Formlabs announced some highly desirable accessories for their very popular Form 2 desktop 3D printers.

The company has been very successful in development and marketing of their most recent desktop 3D printer, the Form 2. This device uses a photopolymer process in which solidification of liquid resin is done by a laser that swipes across the build plane.

We’ve been using Form 2’s at our lab and found them to be exceptionally easy to use, having been refined through years of experience with their previous product, the Form 1 and Form 1+.

When using the Form 2 I found the machine to be extremely reliable and easy to use, as the interface is simplified. If you carefully observe the Form 2’s processing sequence, you will see it take a number of steps that no doubt increase the print reliability. They seem to have optimized the speeds and feeds of this machine.

But while the Form 2 itself works quite well, post-printing is a bit different. There are two stages to post-processing, one mandatory and one optional: cleaning off excess liquid resin and final curing.

The Form 2 prints are literally dripping with uncured liquid resin as they emerge from the resin tank when the print job completes. This resin is not something you want to be playing with, as some resins can be toxic.

To remove the resin, you must bath the wet print in a tub of isopropyl alcohol, which dissolves the resin. Formlabs includes a simple two-tank system for this. Both tanks are filled with IPA, but one is considered the “dirty” tank. It initially receives the wet print and thus the majority of the colored resin dissolves into that tank. That’s why it’s called the “dirty” tank.

The second tank is used for a final cleaning that should leave the part completely free of resin.

After cleaning, some may wish to perform additional UV curing on the photopolymer print to ensure it is as hard as possible. Some Form 2 operators actually construct a “curing station”, which is basically a box with a UV light inside. Prints can be dropped in the curing station for a period of time for final curing. Formlabs even promotes a method of making your own curing station.

But there are issues with the cleaning process. It is a manual process and can be a bit sloppy. You should definitely be using rubber gloves as you don’t want your skin exposed to the IPA or residual resin. It’s also tricky to properly perform the standard ten minute IPA dip if your object is larger than the level of IPA in your tank.

If so, you need to slosh the object around by hand or do two dips, flipping the print over each time.

The problem with post-print curing is that most people don’t bother doing it. And that can result in less than optimal prints in some cases.

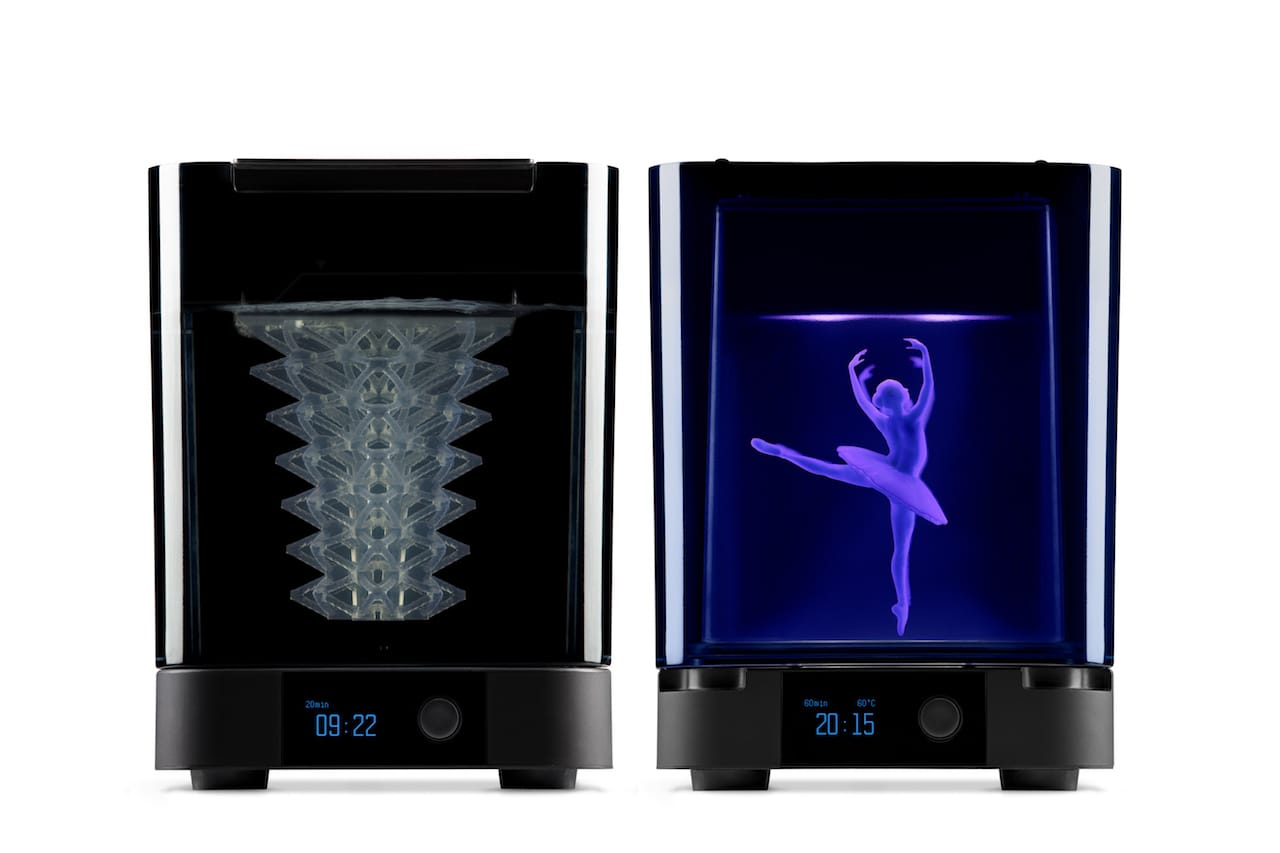

Now Formlabs is solving both of these problems by introducing two new accessories. One is the Form Wash, which is a standalone unit that automatically washes prints perfectly. It works like a dishwasher: you set the time and it agitates IPA through and around the print completely. A motor raises a basket containing the print up out of the IPA when done. If you leave the print for a bit of time, the IPA evaporates and you have a print that’s completely dry. No IPA touch exposure occurs.

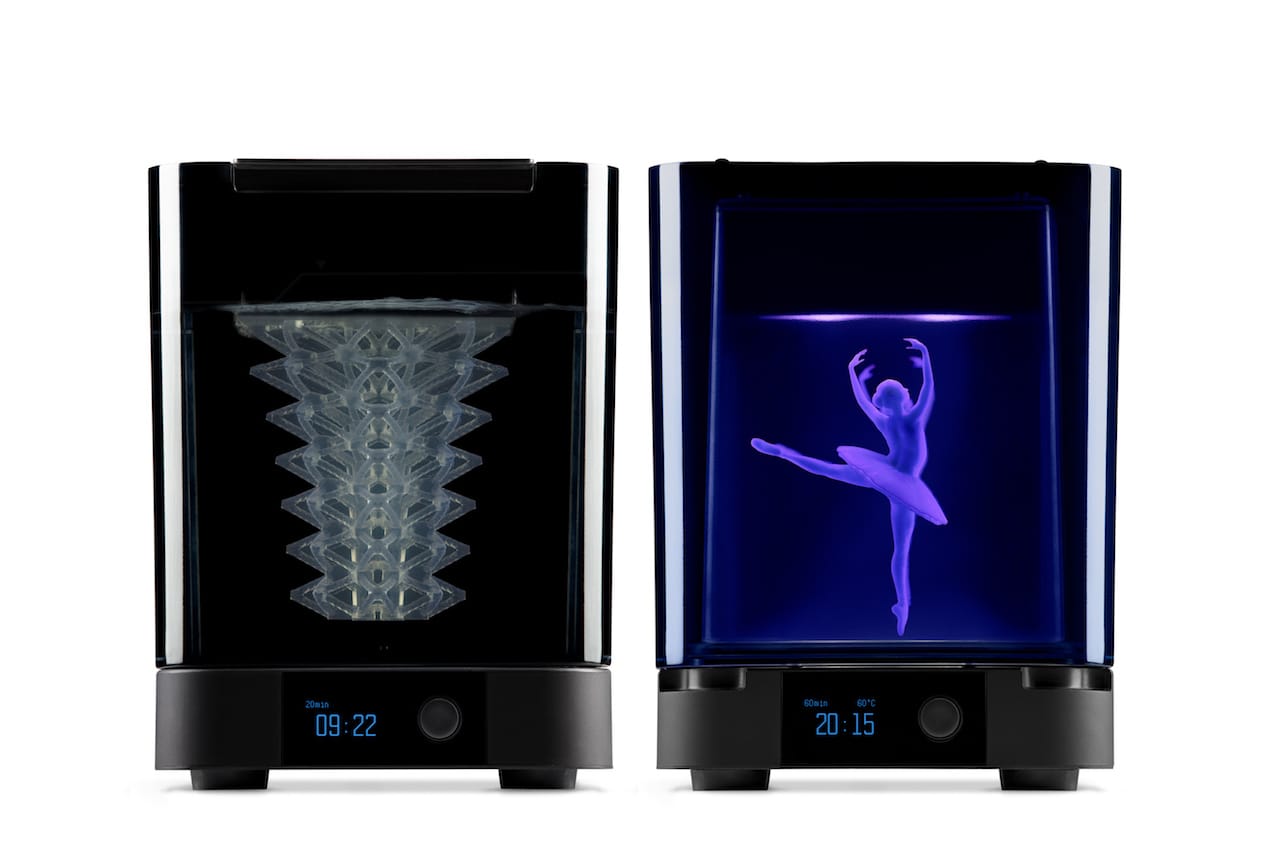

The second accessory is the Form Cure, a standalone UV curing station. It’s an enclosed chamber that includes not only UV illumination, but also heating controls. The Form Cure goes through a timed sequence that should perform a final cure on your print in the optimum manner.

The Form Wash is to be priced at USD$499, while the Form Cure goes for USD$699.

If you have a Form 2 and find yourself doing a great deal of 3D printing, you might consider adding one or both of these devices to simplify your workflow and optimize your prints.

Via Formlabs