A company is developing a method of providing “invisible watermarks” to 3D prints.

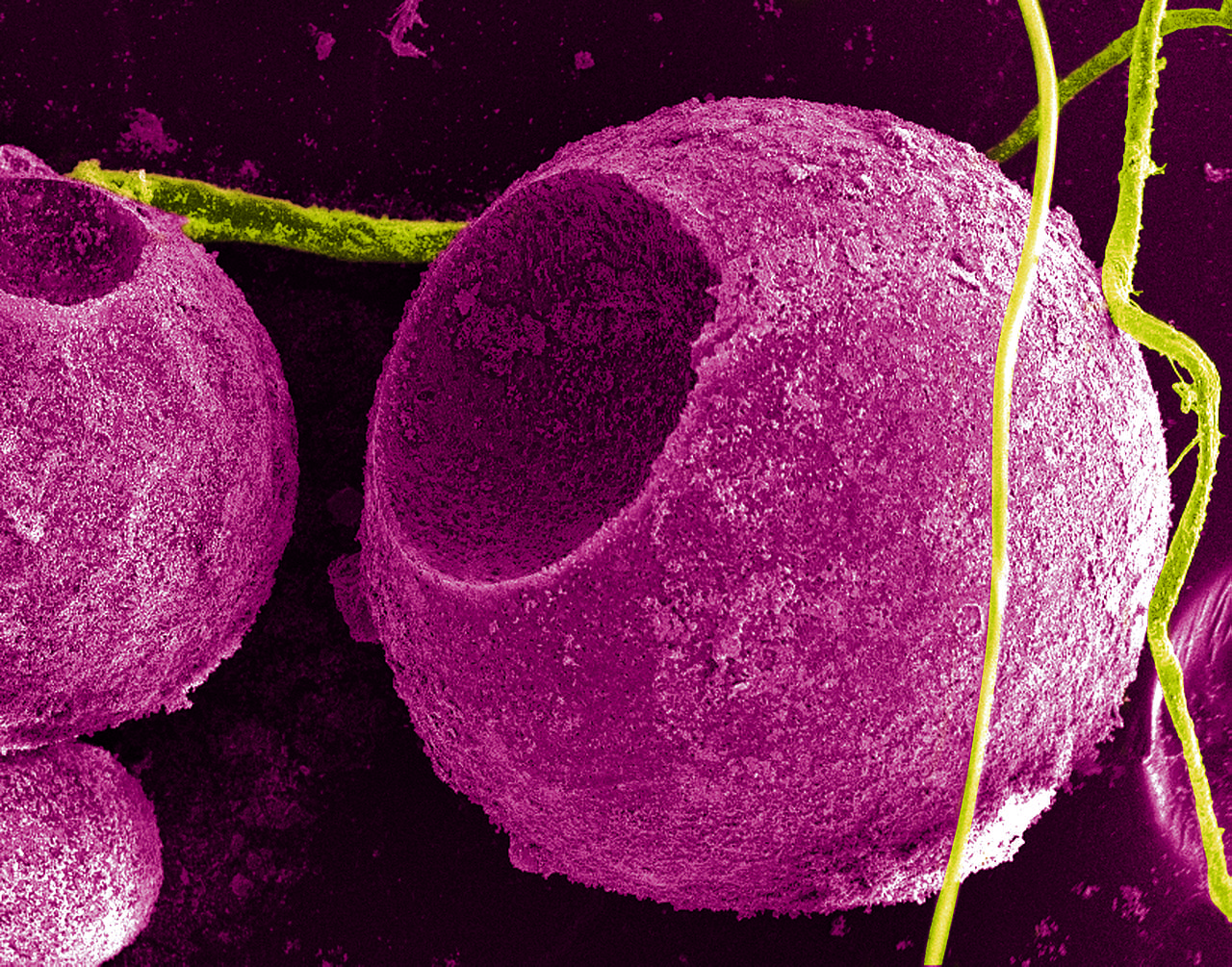

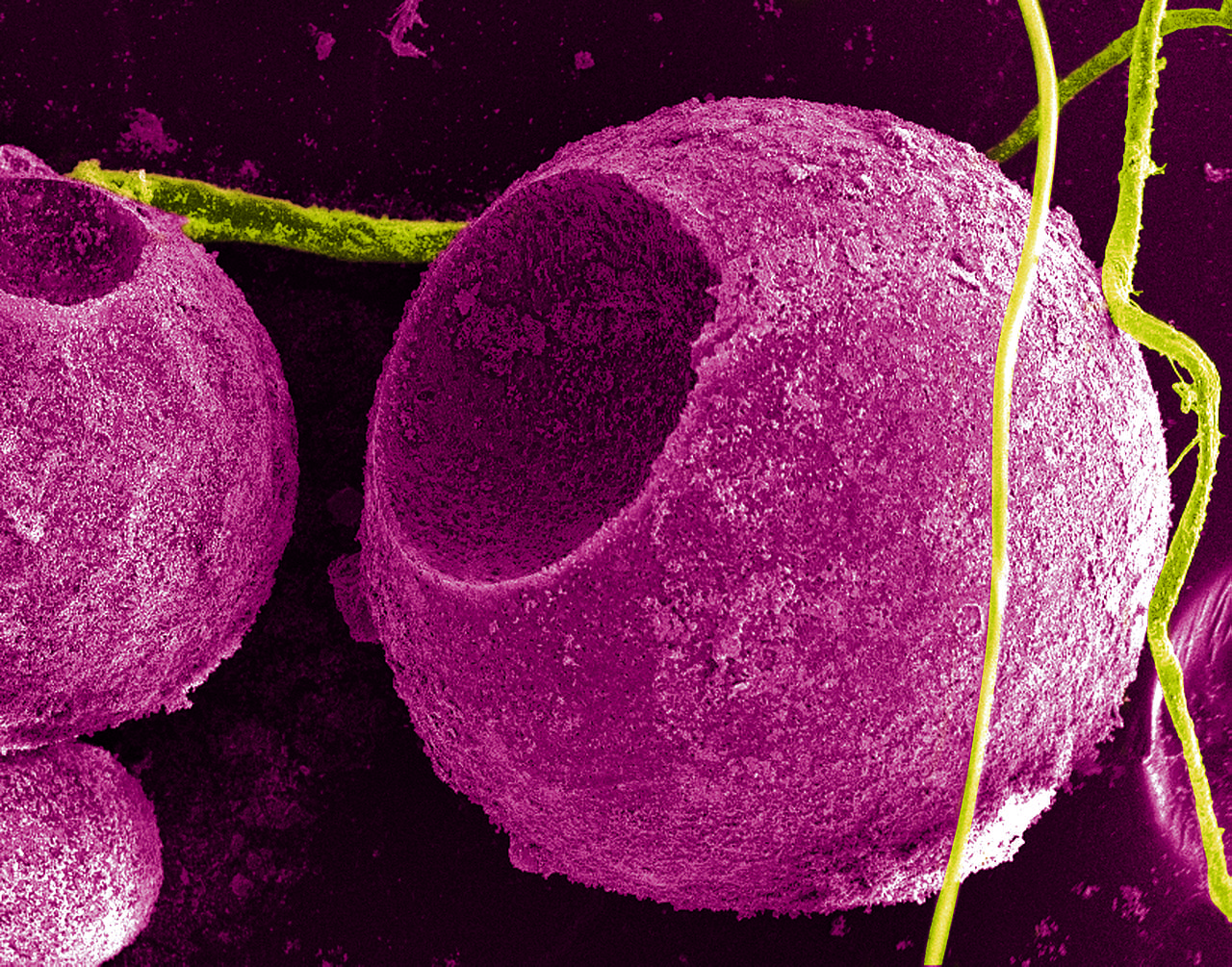

Quantum Materials is working on such a process that involves quantum dots, which are very tiny semiconductor components that are so small their behavior is affected by quantum effects. Quantum dots can emit particular frequencies of electromagnetic wave radiation (light) depending on their configuration.

The idea here is to embed such particles into the material of 3D prints so that the prints can later be specifically identified. They explain:

The goal is to develop abilities to embed quantum dots within objects being 3D printed to produce a unique, physically uncloneable signature known only to the object’s manufacturer. This new quantum dot security method will help to ensure positive identity of any particular object through a wide variety of application and detection methods.

But wait, how does this actually work? They explain further:

Quantum Materials offers unique semiconductor nanomaterials that physically increase these security measures by not only emitting different colors of the spectra from blue to red, but by using tetrapod quantum dots with precise structural characteristics, or dual emission tetrapods that can emit two different colors. The combination of unique process and nanomaterial dramatically improves the security strength.

So it seems they are mixing in configurations of quantum dots into the material. They don’t explain how this is done but I have some speculation.

The quantum dots could be mixed in with the material before printing. This would enable verification of particular materials. So for example, you could shine a detection pulse on a given 3D printed part, and receive back a code that verifies the material in the part is “Stratasys ABS Version XYZ” or similar. This would be quite useful in industry where material confirmation is part of the quality process.

Another possibility is that the printer itself could inject the quantum dots during 3D printing. The printer could have a “serial number” that would be pasted into the object via quantum dots. Then any given part could have its originating printer identified. This would be possibly useful for police investigations, and perhaps police TV episodes.

A more interesting possibility is if the printer was able to change the quantum dot mix during printing. This could enable each individual print (or even object) to hold its own identifying code, making it possible to track objects for their entire lifetime, like tagging livestock at factory farms. An aerospace maintenance worker could theoretically wave a detector at an airplane and receive a complete, accurate and instant list of the specific individual parts making up the vehicle.

However, I suspect we are nowhere hear such a capability at this point. But one can imagine it happening a few years from now.

Via Quantum Materials

Image Credit: Wikipedia