We haven’t written about MakePrintable for a while, but today is a good today to do so.

Why? It’s because the company is switching their repair algorithm in a very significant way.

Let’s back up a bit: if you haven’t heard of MakePrintable, it is a web-based service that provides an ability to repair misbehaving 3D models. As you may know, the STL file format is very deficient in that it is very possible – and frequently encountered – that a given STL format 3D model is a valid, syntactically correct file, yet the 3D model it represents is wholly unprintable.

This is because 3D prints are of solid objects, and thus you need a true, solid, watertight digital 3D model as input.

Unfortunately STL files have a myriad of ways to get it wrong. While STL ostensibly describes an object as a skin of perfectly connected triangles. That often isn’t the case, particularly when the 3D model is designed for visual use, where the notion of solidity is not required. Triangles can be disconnected, missing, overlapping and flipped.

Such misaligned STL files confuse 3D print slicing programs and the printed results can be inefficient, incorrect or even can fail.

Thus the need for STL file repair systems. There are many options to do so. Many people have used NetFabb for this purpose over the past years, but there are some pathological STL files that are too confusing for repair services to work through.

I’ve often used several different repair tools in sequence for this reason; one tool can “see” the 3D model in a different way and can figure out a proper solution. You just have to find the right one.

This frustrating experience is something many 3D print operators have seen and become familiar with.

But that may change with the change at MakePrintable, whose web-based service allows upload of arbitrary 3D models and cloud-based repair.

The service launched many months ago and has been reasonably successful. But, like many other repair systems, their algorithm was baffled by some mangled 3D models.

In the past few months, MakePrintable has been testing an entirely new algorithm they call “Mammoth”, named for its ability to handle gigantic, highly complex messy 3D models. They explain:

Mammoth uses the size of the microns and scale of the print as an indication to the resolution it should use for processing for that it does accurate processing of your 3D files to match with the microns of your 3D print thus generating accurate adjustments to your file where it needs to, this means that it can do accurate wall thickness adjustment to only the areas that needs wall thickness adjustment. Another advantage to mammoth is that you can control the polygon count of the generated 3D file and it is even possible to reduce it beyond the original polygon count without causing 3D printing issues due to the decimation process.

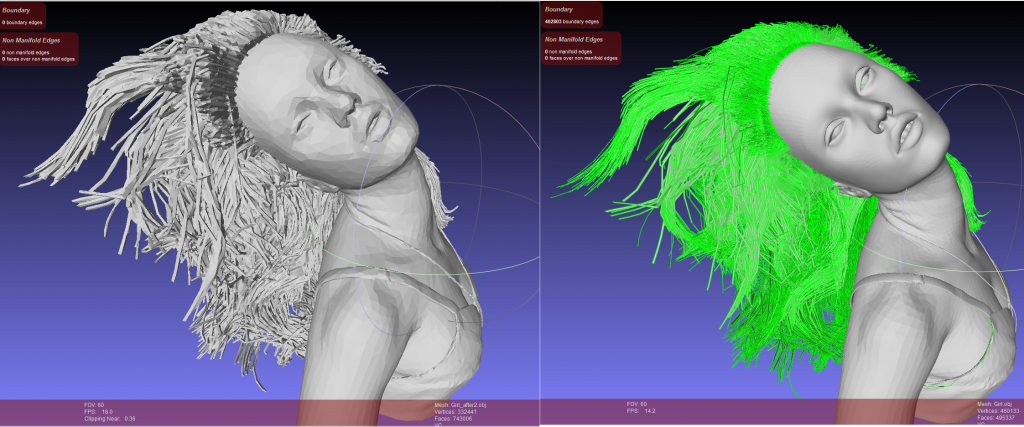

It seems that the algorithm is voxel-based, rather than trying to figure out what the misbehaving triangles were attempting to describe. This seems to result in a much more accurate reconstruction of the 3D model. They even got a repair to work properly with a 3D model of someone’s hair, which is ridiculously complex.

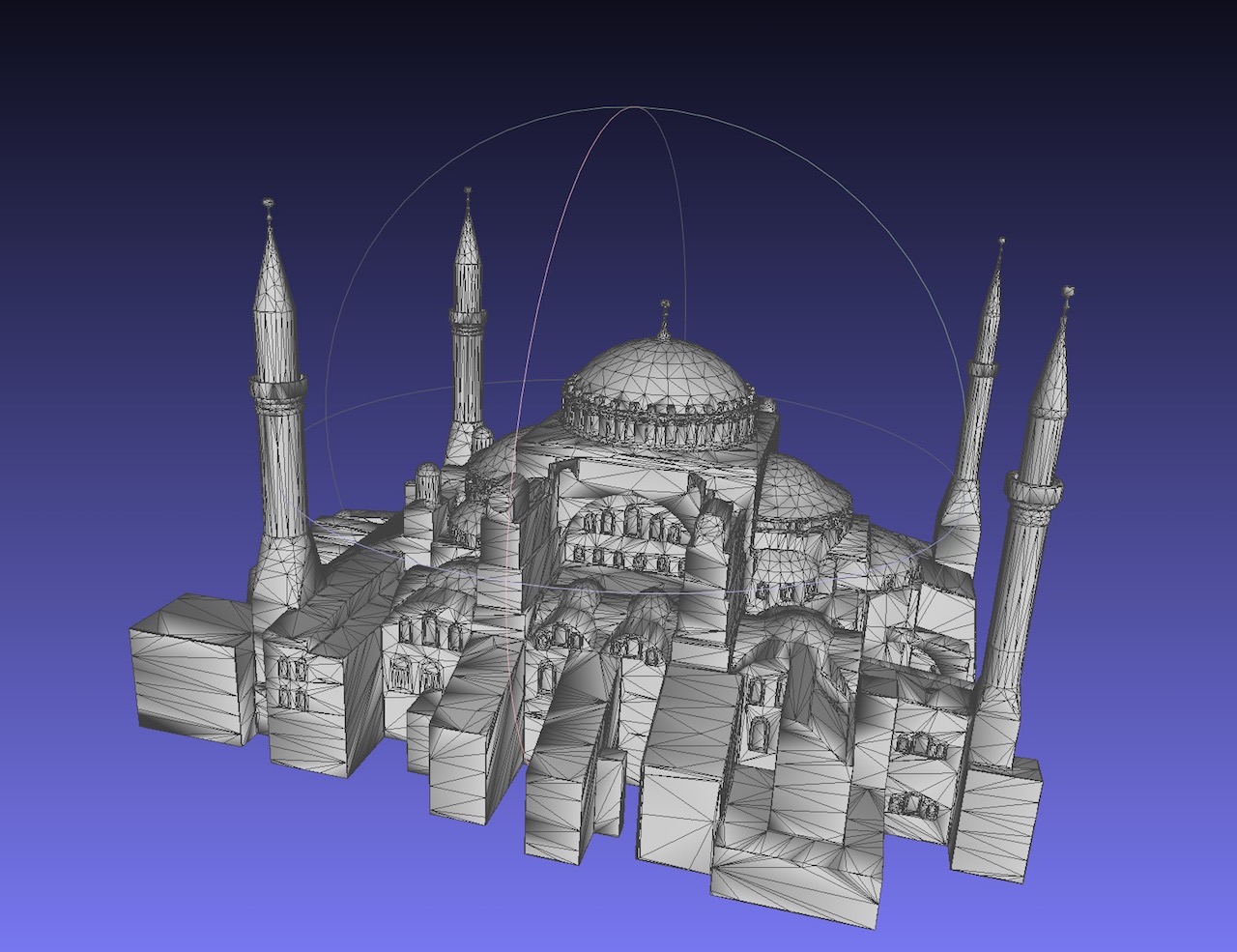

I tested the new algorithm by throwing at it an old 3D model I had never been able to properly repair, one originally made in SketchUp for visual display purposes only. It was entirely unprintable, and apparently, unfixable.

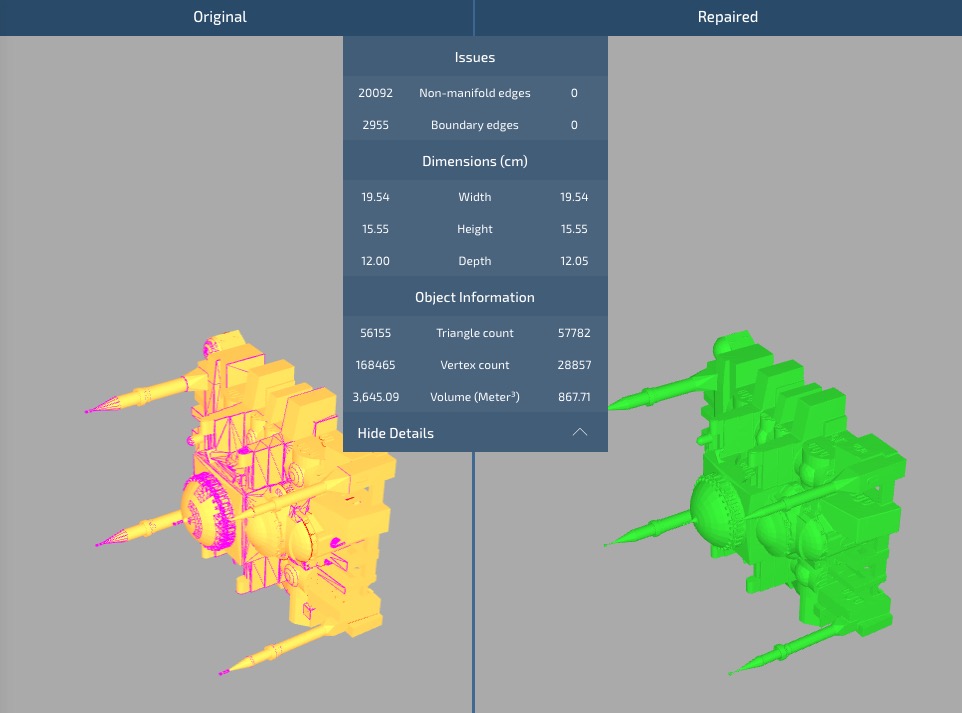

The new MakePrintable service accepted the 3D model and went to work. After only a couple of minutes, a far shorter time than I expected, it completed the repair. See the results at top.

And incredibly, it was perfectly executed! This messed up 3D model had been transformed into a perfectly solid 3D model, ready for action. Well, there was one problem: the bottom of this 3D model turned out to be not flat, so I had to do a plane cut to make it sit properly on the print plate. But that isn’t something MakePrintable should or would fix in any case.

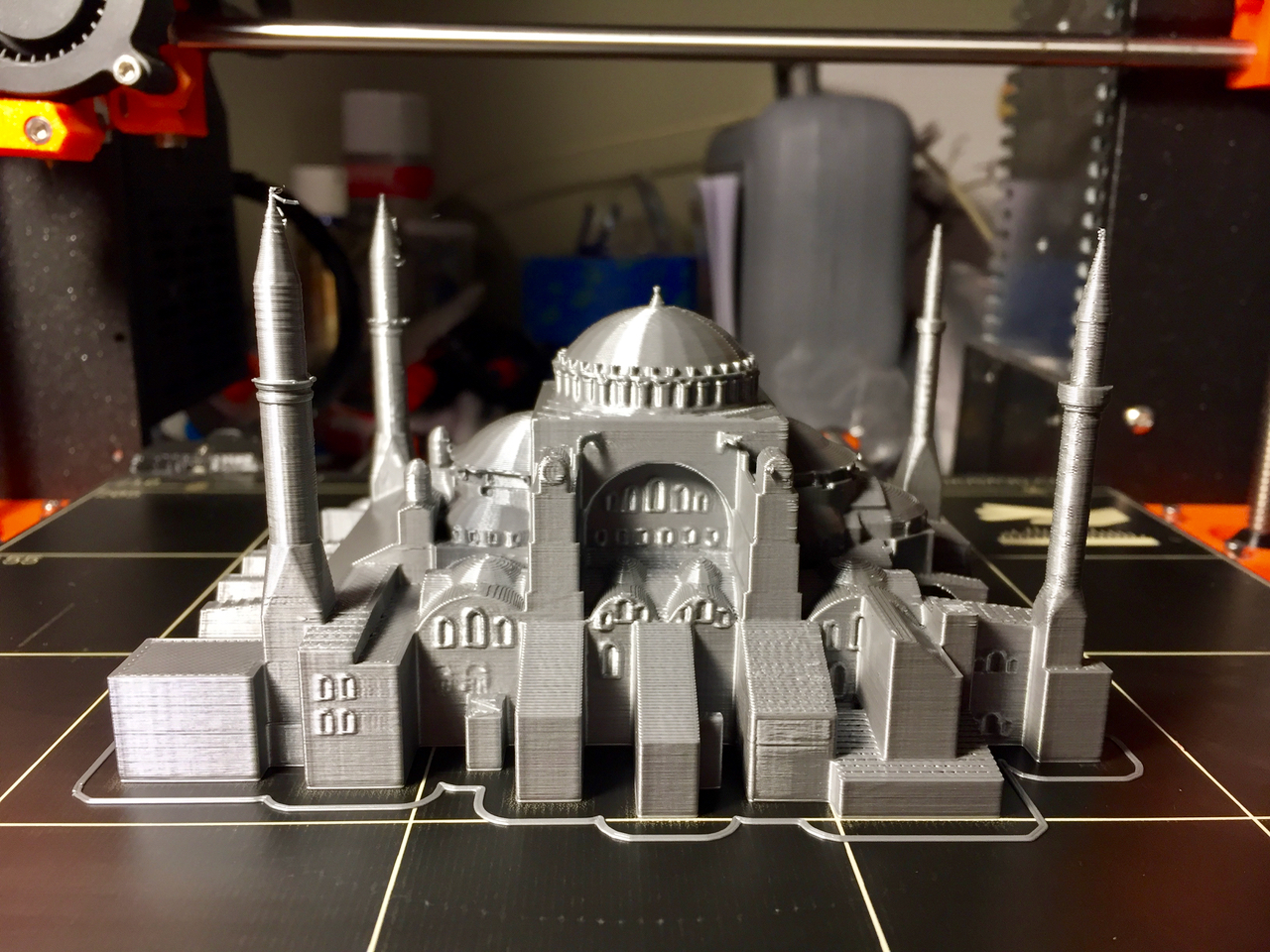

In fact, I quickly 3D printed it and the results were excellent, as you can see here.

This new approach appears to be extremely powerful: it produces accurate results as well as doing so quickly.

One very big implication of this development is that it may now be possible to unleash a massive amount of pre-made 3D content currently stored on visual-oriented 3D model repositories. While there are 3D model repositories for solid models suitable for 3D printing, like Thingiverse, there are vastly greater – and dare I say more interesting – content repositories containing visual 3D models that are largely unprintable. Look out, TurboSquid!

Until now.

MakePrintable’s new algorithm could shake things up substantially.

I’m told the service will now use the new algorithm as its default standard starting today, making this feature available to everyone.

If you have misbehaving 3D models you might give MakePrintable a try. One caution, though: it is a paid service, unless you repair only up to three 3D models per month.

Via MakePrintable