There are plenty of startup companies pursuing unusual 3D metal printing processes, and one of them is Los Angeles-based 3DEO.

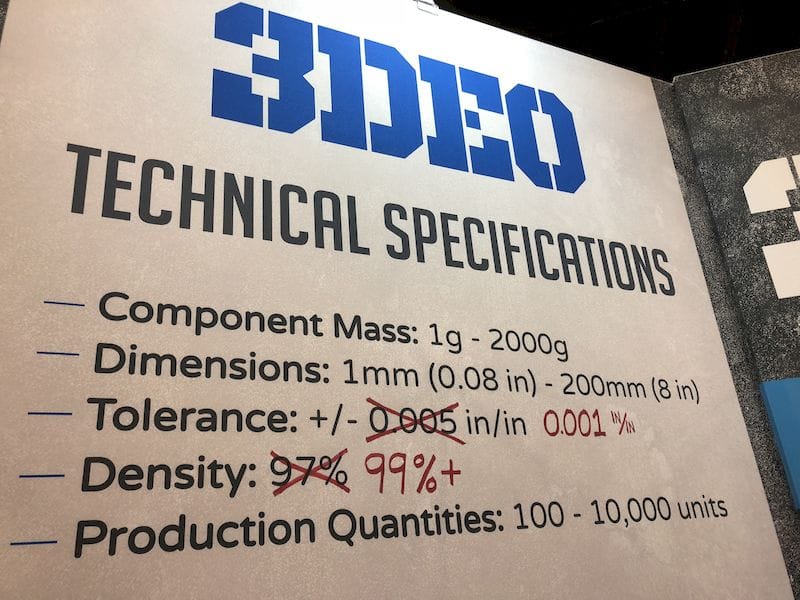

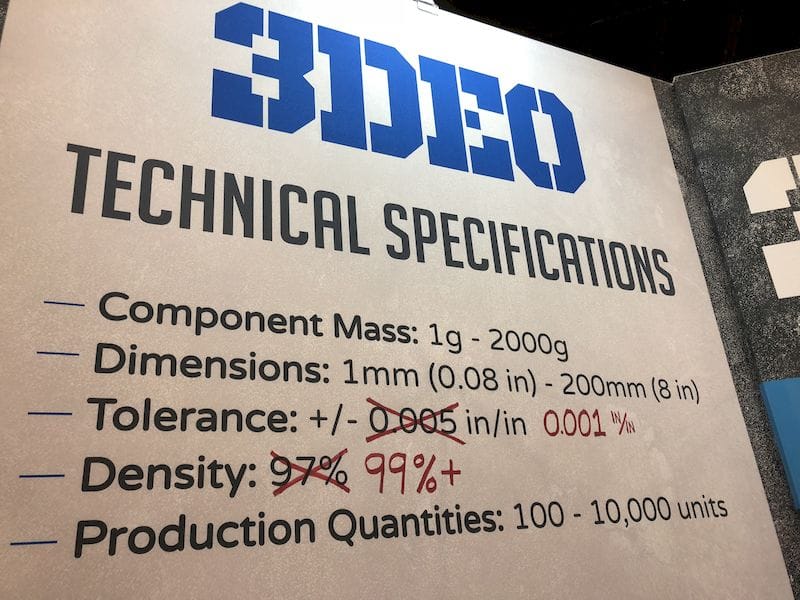

The company has developed an unusual and inexpensive process for producing finely detailed metal 3D prints. Their process involves a two-step binder jet process that produces green part for subsequent sintering in a furnace. But the process also involves integrating a CNC mill to smooth the edges of the print at each layer, creating parts that are essentially ready for use when complete.

They say this marriage of 3D printing and CNC milling produces “clean parts”.

Another very important advantage to their process is that it uses standard metal injection molding materials (MIM), which are both inexpensive and commonly available everywhere in a wide variety of alloys.

As such, 3DEO believes their prime competitors will be MIM processes, not 3D printer options.

3DEO says their process, when completely automated, will be “fully competitive” with traditional MIM operations, suggesting they are very confident of the future low operational price of their system.

But it seems that their focus is on the smaller objects. Here we see a larger part with a number of smaller parts poured inside.

The proportion from 3DEO was that while you could sell the larger part for a reasonable price, you would be far more profitable selling all those smaller parts inside – and they can be made in more or less the same time and materials as the larger part. Thus they hope to focus on smaller parts, at least initially.

We asked them whether their process is certifiable, as is required by several current industrial users of 3D metal printing technologies: aerospace, medical and automotive. 3DEO is not currently concerned with obtaining certifications, as their initial market will be smaller companies performing general manufacturing, not specialized applications requiring regulatory certifications.

However, I suspect they could eventually obtain the necessary certifications if and when required. The key here is that 3DEO is a small startup company that must take practical steps forward that are each achievable. It is not really feasible for them to immediately attempt to compete with the big guys who have entrenched relationships with the aforementioned certified industries.

Meanwhile, they are obtaining ISO 9001 certifications for their own internal operations, which is something that may assist in their future sales.

It seems there are going to be a multitude of inexpensive 3D metal printing processes available to industry within the next year or so, and 3DEO should be one of them.

Via 3DEO

1 comment

Comments are closed.