A Los Angeles-based company is working a new 3D metal printing process that could prove popular.

3DEO is a new startup that has developed their own patent-pending 3D metal printing process. Like many 3D metal printing processes, 3DEO starts with metal powder.

However, it’s not the same type of metal powder required by other 3D metal printing processes. Those processes require very fine particles because the resolution of the final object is a function of the particle size: the laser fuses the particles together.

But 3DEO’s process is quite different. First, they use a standard industrial metal injection molding powder that is commonly available at low cost. For reference, a fine metal powder suitable for 3D printing might cost as much as USD$500/kg, these commonly available powders instead can cost as little as USD$10/kg, a very substantial saving.

3DEO’s green parts are produced by a special spray head that selectively drops binder onto a bed of this inexpensive powder. They say it’s not an inkjet process, and is the key element they’ve patented.

After repeated applications of powder layers and selective binder deposition, you have a green part. This can be fired later in a furnace to remove the binder and leave, according to 3DEO, a part that’s “90% dense”.

They also say that the strength of the part is isotropic, as layers are bound in the same way in each axis. This is an important capability, as many 3D printers cannot produce parts of this strength.

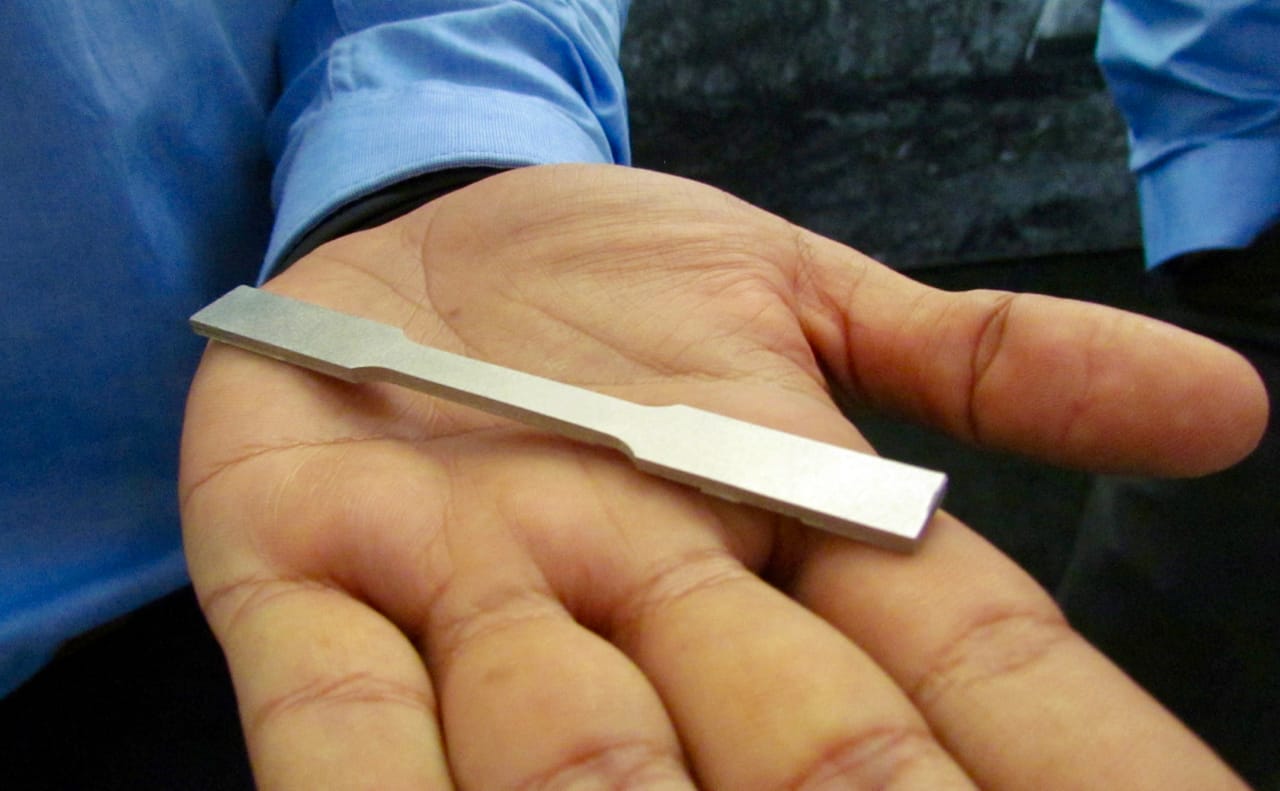

But wait, you ask, how do they achieve the resolution of the part if they are not using fine powder? That’s where the second part of their process comes in: they use a CNC mill to cut away excess material, leaving a smooth surface. The surface finish is as good as you can get with a CNC machine, because it IS DONE with a CNC machine.

We’re told the CNC element works in three dimensions, making many geometries possible. It also can include a tool changer, making it possible to speed up CNC finishing substantially as larger cuts can be made faster, while smaller CNC bits can do the fine detail.

Their machine can 3D print metal objects using this process up to 200 x 200 x 200mm size, and surface finish is excellent. Apparently they also offer a variety of plating solutions to post process printed parts.

So far, the company has opened a 13,000sf facility in Los Angeles, where they have no less than three machines online. They say they are “open for business”.

I get the impression they are operating as a 3D print service for the moment, but it is possible they may offer the machine as a product in the future.

Via 3DEO