A question that is sometimes not even asked, let alone answered, is the question of outsourcing 3D printing.

Outsourcing occurs when you contract with another party to execute your 3D print activities. This would certainly include formal arrangements between firms, but would also apply to 3D print services such as Sculpteo and Shapeways.

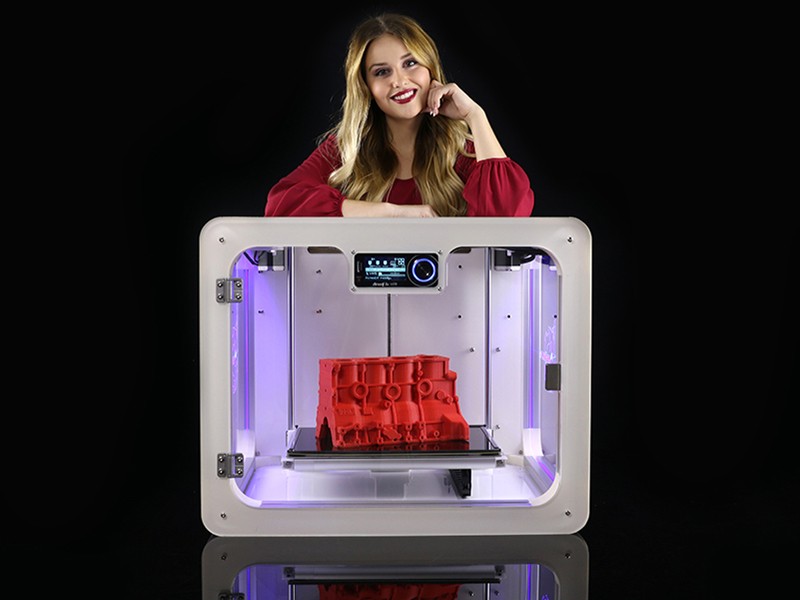

Insourcing occurs when you decide to operate your own 3D printers and associated equipment within your own workshop. This again could mean a large, professional workshop with all the latest equipment, or it could also mean the table behind your desk in the basement. If it’s yours, it’s insourced.

A common scenario I encounter is that a company decides to “get into” 3D printing and simply orders some equipment. It may or may not be the right equipment. It may be expensive, or it may be too cheap. But it’s insourced, and whatever comes from the experiment may be good or bad.

Another common scenario is that a company for some reason assumes they cannot operate their own 3D printers and constantly uses 3D print services, even though the costs and time delays to obtain parts may be excessive.

Both of these scenarios could be wrong for some companies. At any point in the lifecycle of using 3D printing, a company’s best configuration might be “in” or it could be “out”. It could be both, as well. And this “best configuration” could change over time as volumes, requirements and costs evolve.

The advice I tend to supply enquiries is simply this: if you are starting down the 3D print trail, most definitely start with a 3D print service. Yes, a 3D print service could be more expensive, but only on a per-part basis.

If you decided to go the other way and buy your own gear, you may make a mistake, particularly if you are new to the game. The best approach is to experiment with 3D print services until you are sufficiently familiar with what you really get from 3D printers.

Then you may consider that you’re paying the 3D print service more than it would cost you to do the same work in-house. At that point you should consider acquiring your own gear. You will have the confidence and knowledge to effectively select a machine of your own that will provide the correct type of print at the right price.

Even after you’ve insourced, there will be cases when you need to invoke 3D print services. For example, perhaps you’ve established your own plastic 3D print operation and you are considering adding a 3D metal printing system. Don’t! Use a 3D print service first for a while to learn more about it, and then decide if you need one yourself.

Make the smart choice: rent someone else’s machine before buying your own.