With all the buzz about inexpensive 3D metal printers lately, it’s startling to see one option that doesn’t use a new process.

Pennsylvania-based Xact Metal is a new startup that has developed an inexpensive 3D metal printer that uses the traditional laser-powder bed approach.

The one year-old company is just becoming visible to the public, and was created by several students who felt it might be possible to construct a multi-metal 3D printer.

They ended up creating the XM200, a small volume fully usable 3D metal printer.

The “200” in XM200 refers to the build volume, which is 2000cc’s in a 125 x 125 x 125mm build chamber. It’s not huge, but certainly usable for a great deal of metal prints.

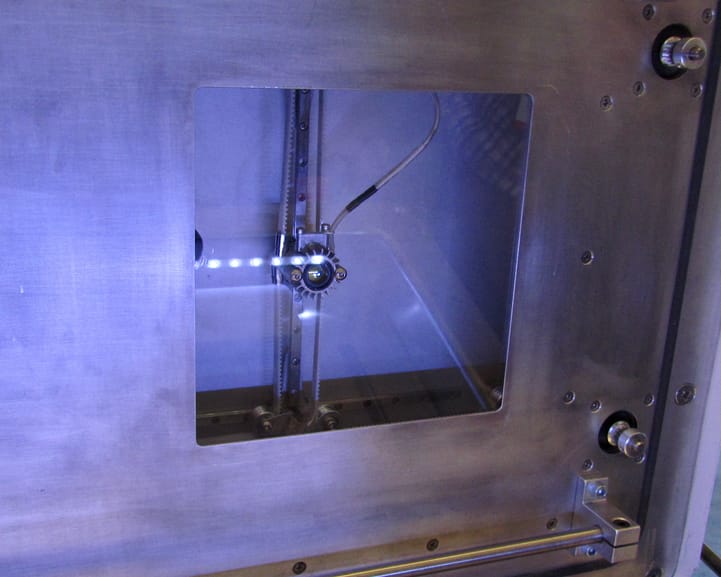

The XM200 uses a 250W fiber laser, similar to what you might find in other far more expensive systems. However, they use it in quite a different way.

Most larger volume 3D metal printers use mirrors to redirect the powerful laser beam to all parts of the powder bed. This has an unfortunate effect on the beam: it’s normal round surface exposure is elongated as it travels to more distant parts of the powder bed.

The XM200 avoids this effect entirely by firing the laser directly at the powder surface. In this image you can see the laser itself, which is attached to a moving platform. It swiftly moves in the X-Y direction over the entire (but small) powder bed surface, crisply solidifying powder without elongation effects.

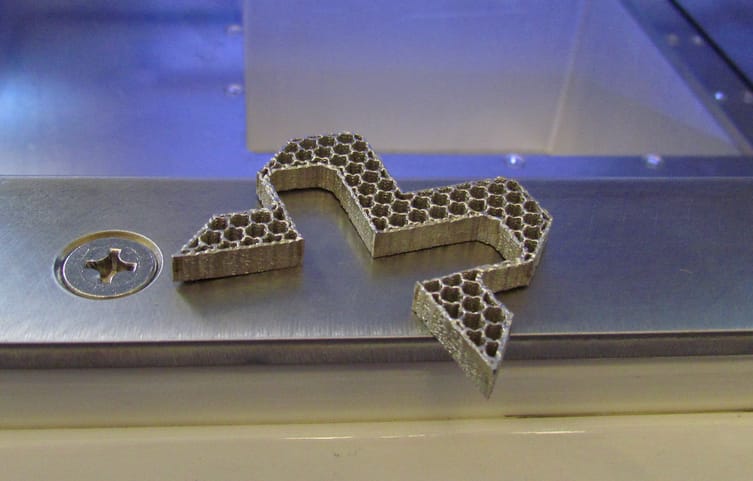

The build chamber is small, shown here. When in operation it is purged of oxygen by filling it with inert argon gas. The powder recoater works by pushing powder from one area to the other, which slowly lowers as the print proceeds. As in other powder-based 3D metal printers, unused powder is reusable, so long as it is sieved and cleaned beforehand.

But the big deal about this machine is its price. For only USD$120,000, you can have a true 3D metal printer, about the same price as the Desktop Metal Studio system.

However, for the Xact Metal XM200 you will need three-phase 220V input power, as well as a number of other machines to extract the prints from metal build plates and finish them with CNC milling equipment.

The XM200 is set to ship this September.

Via Xact Metal