An interesting liquid solution for ensuring 3D prints “stick” is available.

Dimafix, a product of Spanish company DIMA 3D Printers, is a temperature-activated liquid solution that can help avoid catastrophic warping during 3D printing.

If you’re 3D printing any material that shrinks more than a little bit while cooling you will be susceptible to warping. In the best cases the 3D printed object will be slightly malformed, typically at the corners, which may lift slightly.

A worst case is that the warp causes so much of the print to separate from the print surface that it actually detaches entirely and is tossed about the build chamber by the moving toolhead, potentially causing fatal damage to your device.

Usually the problems are somewhere inbetween, and manufacturers have striven to identify effective solutions for this malady.

Heated print surfaces were the first reasonably effective solution, but even they often failed pathologically misbehaving materials such as ABS. Thus a market opened for third party solutions to help with the problem.

There are plenty of solutions available. One common “homemade” approach is to dissolve a bit of ABS plastic in acetone, then wipe the print surface with the solution. The acetone dissolves, leaving a thin coating of ABS on the print bed, which prints adhere strongly to. However, removing the print can sometimes be challenging.

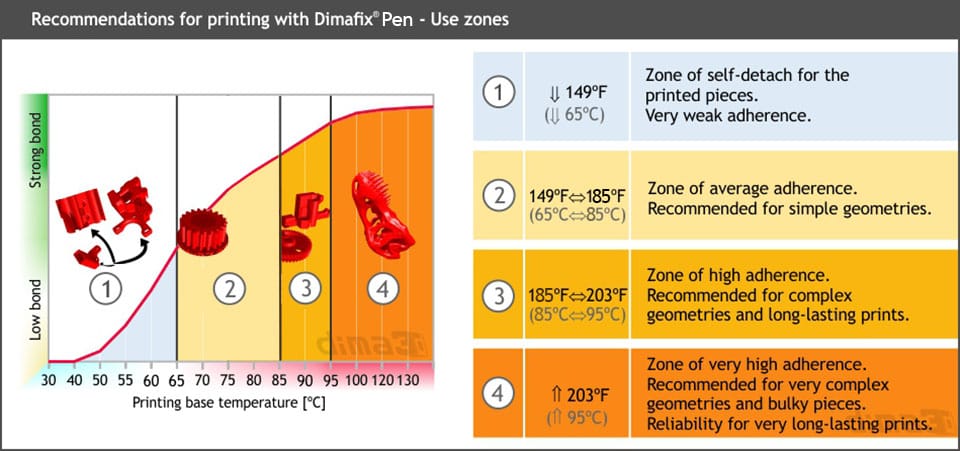

The product in question here, Dimafix, is interesting in that it is temperature activated. Here’s a chart of its adhesion properties (for the pen version, the spray version has slightly different characteristics, but it’s the same principle.)

The idea is to apply the substance to your print bed (and Dimafix comes in either a spray, “Dimafix” or pen applicator, “DimaPen”.) After heating the print bed – and the solution – it becomes strongly adhesive.

When the print completes successfully, you simply wait for the bed to cool down to below 50C, and the Dimafix releases the print.

It seems like a very straightforward way to corral misbehaving ABS prints on many 3D printers. However, in order to use this product you must have a heated print surface, one that can hit 100C levels.

It’s also water soluble, so it’s easy to remove from your print surface in case you wish to print other materials. Just wash it off.

Pricing of Dimafix is variable, as it is sold through a number of resellers, primarily in Europe. I’ve seen pricing range from about USD$18-24 for single spray cans, which apparently are good for around 100 uses.

If you’re struggling with making your ABS print stick, consider Dimafix.

Via Dimafix