I’m reading a fascinating report on a new way to work with miracle material graphene.

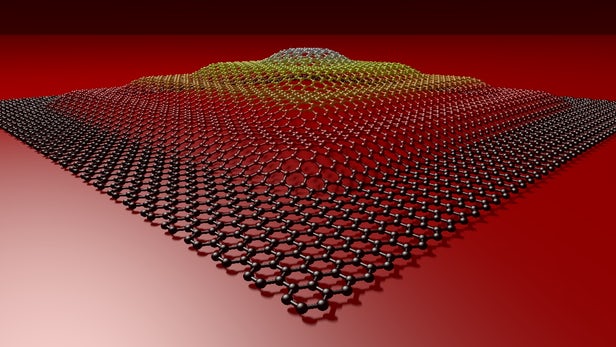

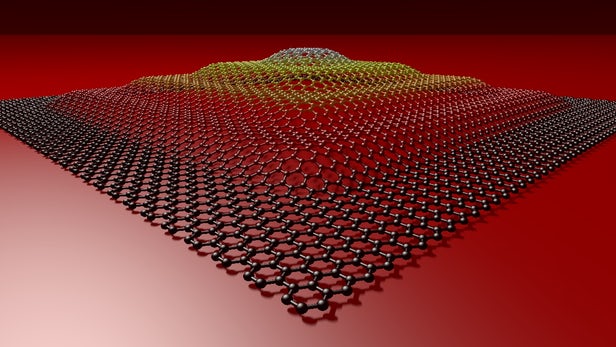

Graphene is a type of carbon that is essentially a flat sheet of tightly hexagonally interlocked carbon atoms. It offers astonishing engineering properties, including: transparent appearance, strength 200 times greater than steel and a high conductor of heat and electricity.

But attempts to 3D print with graphene have been very limited, mostly cornered into using chopped up graphene bits as an additive into standard 3D printing filaments for extrusion. This indeed makes the resulting object stronger, but by no means close to the potential of actual graphene.

The research is interesting. Apparently researchers have been able to perform forging on a sheet of graphene using a laser system. The idea is to have the laser focus briefly on a spot, which causes the material to slightly expand. This results in a warp that bulges into the third dimension.

By varying the application of the laser, the researchers were able to develop a variety of 3D “dents” in the graphene surface.

Apparently the process can introduce bulges 200X the thickness of the graphene sheet itself, and it does not change the graphene or its properties.

How could this be used for 3D printing? That is a very interesting question, as it seems to me that this process is somewhat similar to that used by many 3D printing processes to create layers.

I’m wondering if it might be possible to create graphene layer shapes that could interlock with a subsequent graphene layer? If that is possible, then I could imagine a kind of “graphene sheet printer”, where incredibly strong objects could be produced with ridiculous accuracy.

I have no idea if this is possible, but it’s fun to speculate.

One very slight problem, though: print times would be extreme, as each layer would be LITERALLY ONE ATOM THICK. Thus printing a 20mm graphene cube using this hypothetical process at one second per layer would take something around 625 days to complete.

Oh well, back to the drawing board.

Via New Atlas