I had a thought about how the integration of 3D printing into manufacturing may change how we think about products.

Historically most products we use have been mass manufactured. They have come from factories with a series of build steps that involve potentially complex molds or dies, assembly of integrated parts, finishing steps and much more. The result is a product that is essentially identical to those that came before and come after.

The cost of setting up such a manufacturing facility is high, but is offset by the sales of potentially millions of products. Each sale contributes a small amount towards paying off the initial set up.

The goal is to sell as many units as possible with the existing manufacturing set up.

At the other end, consumers receive the identical products and make good use of them. They believe others who have the “same” product actually have the identical object – and they do in almost every case.

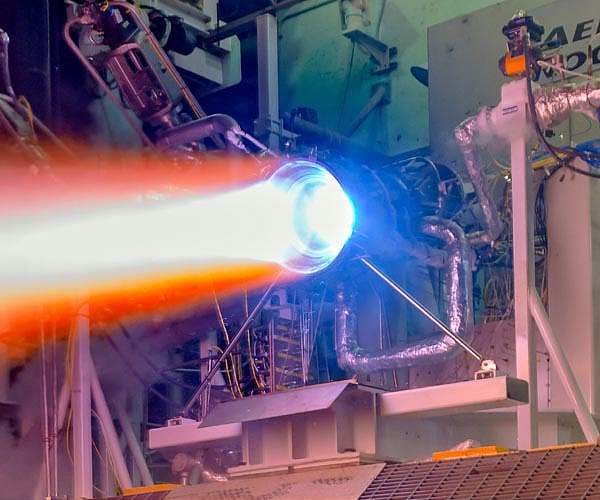

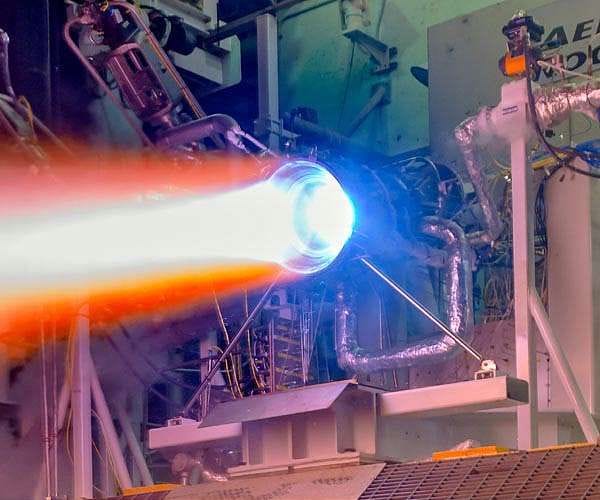

But then I read a story about how Aerojet Rocketdyne has been testing new versions of their RL10 rocket engine. It seems the company has been using 3D metal printing to improve the performance of the engine. Specifically it seems that they are “re-generatively cooled”, likely through the incorporation of tiny venting systems enabled by 3D printing.

That’s great news for that company, as they can make their future flights better.

But then I thought: as they deliver products (rockets in this case), they may be slightly different as improvements are incorporated over each launch or even sets of launches.

What happens when this practice becomes more widespread?

What happens when factories include large numbers of 3D printers that can be directed to produce different styles of parts almost at a whim without mucking up much of the production line? What happens when a design change can be instantly cascaded through all the parts being manufactured?

We end up with products that are somewhat different than the previous ones. And tomorrow’s products might be again slightly different.

Consumers of such products may have to have a slightly different viewpoint of their item: it’s a version at a point in time, rather than “one of the many of this version”. People may come to expect that it’s a given that their product is going to be different than others.

I don’t know what that means. Will people feel “bad” that they didn’t get the current, best product tomorrow? Will they feel compelled to renew/buy items more frequently because of this? Or will they give up and not buy as frequently because there’s no way to “catch up”?

I’m not sure the marketeers have thought this aspect through, and when the day comes when products evolve constantly there could be some surprises.

Via SpaceDaily