Looking for an interesting 3D metal printing option? Consider Formalloy’s system.

Formalloy uses a different technique for producing solid metal parts than the majority of the 3D metal printer market. Instead of using a powder-bed/laser system, they use a Laser Metal Deposition (LMD) process.

In LMD, there is no “bed”. Instead the fine metal powder is precision jetted out a toolhead where it immediately encounters a powerful laser that melts the material near instantly.

By moving the part and toolhead appropriately, the machine can selectively deposit solid metal to form objects.

In a powder-bed/laser system, the meltpool travels in a two dimensional space: the surface of the powder bed. In LMD the meltpool moves in three dimensions as the orientation changes between the toolhead and part. Formalloy’s machines employ a 5-axis system to create this movement.

There are some advantages to this approach, the most notable being price, as this style of system can be less expensive than powder-bed/laser systems. It can also be scaled up to sizes larger than typical 3D metal printing systems.

Formalloy’s implementation appears quite powerful, as it is capable of producing walls as small as 1.0mm, with its 0.250mm width deposition.

The company says their LMD process can result in “much faster build times” and achieves “superior material properties”.

The LMD process also enables the system to perform cladding, where material is jetted on top of an existing print or part. In addition, you are also able to perform 3D repairs on metal parts by depositing replacement material where, for example, some has worn away due to use.

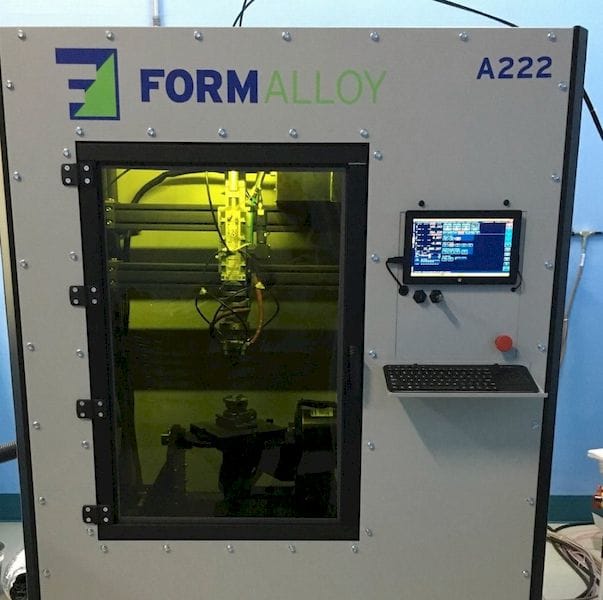

Formalloy provides two different models, the A and L series, each with customizable build volumes. Both machines feature multiple input powder hoppers to enable rapid switching from one material to another. It’s also possible to blend powders together to create new alloys; I suspect this feature may have inspired their company name.

One very interesting item is that Formalloy also makes their LMD deposition toolhead for sale separately. I don’t know of any other 3D metal printer company that does this, as the deposition mechanism is usually the key component in such systems. Nevertheless, Formalloy’s Formax Metal Deposition Head is available for purchase and with it you could construct your own variant of an LMD 3D metal printer.

But be sure to include an oxygen-free build chamber, or you’re asking for trouble. Big trouble.

It seems that Formalloy is quite flexible when ordering one of their systems, as almost all features, including build volume, are customizable. You can include different sized nozzles, scientific monitoring features and much more, if desired.

With all these new powerful 3D metal printing systems coming on the market at pricing far lower than traditional 3D metal printer vendors, one wonders how the market will change.

Via Formalloy