Over the past few years we’ve always advised those with desktop 3D printers to ensure appropriate ventilation is present.

The reasoning is this: it is well known that 3D printers emit particles into the environment, as heated plastic tends to throw tiny bits into the surrounding atmosphere where they can be breathed in. Is this toxic? No one knew for certain, but proper ventilation could certainly minimize any effect.

Now UL has published a set of abstracts for papers presented at a recent conference where such matters were discussed by actual scientists. Their preliminary conclusions suggest risks are present, but not significant. Here are some quotes describing the work.

The crux of the issue is described here by Dr. Barry Ryan, of Emory University:

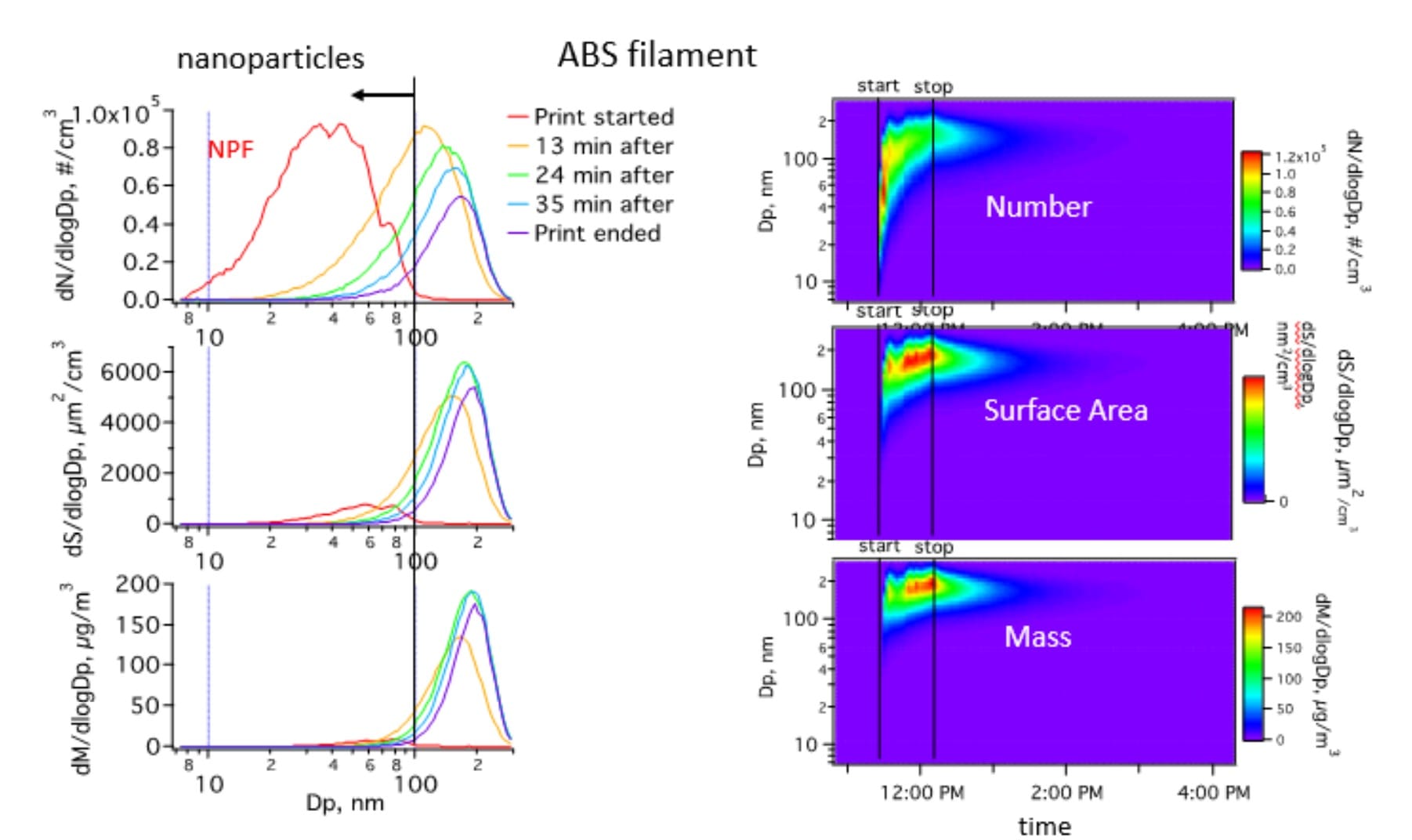

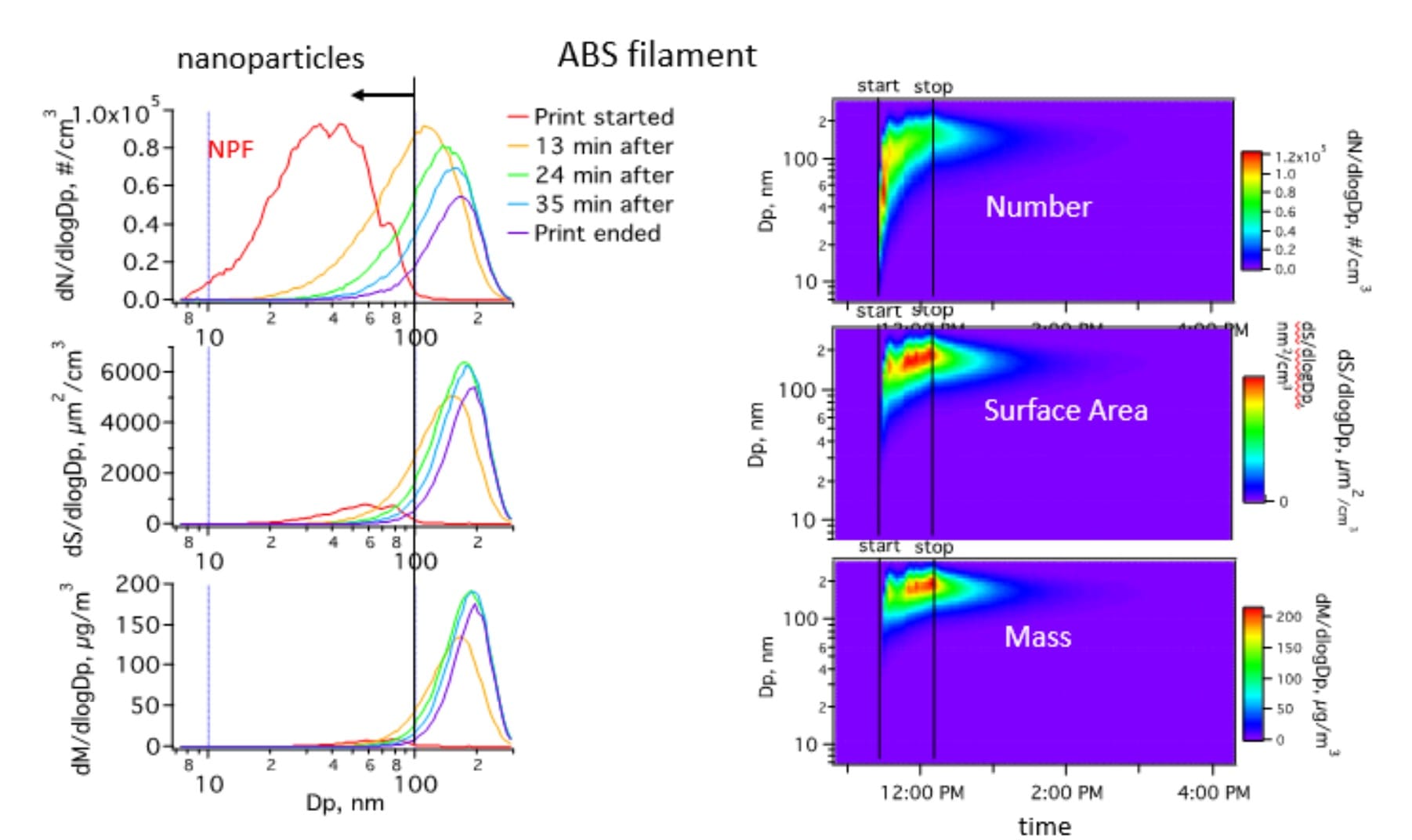

3D printers emit particles primarily in the size range of 50-700 nm, in the middle of the minimum deposition range noted above. Such particles penetrate deeply into the lung, reaching the alveoli and potentially penetrating the lung epithelium. Here they can result in irritation, respiratory effects, and changes in blood chemistry that may precipitate cardiovascular effects.

The results from the modeling exercise suggest that emissions from 3D printers contribute to the total particle concentration in these scenarios, but that the contribution is small. In the worst case, particle concentrations increased by about 1 μg/m3 above an expected baseline of 10 – 20 μg/m3 with the largest increases occurring in the room containing the printer(s).

Future work in this area focuses on two aspects of particle emissions. First among these is the toxicity of the particles themselves. The second aspect of future work is to consider particle surface area, rather than concentration, to be the key to understanding the health impact of exposure.

Some other highlights:

ABS Plastic is Worse: From an ABS printer, the total ultrafine particle emission rate was 1.9 x 1011 particles/minute, and for a PLA printer, the total ultrafine particle emission rate was 2.0 x 1010 particles/minute.

Stopping Emissions: Some potential control strategies for 3D printer emissions include: upgrading central HVAC filtration with a higher efficiency filter impregnated with activated carbon; operating a portable, stand-alone air-cleaner in near-distance zones with a clean air delivery rate of 100 or 300 m3/hr; installing spot ventilation systems in near-distance zones; and creating custom-made enclosures.

Use of Printer Covers: Four ABS colors were analyzed – natural, blue, red, and black. Four PLA colors were analyzed as well – ocean blue, transparent blue, true red, and army green. All of the following total volatile organic compound (TVOC) emission values were from printers with their covers on and with replicate prints of a comb. These printers were also tested with a cover on versus cover off, which showed no effect.

Physiological Effects: Exposure to the emissions from printing with ABS filament have shown increased mean arterial pressure, increased arteriolar tone, and decreased endothelium-dependent arteriolar dilation in

mice.

Genetic Risk: We used a PCR array to screen 84 oxidative, stress-related genes following the incubation of cells with TiO2 nanoparticles. At the concentrations used, standard measures of cell viability (MTT, LDH, and PI assays) showed no decrease in cell health. However, the PCR array showed that four members of the peroxiredoxin family of anti-oxidant enzymes were

altered by ~50%. These enzymes, responsible for the clearance of peroxides from the cellular milieu, are essential to the oxidative stress response of cells.

Volatile Organics: Overall, specific VOCs emissions were a function of filament composition and filament brand. The specific color had a minimal effect. Limited studies with printer enclosures and presence of internal filters also had a minimal effect on emissions and levels. For most filaments, there was a complex mixture of VOCs emitted for each type. There were some individual chemicals of concern that exceeded recommended exposure levels for indoor environments, particularly for personal exposure scenarios for operators or close observers of the machines.

And there’s much more, especially in the papers themselves.

The point here is that there is clearly a risk, although perhaps low, but that also more research is required to identify specific effects and develop solutions.

In the meantime, keep that air ventilation going!

Via UL (PDF)