bottom-up computational modeling with experiments based on 3D-printed models to investigate the mechanics of porous 3D graphene materials, resulting in new designs of carbon materials. Our study reveals that although the 3D graphene assembly has an exceptionally high strength at relatively high density (given the fact that it has a density of 4.6% that of mild steel and is 10 times as strong as mild steel), its mechanical properties decrease with density much faster than those of polymer foams. Our results provide critical densities below which the 3D graphene assembly starts to lose its mechanical advantage over most polymeric cellular materials.

Read the rest at SolidSmack.com