I’m watching an interesting TEDx video on interplanetary architecture and realized something applicable to Earth-bound 3D printing.

The TEDx talk was by Xavier De Kestelier, architect and visiting Professor at Ghent University and Adjunct Professor at Syracuse University, who is actually working on the problem of designing structures for habitation on our Moon, as well as Mars, a very challenging topic indeed.

In the talk, “Adventures of an Interplanetary Architect”, De Kestelier describes how such structures will be made from local materials. The idea is to ensure the bulk of the structure is made from local materials to dramatically lessen the amount of pre-made structure that would otherwise be shipped in a very costly manner from Earth.

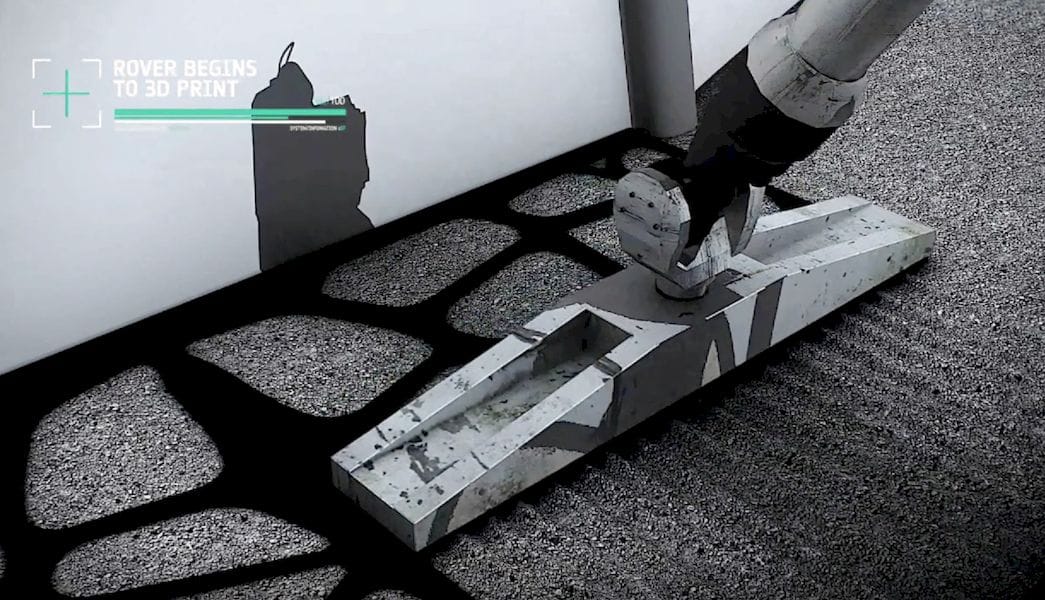

As we’ve written previously such use of local materials would no doubt involve 3D printing technologies. And that has driven researchers worldwide to consider ways of 3D printing dirt, or “regolith” in space terms, in structural patterns.

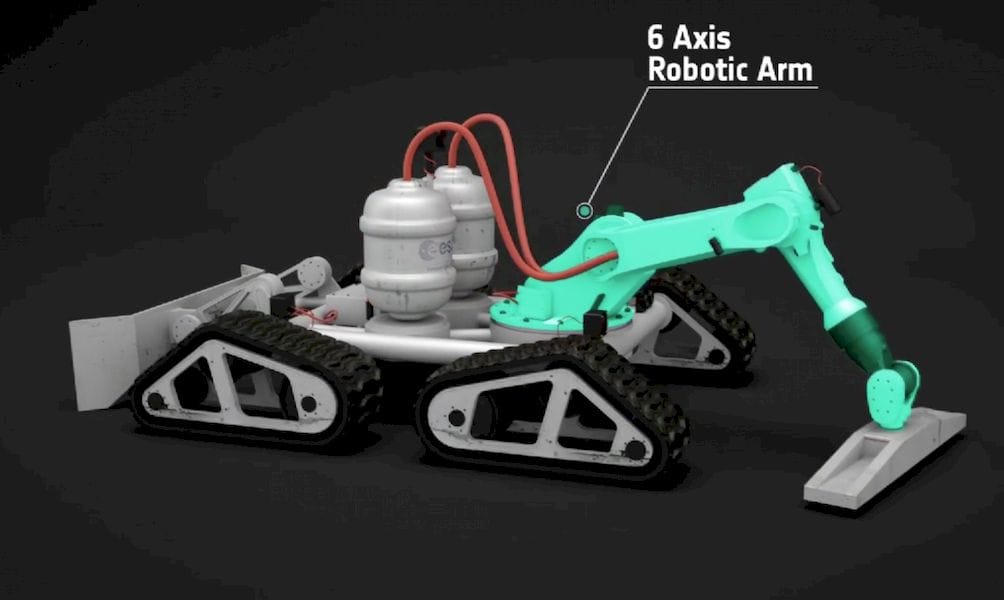

De Kestelier shows that the 3D printer that will do this is actually quite small, the size of a desktop 3D printer or smaller. This doesn’t jive with my assumption that a 3D printer printing a building should be the size of the building – or at least quite large.

No, it’s a different idea: the smaller machine can print smaller sections of the structure and then using its mobility, relocate to another section and perform printing a layer. It’s this “section-based” 3D printing approach that interests me.

It seems that in this configuration, the process trades time for machine size: the smaller machine can do the job, but will simply take longer as it moves around the structure. Normally we don’t think about 3D printing in this way because in almost all cases the entire print fits within the 3D printer.

In a way, this is like using a single 3D printer to print a series of parts to be assembled serially. Except they are assembled as they printed.

The small size of the 3D printer is also very amenable to the large transport costs to the Moon. Thus, it seems that 3D printers in space will be small, at least at the beginning.

There’s another interesting aspect, when De Kestelier talks about how similar 3D structure printing will occur on Mars. The difference there will be the implication of autonomous work due to the tremendous distance between Earth and Mars.

For this, De Kestelier proposes using not one, but a swarm of dozens, or perhaps hundreds of small mobile 3D printers, perhaps with specialized roles. This “3D printer army” will swarm over the Martian surface to gather up regolith and work together to rapidly produce a structure in parallel. The multiple number of machines will greatly assist the reliability of the project, as all devices will be multiply redundant.

These seem to be very intelligent ideas to address the needs of 3D printing in off-Earth environments. However, is there a lesson here for 3D printing on Earth?

Would small and mobile 3D printers be just as capable of printing a large building? Could a swarm of small mobile 3D printers be used to speed up a 3D printed building project?

I think this is certainly an option that should be investigated. After all, if it works on Mars, it should work here, too.

Via YouTube