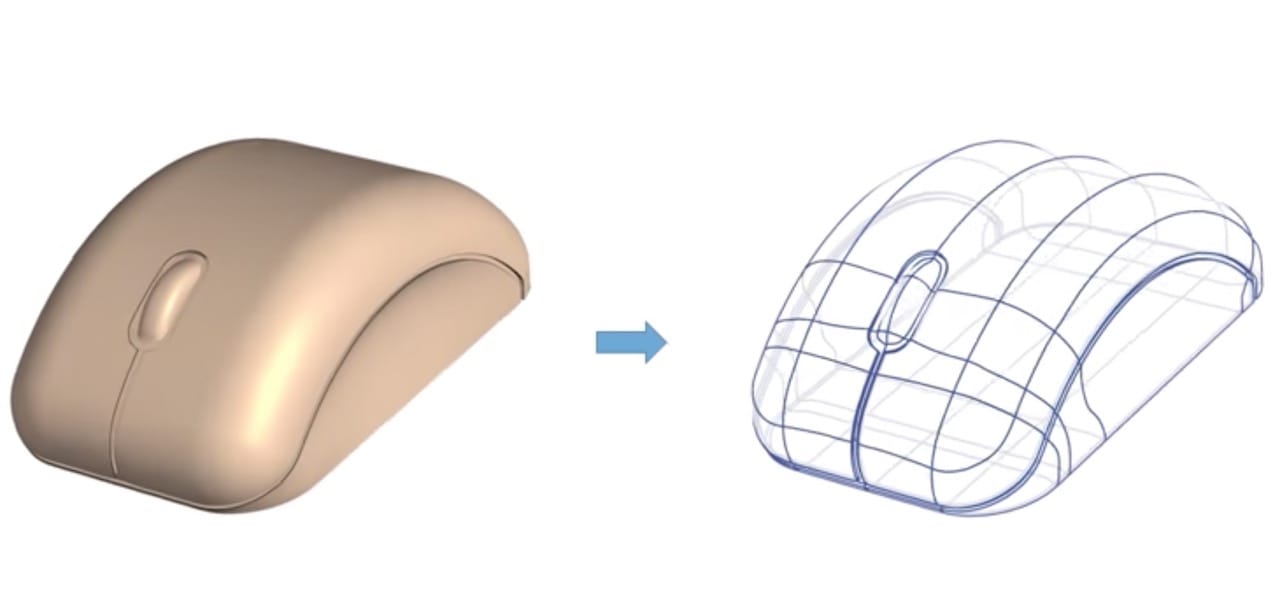

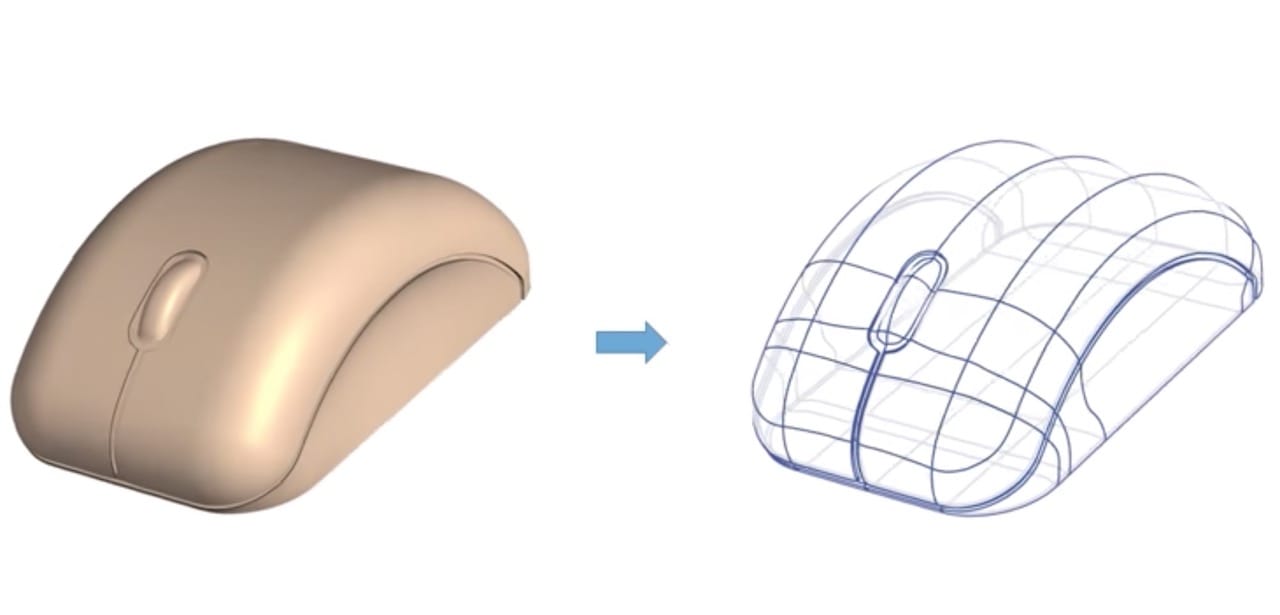

Researchers at UBC have developed an incredible system for capturing 3D models from static images.

The system, called FlowRep, attempts to identify “flows” or continuous aligned curves, from an image. FlowRep’s algorithm apparently leverages techniques used by natural systems to recognize patterns.

Essentially you present an image to FloWRep and it will reproduce a set of curves that are frighteningly close to the original subject. They say the curved shape can be as close as 0.3% to the original object, as measured by the bounding box.

This is surely a fascinating way to capture objects in 3D, but I am startled by the potential within the 3D printing community.

You see, the captured curves are essentially a 3D CAD model. There is little doubt such a capture could be easily reformatted into a file compatible with various CAD packages. Even STL would be possible, enabling one to theoretically “3D scan to print”.

Certainly you can 3D scan objects today using existing equipment, but there is a massive difference here.

Today’s 3D scanning systems are essentially “raster-style” approaches, where individual points are located in 3D space using one of several techniques (optical, laser, etc.) and then a surface is constructed.

The problem is that the surfaces of such 3D scans are rough, as the 3D scan accuracy will never capture a flat or curved surface properly. If only that collection of points in a roughly curved path could be made into an actual curve!

Today that is done by re-engineering the CAD model. Basically the rough 3D scan is imported into a CAD system, and a true CAD model is “traced” on top of the scan. When the 3D model is completely developed from the scan, the scan itself is thrown away as you’ve replaced it with a 3D CAD model you can actually manipulate and enjoy its smooth curves and truly flat surfaces.

But it appears that FlowRep could do away entirely with that re-engineering step. The “scan” goes directly to a CAD-like 3D model. That is a massive step forward.

If FlowRep was built into a mobile app, for example, it would mean that consumers could literally capture a 3D CAD model of any nearby object, not just a rough 3D scan. They could then manipulate the CAD model in desired ways, if they were able and inclined to do so.

Today’s 3D scan systems are often challenging to use and produce results that in almost all cases require additional work before proceeding. FlowRep could simplify that workflow tremendously, making it conceivable that more consumer 3D printing could take place.

Via Digital Journal