There’s plenty of competition in the 3D printer filament market these days, so it takes a lot to stand out among the crowd. It seems that 3dk.berlin has done so with their new “k-top” product.

The material is described as a “4D” filament by 3dk.berlin, perhaps because the substance changes as you use it in the prescribed manner.

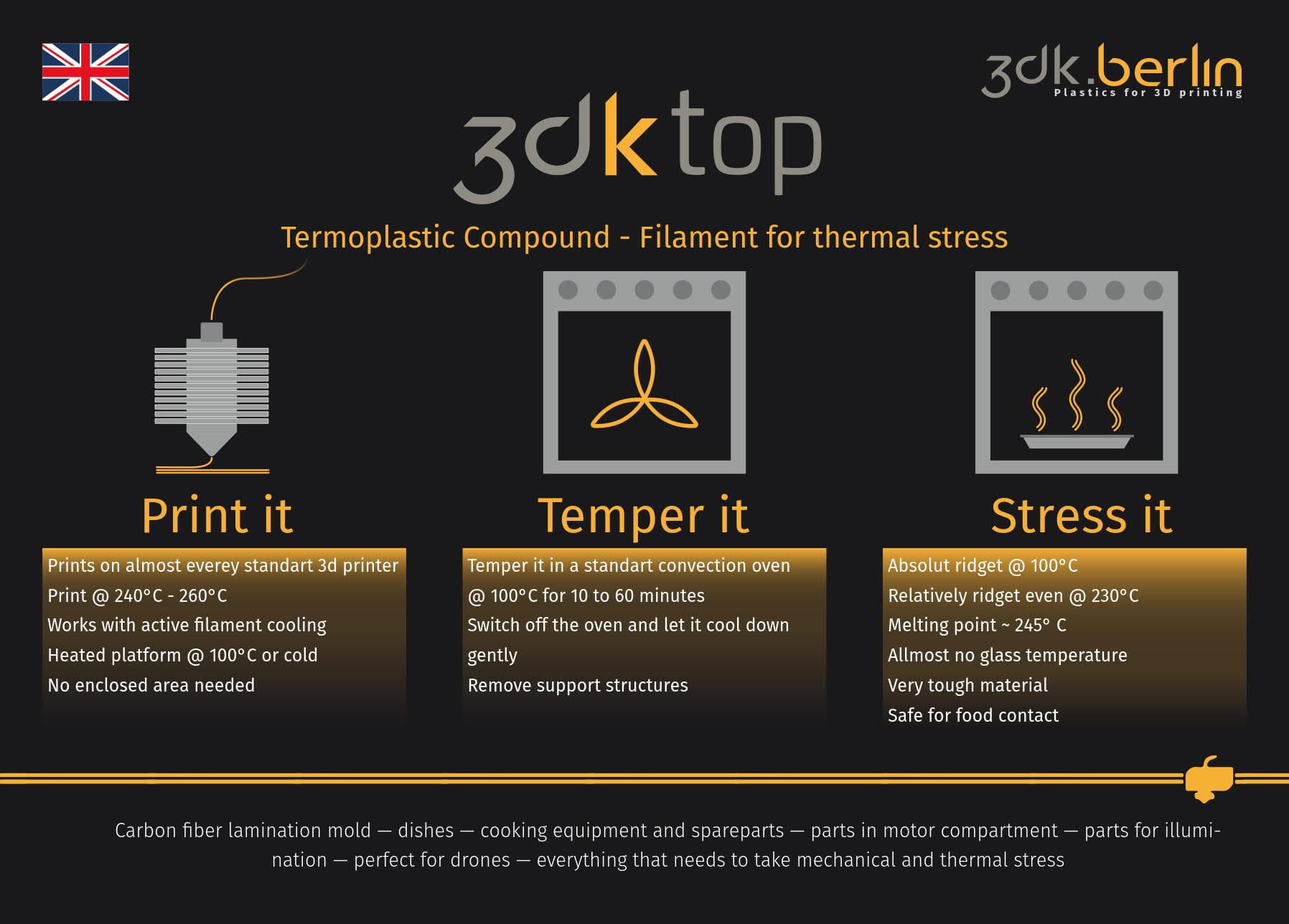

3dktop, as it is known, offers several useful properties, including a strength somewhat greater than ABS and PLA, but also additional heat resistance. 3dktop is “temperature resistant up to 230C”, and requires a 260C hot end to print.

What’s particularly interesting is that you do not require a heated bed or chamber to print this stuff. You can print it on almost any desktop 3D printer:

A heated bed or a heated printing chamber aren´t necessary. 3dktop prints docile, accepts active cooling and owns a great inter-layer adhesion.

But then you must undertake a final step to complete the process, quite unlike any other filament I’ve seen.

As per the chart above, you must temper the printed object in a convection oven at 100C for a period of time proportional to the volume of the print. Why do this? They explain:

The 4th dimension shows itself while crystallizing the material, which triggers the structural change of the material. Thus a thermal resistance of 200 °C (constant load) or 230 °C (peak) is reached.

If crystallization is spared, the print result is extremely impact resistant and can take huge mechanical loads. Temperature resistance is located at 80°C in this case.

So it seems that this material can offer different properties depending on how you temper the printed part.

I’m pumped to see this type of product introduction, because it shows the incredible breadth of possibilities for new 3D printing materials. Up to now, the industry has been relegated to an extraordinarily restricted list of substances with limited properties.

What has it taken for this to happen? It seems to me that the gradual growth of 3D printing has finally attracted the attention of major plastics firms, one of which is Bernhardt Kunststoffverarbeitungs GmbH, the company behind 3dk.berlin. This and other experienced plastics manufacturers have in many cases decades of experience developing the chemistry of unusual materials.

And now that knowledge is being unleashed on the unsuspecting 3D print world.

Via 3dk.berlin