3D software producer Dassault Systemes made several announcements today that will have some effect on the world of 3D printing.

The company made five key announcements, most of which dealt with improvements to their prime software system, Solidworks, and its ecosystem. Let’s review them now.

First, they announced a new collaboration feature, 3DEXPERIENCE Social Collaboration Services. It seems to be a way for participants in a design project to work together online to share comments, files, images, and other material in a completely coordinated and integrated manner. This should prove quite useful as the discussions and threads could be used as the knowledge trail long after the project completes. The Solidworks CEO described it as a kind “Google Drive that knows about Solidworks”.

They also announce what seems to be an integrated project management system, 3DEXPERIENCE PLM Services, that, when accompanied by the collaboration feature, should permit work to be dispatched easily among participants. A product designer feature should also make generation of highly complex parts much more automated.

That’s all good stuff, but there was more.

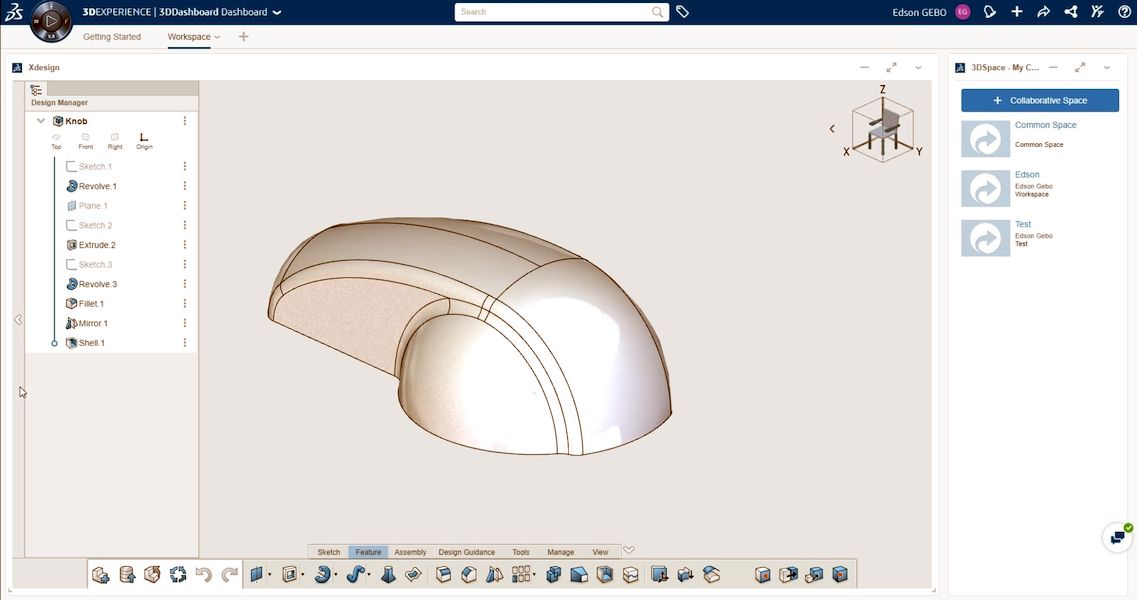

The new xDesign system is a way to access and use Solidworks from a browser. This will immediately enable use of the otherwise heavy 3D CAD system on mobile devices, such as a tablet. Thus, instead of lugging your bulky super-laptop to the customer site, you need only bring your iPad Mini. There are some implications to this for other CAD systems, in particular Onshape, but we’ll talk about that in another post.

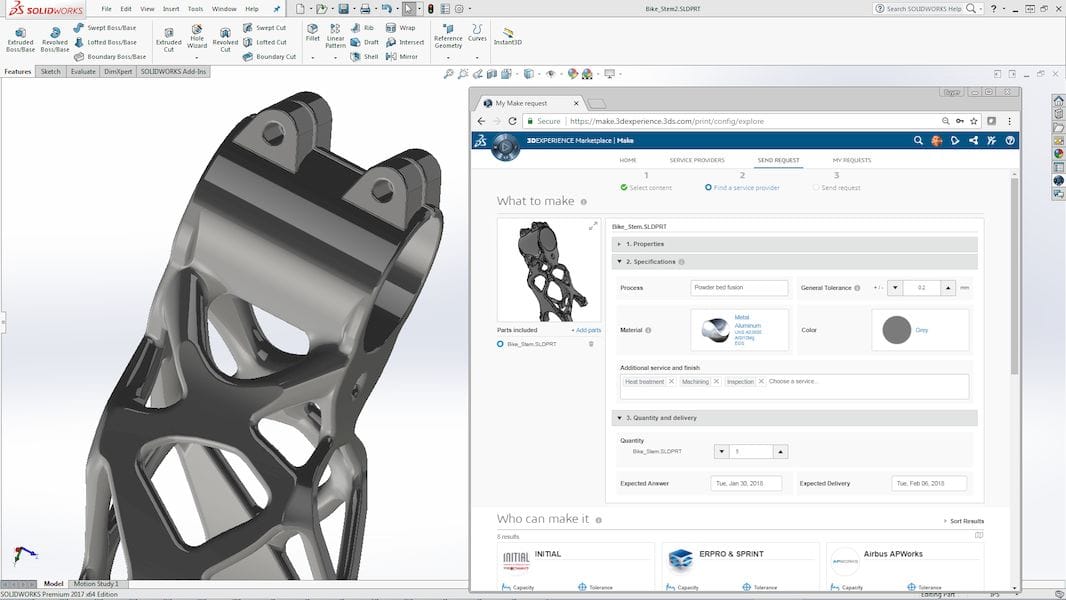

Finally, they announced the awkwardly named “3DEXPERIENCE Marketplace Make”. This is a new system that connects Solidworks users directly with manufacturers who can produce the newly designed parts.

It’s not merely a referral service; “Make” (if I am allowed to shorten the service name) provides a variety of features to interact with the providers throughout the design process. In other words, you don’t just “throw it over the wall” at the makers, instead you communicate with them iteratively to refine the design to the end goal.

So far Solidworks has attracted 50 providers totalling 500 making machines of various types to the service. I suspect with Solidworks’ very large customer base they will shortly attract many more. However, it seems that you must qualify to participate and present appropriate experience and credentials to attract buyers.

If this sounds a lot like a community maker network, it should because it is. This announcement, I think, directly affects several existing making and 3D print networks, such as MAKExyz and 3D Hubs. I’ll provide some additional thoughts on this in the near future.

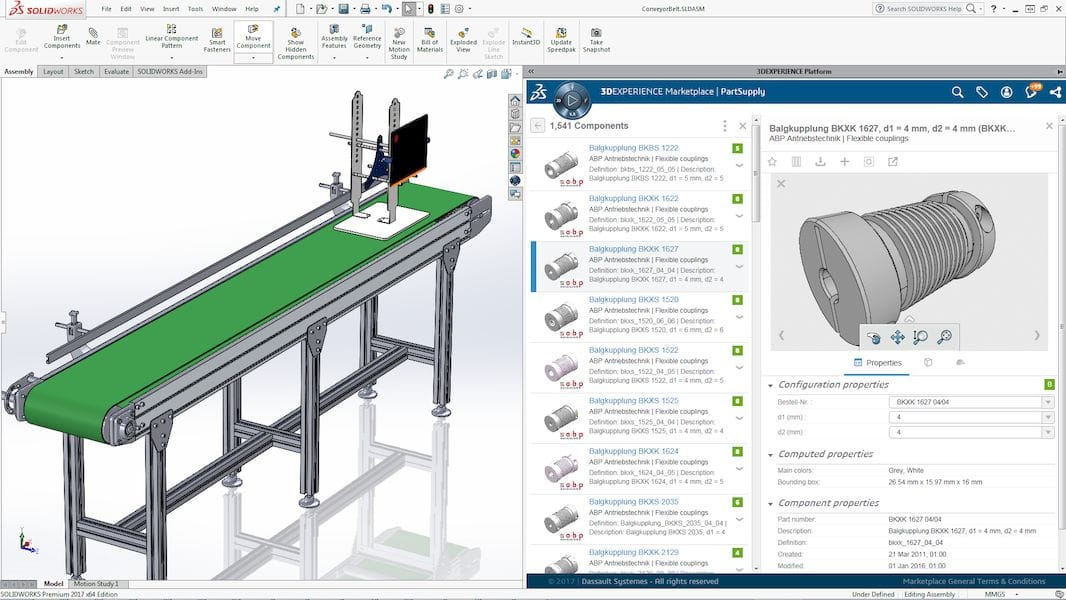

There’s another very interesting feature they call “Part Supply”. This allows vendors of components to integrate their product catalog directly into the Solidworks ecosystem, where designers can browse through apparently “billions” of standard parts and directly insert them into an ongoing design. This could vastly simply some types of 3D product design.

But it also is a very strong attraction for parts suppliers to get their catalogs integrated. Those who are not integrated will not get the orders they would from Solidworks users.

In all, these announcements from Solidworks could be described in a single word: “Sticky”. These compelling features will certainly draw many more participants into Solidworks’ ecosystem, and it would be difficult to leave it once you’re in.

While they may be providing complex 3D CAD solutions to the largest number of designers, they aim to keep it that way through these new features. Think about it: once you’ve completed a project using the collaboration and project tools, you probably want to maintain that record, if only for legal reasons. If you’re a manufacturing shop, why wouldn’t you want to plug into the Make system?

And if they are doing that, then why wouldn’t users want to continue to use Solidworks?

I’ll have some additional details and thoughts when I get some more data.

Via Solidworks