A research report puts doubt on the notion of “eco friendly” 3D printing.

The report, by Daniel Posen, Paulina Jaramillo1, Amy E Landis and W Michael Griffin, examines the idea of mitigating greenhouse gas production by swapping out traditional plastics and substituting bio-sourced plastics. While this idea may appear intuitively to be the correct approach, it turns out it is not.

They also considered the idea of using renewable energy to create plastics, rather than conventional dirty energy sources.

The foundation of their analysis lies on the fact that plastics do not literally “grow on trees”. Instead they must be manufactured in known chemical processes, processes that consume energy.

But because some plastics are derived from biological sources, many in the public may assume they are “green”, but this does not account for the full lifecycle that brought them into existence.

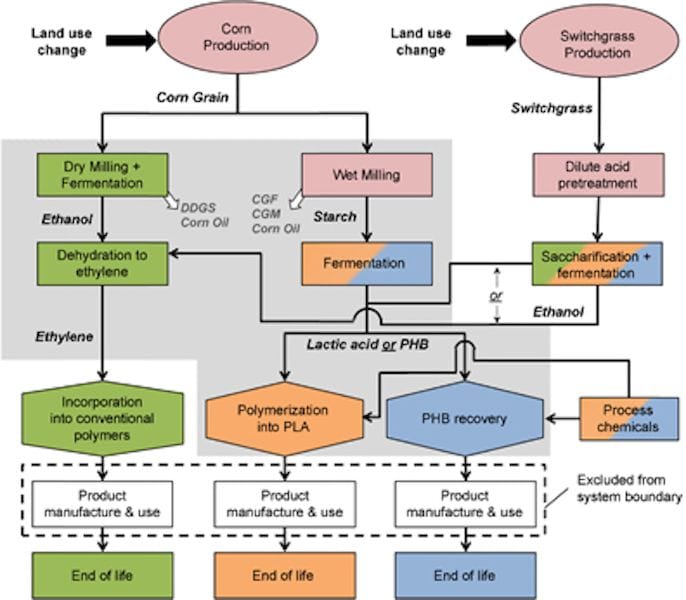

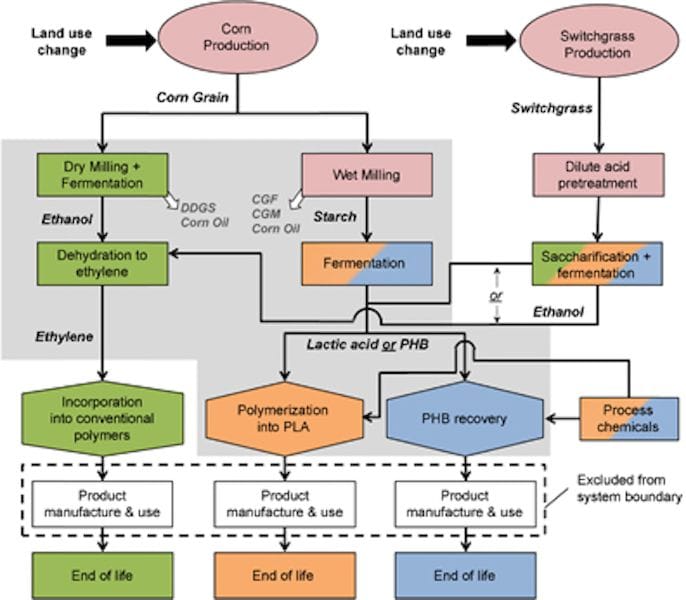

The scientists examined the three main categories of bioplastic, which include the very familiar PLA, PHA and bioethylene based plastics, such as bio-PET. They reviewed the typical processes that are undertaken to create each material, developing costing and greenhouse gas emission estimates for each stage.

They realized that some common assumptions are not necessarily true. For example, one might assume that a part 3D printed in a bioplastic would completely degrade over time. However, in practice such items frequently end up in a landfill, where the deprivation of oxygen means they cannot properly degrade as intended, and may even emit carbon and methane. It’s possible to harvest landfill-generated methane for use as energy inputs into the process, however.

Their conclusions are interesting:

- The industrial agriculture practices used to grow the input organic material (corn) for bio plastics itself uses considerable energy, often based on fossil fuels.

- PLA is not applicable to many industrial uses due to its low thermal properties.

- The disposal methods used by cities are frequently not optimal for the degradation of discarded parts.

- Finally, they demonstrate that it is far more effective for greenhouse gas reduction to make the same plastics using renewable energy sources, rather than switching industry to using renewable bio-plastics.

This tells me something about how some 3D printer filaments are marketed today: they are branded as “renewable” or “biodegradable”, etc. This marketing approach should no longer be used, because in practice it really isn’t true.

A better and more effective marketing approach might be to brand products as having been made with renewable energy. However, I have yet to see a 3D printer material with that labeling.

Via IOPScience