3D print middleware utility service Authentise is working on an interesting new function: Watermarking.

Authentise is known for their 3Diax manufacturing solution, which provides a series of functions related to the movement of 3D models and 3D print streams within and between businesses. While most 3D printing concepts focus on the “modeling” or the “printing”, Authentise works on the stuff in-between.

By acting as a networking middleman, Authentise is able to provide a wide variety of functions, such as tracking 3D models and prints, providing security, streaming prints to avoid loss of 3D models, etc. But now they are working on something new and probably quite desirable to many design firms.

The technology is watermarking, in which a “tell” is inserted into the product for later identification. This is very commonly – and visibly – done on photographs. You’ll often see a faded overlay on a particularly popular image to ensure the original photographer retains credit to the work.

This same process is also useful in 3D printing, as the digital 3D models are subject to theft just as photographs can be.

Authentise has partnered with ProtoTech, an Indian software firm, to develop the complex watermarking solution. Evidently the function is not yet available, but they are working on it.

I say this is complex because the notion of embedding a watermark in a 3D model is a bit different than simply pasting a graphic on a photograph. Where do you put it? What is the watermark? So many questions.

Authentise explains a bit about their goal:

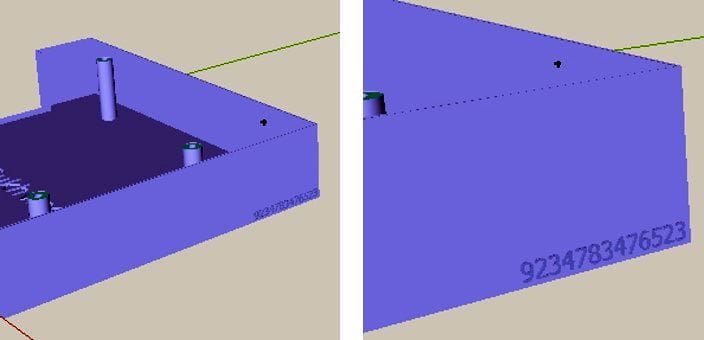

ProtoTech will exclusively offer its watermarking technology through the 3Diax platform and Authentise will market the technology as the 3Diax Watermarking Module. The Module enables serial numbers, barcodes or other identifiers to be embedded at any point in the geometry – on the part, in the support structures, on an attached tag, and even below the surface so that it can only be detected by X-Ray or similar technologies. This enables more efficient and reliable tracking and sorting of parts within factories. It also has the potential to significantly speed up supply chain and reduce the number of counterfeit parts in circulation.

I find this quite fascinating, because it could have big implications on the future of manufactured parts. Today it is possible to obtain “third party” parts from manufacturers at lower cost, but sometimes these get accidentally (or purposely) mixed with genuine parts that are higher cost. If there were a reliable way to identify a genuine part, this situation would get straightened out quickly.

However, that won’t happen until a large portion of parts are 3D printed, simply because the watermark cannot as easily be arbitrarily inserted using conventional manufacturing processes.

Via Authentise