If announcing an entirely new 3D printer today, Formlabs also announced a fascinating robotic system that could transform the company’s market.

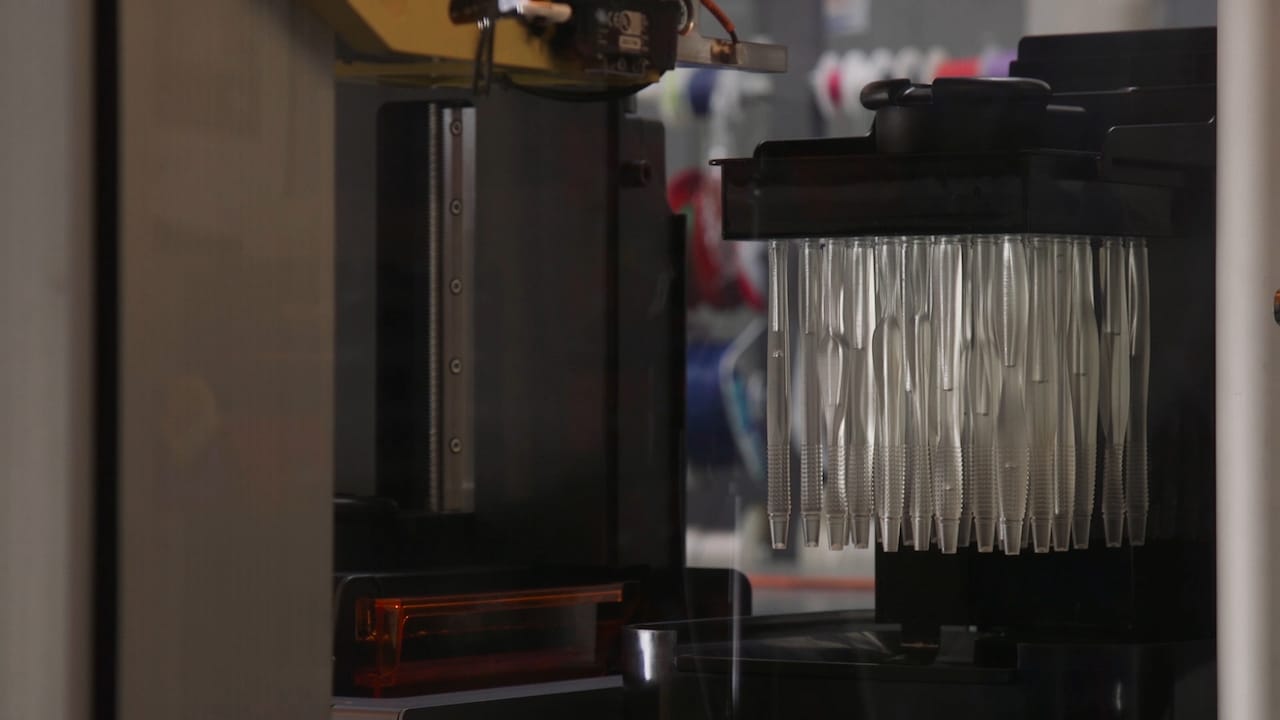

The new product is the “Form Cell”, a robotic environment that provides production capability using standard Form 2 desktop 3D printers.

Yes, it’s a kind of array system, similar to that seen from other vendors, but the Form Cell is not simply a pile of 3D printers. It is also capable of production automation, something I’ve seen only twice before from other vendors – and then only in prototype form.

The system includes five major subsystems:

- A collection of Form 2 desktop 3D printers, which appear to be no different from those you can purchase separately

- The recently announced Form Wash and Form Cure, separate post-print devices for removing resin and finalizing solidification by UV exposure respectively

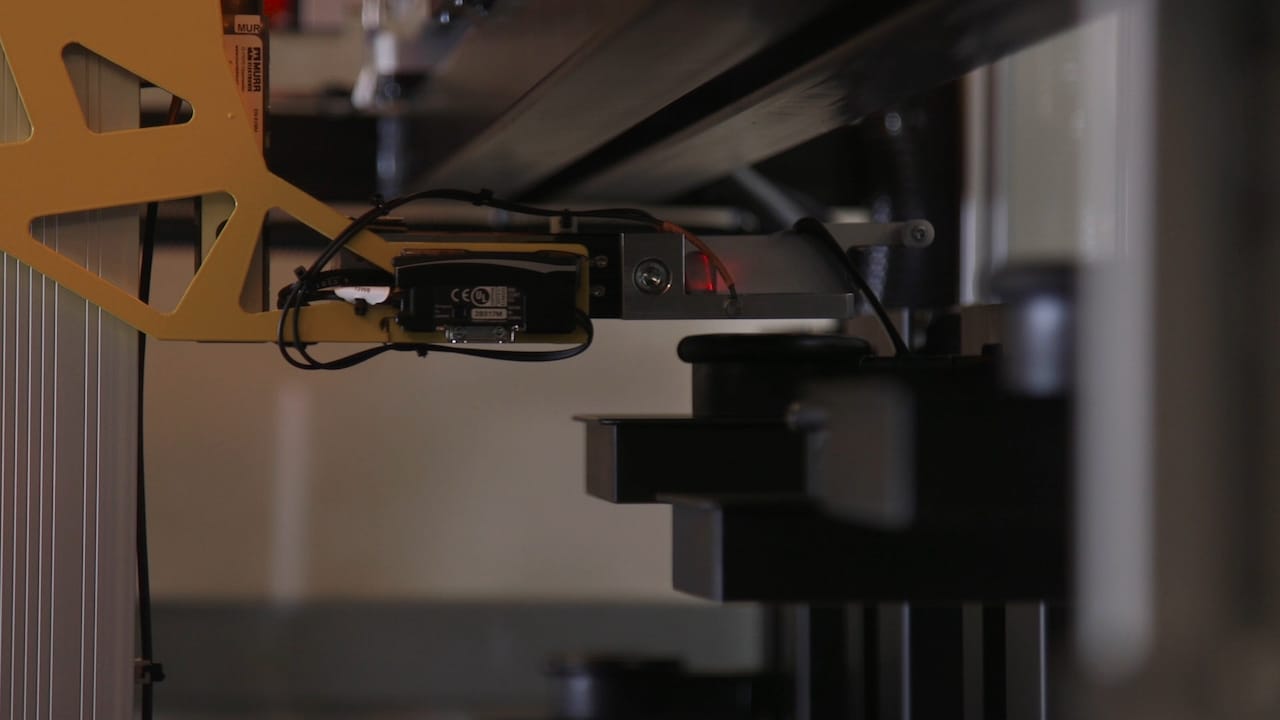

- A robotic arm system to move prints through the subsystems

- A clear acrylic enclosure to provide protection from the moving robotic system

- A management software system to control the activities of all devices

They don’t say so explicitly, but it appears that completed prints are removed from the Form 2 by a robotic mechanism, and then transferred to and through the finishing stations. Finished parts, still attached to the build tray, are collected for manual detachment.

Formlabs claims the system should lower the costs of producing finished parts, likely as a result of reduced labor – the system is automatic. They say:

Optimized for the lowest cost per part, businesses can prove ROI for Form Cell in months instead of years. Form Cell eliminates repetitive manual processes to finally bring 3D printing into the lights-out, 24-hour digital factory.

We haven’t seen many details yet, but apparently the Form Cell tracks jobs through the entire process and even imprints serial numbers on the jobs so that you can identify which print belongs to whom at the end of the production line.

Even more ominous, as I will discuss in a future post, is the fact that the software management system includes a number of programming APIs that enable the Form Cell to be integrated directly into almost any type of factory or customer management system.

One thing we don’t know about the Form Cell is the pricing and availability. And I think there’s a reason for this.

A question I immediately recognized upon seeing this release was whether you can use more than five Form 2’s in the Form Cell. The robotic system appears to be extendable in principle and perhaps you can add additional Form 2’s.

If this is the case, then the price of the system would be variable depending on the size of the final configuration. That may be why they are not mentioning pricing yet. Or it could be they are still working out a viable price based on beta tester feedback.

Like their new Fuse 1 SLS 3D printer, the Form Cell is dramatic departure from Formlabs’ current markets. I’ll discuss this further in a future post.

Via Formlabs