The last time we heard of Impossible Objects, they were receiving funding in 2014. Now we’ve seen their 3D printer in person.

The Illinois-based company produces a 3D printer that employs a rather unusual sheet-based process that involves composite materials.

Here’s how their 3D printing process works:

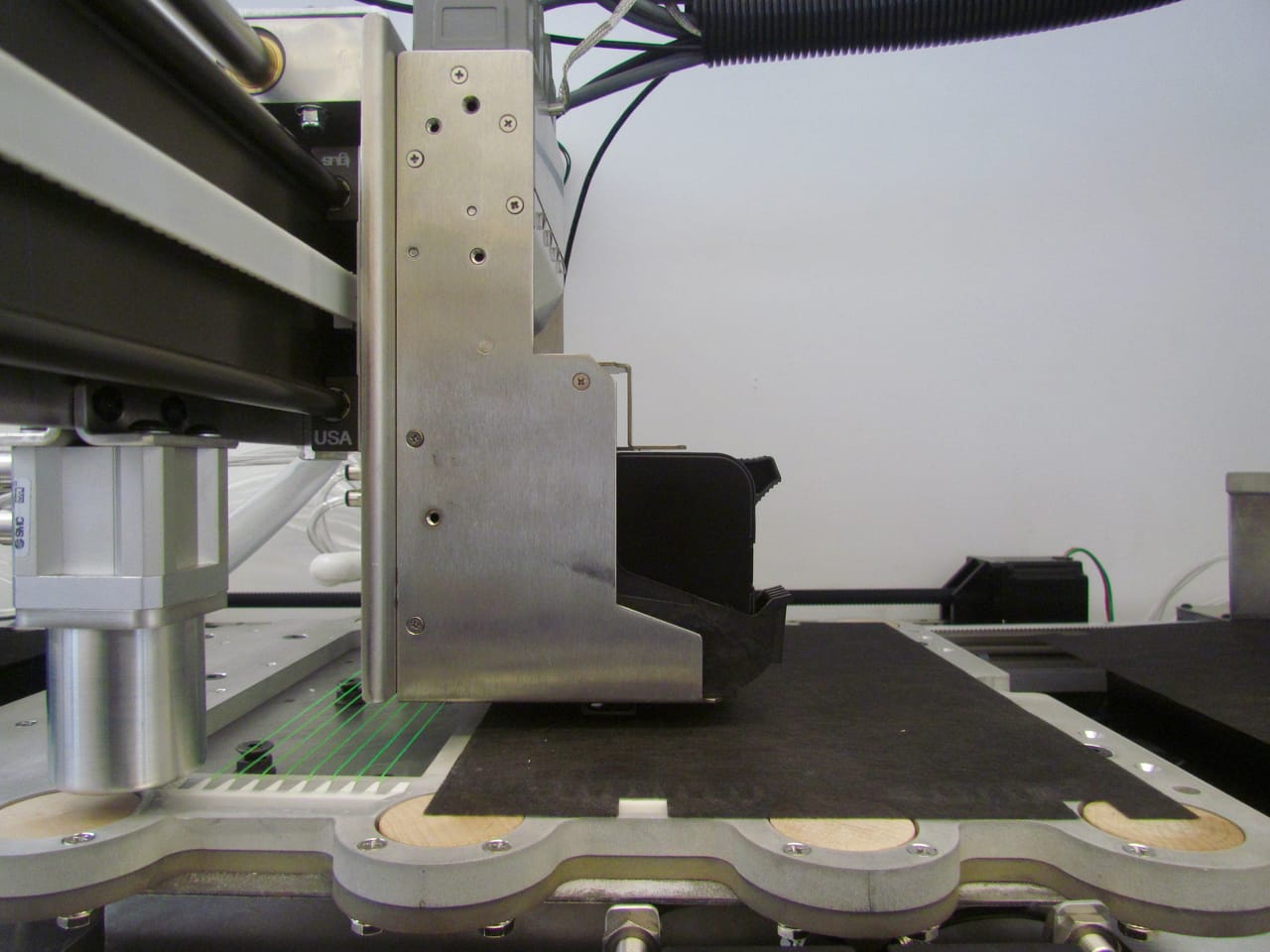

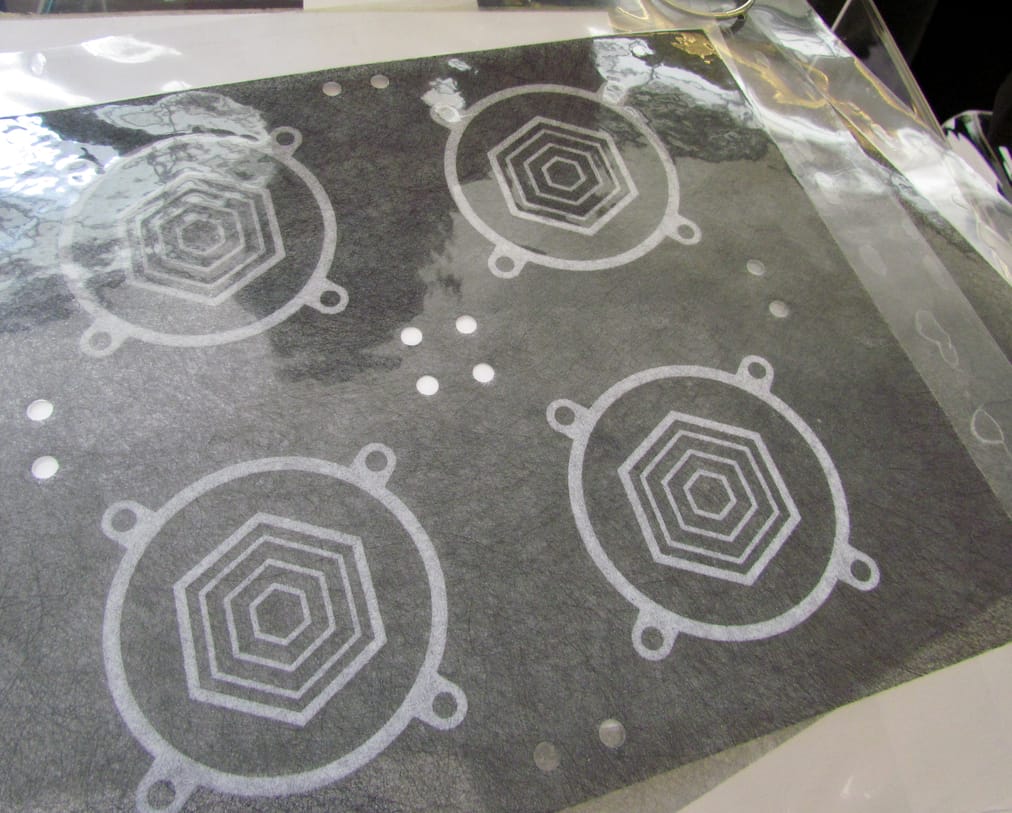

- A standard sheet of, say, carbon fiber material is laid down in the build chamber

- A high-resolution inkjet system selectively drops a special aqueous solution (mostly water) on the sheet

- The entire sheet is swiftly covered in a powder; some powder sticks because of the fluid

- A second sheet is placed on top of the first sheet

- Registration holes are cut into the sheet

- This repeats, layer by layer, sheet by sheet, until the object is complete

- The entire stack, with a shaft through the registration holes is removed

- The stack of sheets, still bound by the registration holes, is placed in a powerful heat press

- The heat press bakes the carbon fiber sheets together in the same manner as is done in non-3D printing applications

- The baked stack is removed from the heat press and excess, non-adhering pieces are cut off, yielding the final object

There are advantages and disadvantages to this approach.

The good news is that you can build incredibly strong parts. The carbon fiber sheets, for example, can include very long strands, as opposed to the chopped-up fibers found in extruded carbon fiber filament used in other machines. Another advantage is that you can use industry-standard composite sheets at good prices available almost anywhere. Nylon, PEEK and other materials are possible.

The disadvantage is that it seems that there are some constraints to the possible geometries available to this process. I can imagine some complex shapes that would prevent the removal of excess sheet material, for example. You could not easily 3D print a nozzle with tiny embedded air conduits.

However, for many parts this could be an excellent way to build them in very strong and light materials.

The company has been working on the device since 2011, and is now ready to launch. We’re told the price of the system is in the USD$150-200K range, depending on options.