I’m looking at 3D print startup Feetz, which focuses on custom printed footwear for buyers.

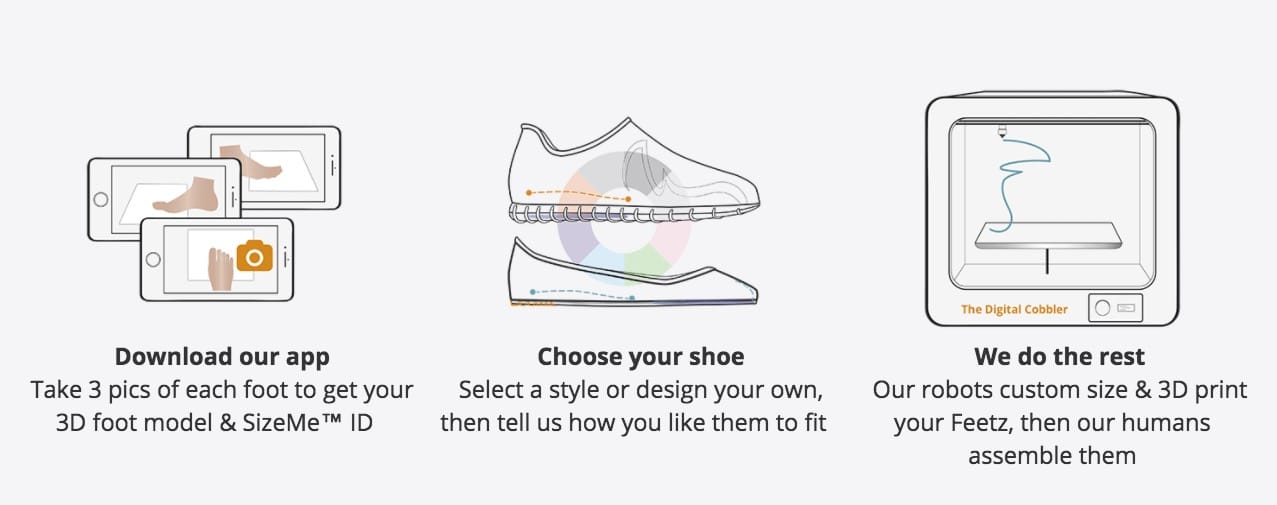

The startup was founded by entrepreneur and former mathematician Lucy Beard, whom we featured last week. Feetz’s business model is straightforward: a customer performs a rudimentary 3D scan of their feet, and submits the data to Feetz. Feetz uses their custom algorithms to generate a specific shoe 3D model in the selected design and at the correct sizing. They then produce the shoes and ship to the customer for payment.

The Feetz system apparently uses “22 dimensions of fit” and is said to be “The Most Advanced Fit In The World”. It may be so.

This seems like a very reasonable way to leverage 3D printing, which is best used for 3D printing custom, one-off items. Mass manufacturing can only produce identical items per manufacturing run, constraining the choice of the customer to only those versions produced.

And then there’s feet. Your feet. The mass manufacturing process we’ve all been exposed to for decades has actually fooled us: if asked what size your feet might be, you would answer with a SINGLE number representing a manufacturing size category.

In fact, your feet are actually different sizes. They might be close enough in size to sort-of fit within a manufacturing size category, but it will not be an optimal fit. You’ve been brainwashed by manufacturing to think your feet are identical, and they are not.

That’s where companies like Feetz come in: they will use your own measurements to produce shoes that theoretically should fit near perfectly. This is a highly desirable feature as most of us use our feet constantly throughout our busy days.

The challenge with such businesses is that it turns out most customers do not have expensive 3D digital foot scanners handy. Who knew?

As a proxy for such equipment, Feetz – and similar operations – have the customer take a few images of their feet from specific angles. Then software interprets the images into a rough 3D model of each foot and the process continues as described above.

What I’m wondering about is this: The process described above is not unique and has been seen several times by this publication. Let’s have a look at how those previous similar companies have fared:

- From 2014 Sols, 3D printed insoles: Appears to be out of business

- From 2015 Footprint Footwear: Website is “under construction”, and probably out of business

- From 2016 MADE: Website domain is for sale

- From 2016 Wiivv, 3D printed insoles: Appears to be operating

The point I’m making here is that this type of business has proven to be very challenging for some and illustrates the difficulty in attempting to bring 3D print technology benefits to the public.

Will Feetz survive and thrive? Possibly, but I believe these businesses need to make the public understand how much better their feet will feel when wearing custom fit shoes. And great fashionable designs would help as well.

Via Feetz