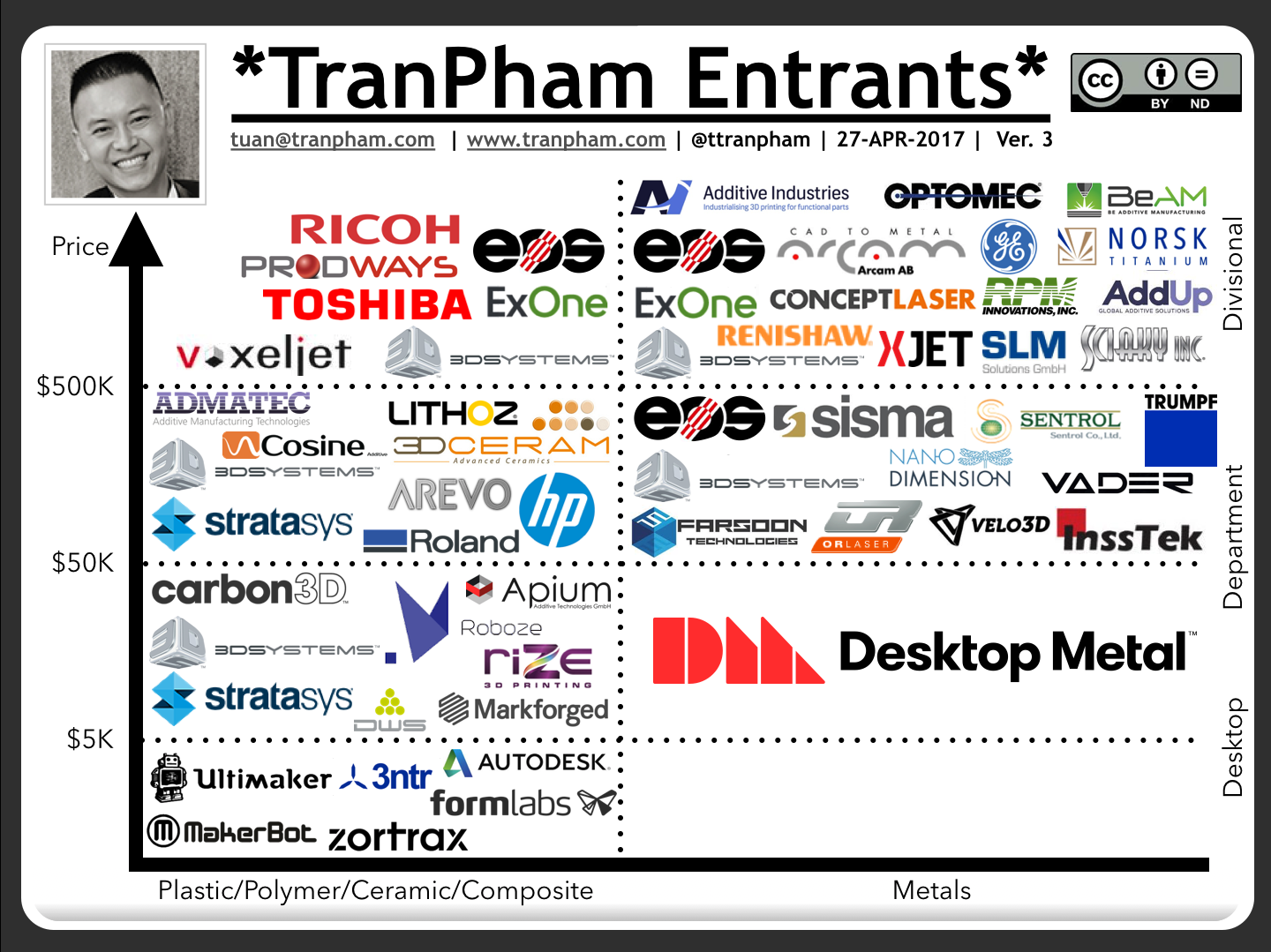

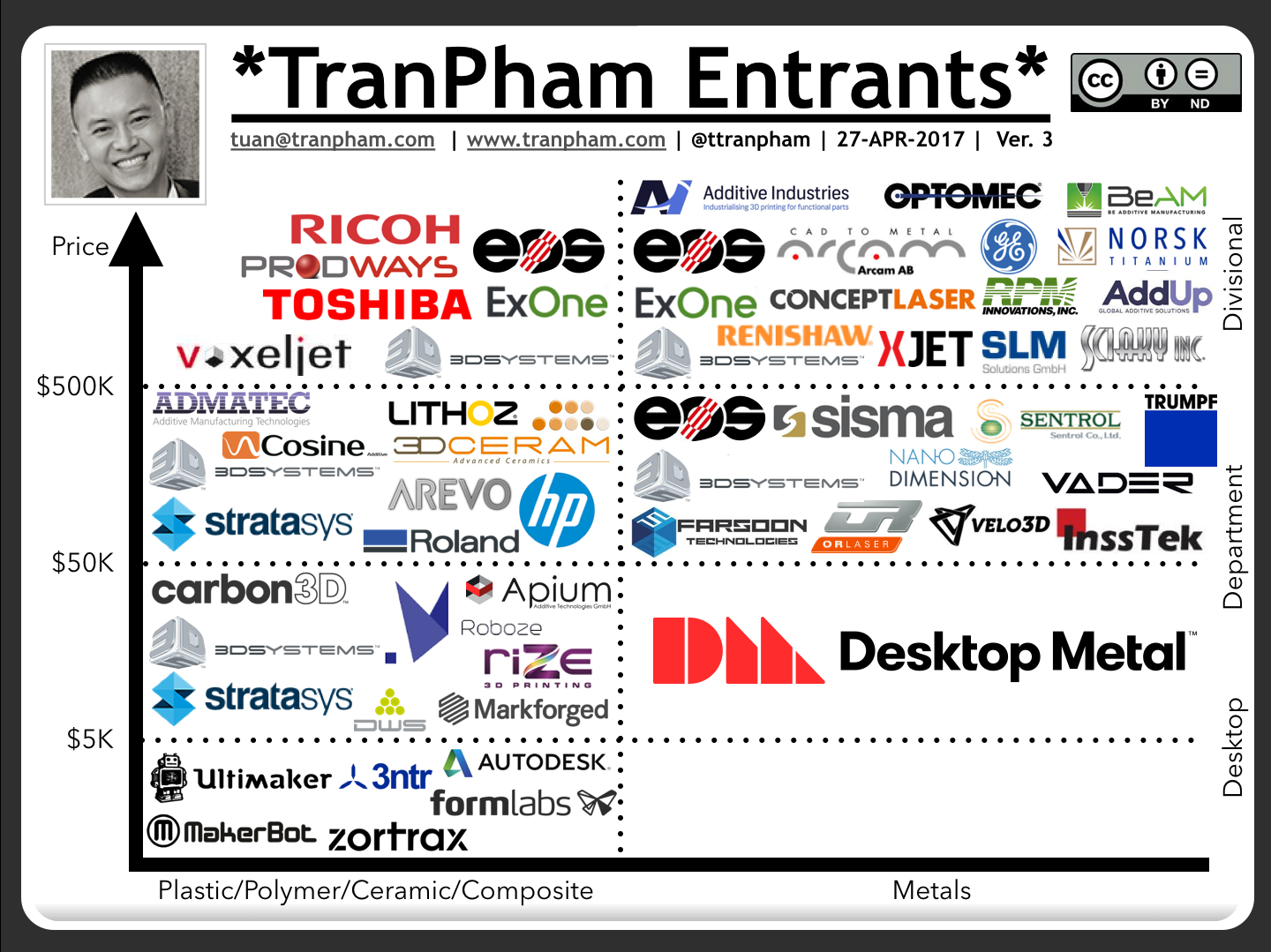

Tuan Tranpham has posted a very telling chart showing where many current 3D printer offerings lay on a financial scale.

Tranpham, a long time friend of Fabbaloo and who currently works for Desktop Metal, a new 3D metal printing startup, regularly produces fascinating analyses of the 3D printing industry. He also appears in the top left corner of the chart above.

In this chart, Tranpham has plotted two columns of 3D printer manufacturer options: plastic on the left and metal options on the right. Of course, there are many more plastic options than could possibly fit, but as you can see there is a complete spectrum of equipment from the lowest desktop equipment to very high end machines suitable for massive production purposes.

On the metal side of the chart, things are a bit different. There is a large clump of vendors at the top end, which in Tranpham’s estimation is over USD$500K in acquisition cost.

Metal 3D printers are expensive! One of the reasons they are so pricey is the use of dangerous metal powder, which must be completely isolated from the surrounding environment as it is often toxic and sometimes even explosive.

These machines must fuse the explosive powder in non-oxygenated build chambers, otherwise catastrophic results may occur. To build air-sealed chambers with precision temperature controls is not cheap.

Extreme heat is required to melt metal and engineering that into a 3D metal printer is similarly expensive.

As a result we see the large number of expensive 3D metal printing systems at the top of the chart.

However, Desktop Metal’s technological approach has eliminated the need for metal powder in their Studio system and prints without the need for extreme heat. This removes the need for a great deal of components in their printer design, and consequently lowers the cost.

I’d make a couple of corrections to the chart, however. One missing element to Desktop Metal’s cost here is the need for a separate furnace system to sinter the green part that comes from the sub-USD$50K printer. That would add to the cost a bit and put in the bottom of the next category up.

Another change might be to add Ability 3D to the lower empty cell. This company is attempting to build a desktop 3D metal printer based on MIG welding gear for only USD$3,000. They’re still developing their product, so this may be the reason Tranpham did not include them. Their recent Kickstarter to raise funds for the development fell drastically short of its goal, so we don’t know how they will proceed forward.

The point I’d like to make is that empty cell at the bottom right on Tranpham’s chart: it’s empty.

Let’s fill it.

Via LinkedIn