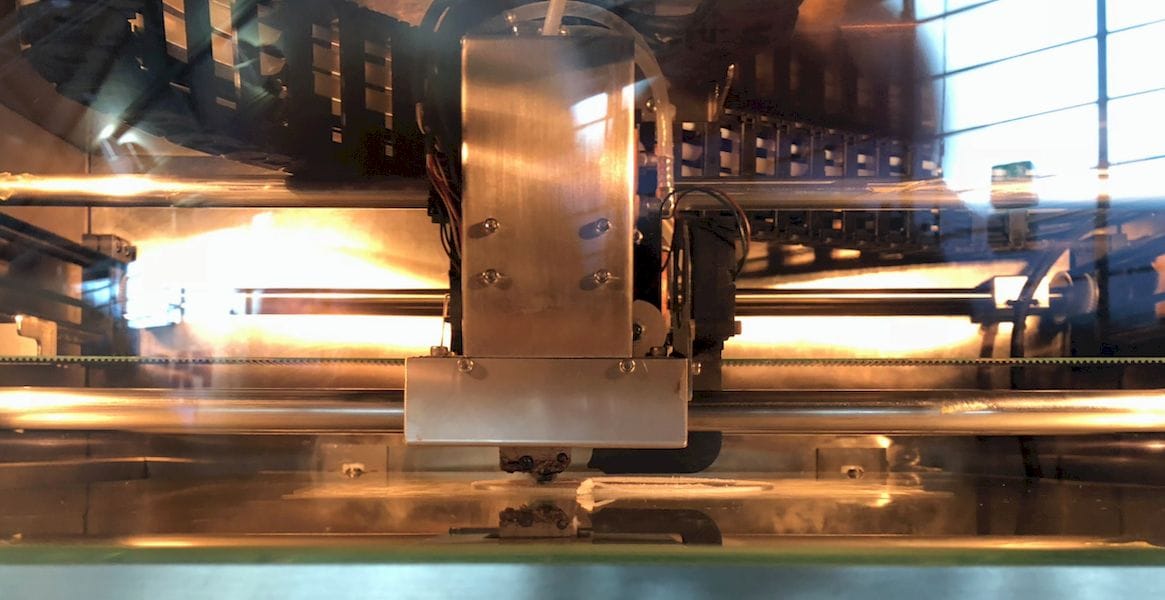

Shanghai-based INTAMSYS’ FUNMAT series of professional 3D printers hopes to provide the world with high temperature capabilities.

The company has smartly focused on the industrial market by developing equipment capable of 3D printing thermoplastics in very high temperatures.

Their FUNMAT series currently holds four different models, all of which sport a heated build plate, filament out detection and monitoring webcam:

-

The FUNMAT 3D Printer: An industrial-grade desktop 3D printer with build volume of 260 x 260 x 260mm.

-

The FUNMAT PRO 3D Printer: A larger version of the basic unit, with a build volume of 450 x 450 x 600mm, and an automated calibration system. This unit also includes upgraded mechanical components.

-

The FUNMAT HT 3D Printer: Mechanically similar to the basic unit, the HT version’s hot end can reach 450C, and the thermally insulated enclosure is able to deliver a “constant” 90C within for added print reliability.

-

The FUNMAT PRO HT 3D Printer: Is essentially the basic PRO unit with the HT high temperature features.

While the non-HT units are easily able to reliably 3D print common 3D printing materials such as PLA, ABS, HIPS, PETG and many other typical materials, the HT machines are more than capable of 3D printing exotic engineering materials such as PEEK, PC and ULTEM, which are typically impossible to 3D print on typical desktop 3D printers.

We’re told their new model, the FUNMAT PRO HT, includes a somewhat more advanced heating system. In this model the build chamber can be raised to a searing 120C, making prints of higher-temperature materials a even more reliable. The heating profile can also be changed on the fly during print operations as well, for even more control over print results.

3D printing objects in warpy materials such as ABS at a minimum requires a heated build plate, and more reliability is obtained when the build chamber itself is heated, as is found in the FUNMAT series. However, it’s still challenging when printing larger objects, where the shrinkage of the material is amplified over longer cross-sections of the object.

This is what is addressed by the FUNMAT PRO HT system: it has a very large build volume, but is able to successfully 3D print troublesome materials like ABS because it has a much higher chamber temperature. Whereas most heated chambers tend to be around 70C, the FUNMAT PRO HT’s 120C is quite a bit higher.

Priced near USD$40,000, the FUNMAT PRO HT is actually less expensive than some competing systems providing similar large 3D print volumes. According to company representatives, they have now enabled worldwide sales.

The FUNMAT series seems to be a very good option for those considering professional 3D printers, especially if there is a requirement for higher temperature materials, like PEEK and ULTEM.

Finally, I was very curious about the names of the products and company, which, to be honest, seem a little bit awkward to pronounce. When asked, company representatives explained they are acronyms:

INTMASYS = INTelligent Additive Manufacturing SYStem

And:

FUNMAT = FUNctional MATerials

I suppose this makes logical sense, what do you think?

Via INTAMSYS