I’m looking at a new release of 3D print management software from EOS, and had a thought about what makes great tools.

The purpose of 3D print management software is two-fold. First it must transform the raw 3D model into an executable stream of GCODE for the particular 3D printer involved. GCODE is the only “language” 3D printers and other CNC-style machines can understand.

The second purpose is to transmit the GCODE to the specific printer and monitor & control the subsequent print operation.

These two functions are bundled into 3D print management software for all types of 3D printers, from the smallest desktop unit, to the largest machines you can acquire. The software comes from manufacturers, third parties and open source projects.

All parties enhance their software from time to time. Sometimes the improvements are visible, while others are buried deep inside to provide some technical advantage.

But what are those improvements? I’ve noticed two clear patterns of engagement by vendors.

One pattern I’ve seen is one of increased control.

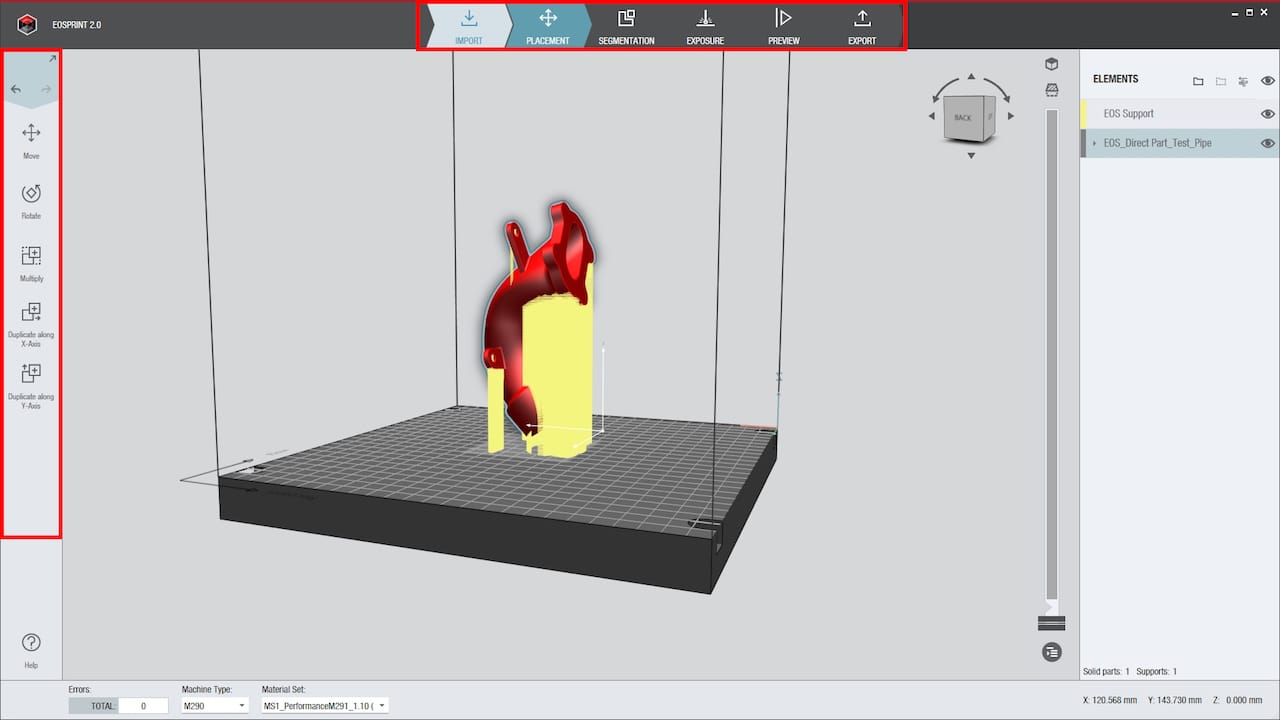

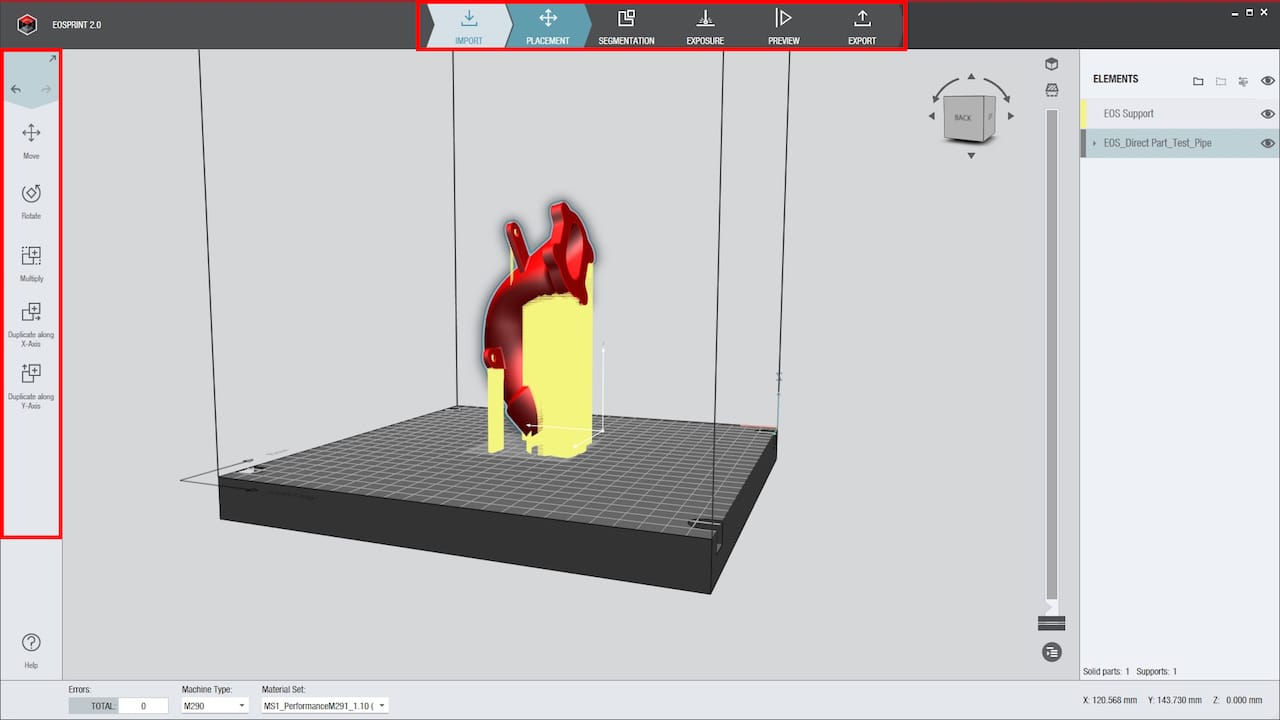

In this pattern software is enhanced to provide more detailed control over specific 3D print operations. For example, in EOSPRINT 2.0, they list these improvements:

- Be more productive with the new plane segmentation and significantly increase speed.

- New exposure patterns and parameters enable unseen part quality at lowest cost per part.

- Open EOS ParameterEditor module allows even greater freedom for application-specific parameter optimization.

- Workflow-based user interface reflecting the AM CAM process makes it intuitive and quick to learn

Notice something? Most of these new features enable operators to adjust the print settings to achieve better quality prints, ones that best match their intended use.

I’ve seen similar features in software from other manufacturers. For example, Stratasys’ Fortus software permits you to make additional extrusions around holes to make them stronger, if you want. You can also play with the internal infill patterns to optimize strength in various ways.

These are all about making better parts by leveraging the intelligence and capabilities of the software operator. The operator is expected to know what to do, and is given the tools to do so.

The other improvement pattern is entirely different. It’s about ease of use.

In these improvements, changes are made to simplify the operator’s tasks. Screens are simplified visually, workflows are automated and more emphasis is placed on the aesthetic qualities of the user experience.

This second pattern is the opposite of the first; it assumes the operator knows little about the task and does not wish to know more. It leverages the intelligence and capabilities of the manufacturer, not the operator.

These patterns address two different types of 3D print operators: professionals and consumers.

My wish is that 3D printer manufacturers issuing or recommending software for their equipment know precisely which kind of person they are addressing. If the wrong choice is made, then you can expect disappointment, even if the hardware is good.

Via EOS