We’ve just returned from Pittsburgh, where we spent most of the week attending the annual Rapid conference and trade show.

The event is held annually in the USA, where vendors of all things 3D exhibit and discuss their technologies and capabilities. Originally focused on Rapid Prototyping, the event now largely revolves around 3D printing and related technologies – which just happen to be used today for both rapid prototyping and manufacturing.

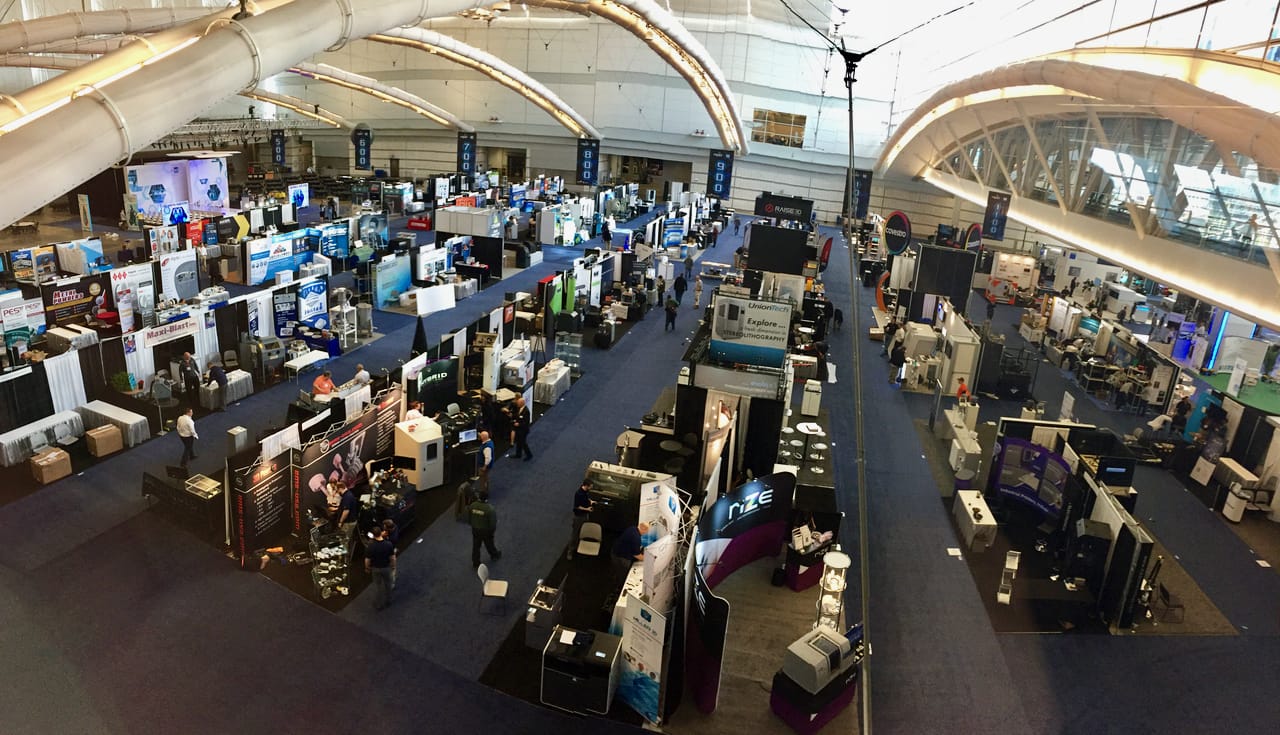

Rapid is one of a scant few large-scale 3D printing events held worldwide, as this event held apparently 330 vendors and something like 20,000 attendees. The only larger 3D print-dedicated event these days seems to be FormNext in Germany, where similar numbers of vendors and attendees participate.

Thus Rapid is an excellent place to check out the current state of affairs in the 3D printing industry.

What did we see?

Lots, actually. We have material for many dozens of stories that will emerge over the next few weeks as we consider what we found and write up our comments. But there were some clear trends evident when looking at numerous vendor offerings. Some themes emerged:

Low cost, unusual 3D metal printing options: For years there have been rather pricey traditional 3D metal printing options available from a small set of vendors. Now there seems to be not one, not two but MANY low cost 3D metal printing options available from startups utilizing innovative 3D printing processes not previously seen. This could result in a significant shakeup of the existing 3D metal printing market.

Low cost, high temperature plastic 3D printers: We saw this at FormNext as well, but there are again large numbers of smaller companies marketing high temp 3D printers capable of 3D printing unusual materials such as ULTEM, PEEK and other exotic materials. They’re addressing the demand from engineers who really need to 3D print in particular materials.

Non 3D print companies looking for an angle to enter the industry: Several long-time CNC companies have introduced 3D metal printers, some even with CNC hybrid configurations, and others of extreme size. There are also multiple companies with sensor, heating or other technologies far more advanced than currently used in typical 3D printers, and they hope to have printer manufacturers incorporate them.

Smaller companies struggling to gain attention: As always there were numerous 3D printing startups, most of which had interesting twists on the technology and process. While all appeared to have a range of experience and skills suitable for the job, at least one we visited had little idea of what they were attempting to do. It’s extraordinarily difficult for these startup companies to attract media attention given the avalanche of press releases from the big guys. And half a day of Stratasys announcements didn’t help them any.

Material suppliers abound: I’m sure the seemingly countless materials providers offer some value proposition, but it’s extremely difficult to stand out among the many competitors if you are selling what is essentially a commodity product, like powdered metal or standard plastics. But even so, it’s fascinating to see how some companies overcome this issue.

It’s big: years ago 3D print market activity was extremely limited, but now we see major conferences with literally hundreds of capable vendors spending vast sums to access rapidly growing markets for this technology. It’s a massive industry at this point, with competition driving innovation every which way.