Virtually all major resin-powered 3D printers today can use the manufacturer’s materials.

When you purchase a resin 3D printer, you’ll usually be directed to an online store or resellers who allow purchases of resin cartridges made by the 3D printer manufacturer.

This is both a good and a bad thing.

While it’s obviously good for the manufacturers because it provides a steady stream of post-sale revenue, it is also good for the user. Why? Because the manufacturer can control the specific chemistry of the resin and thus be able to very finely tune their software to ensure reliable, high quality 3D prints.

That’s a critical factor for many users, who likely bought the more expensive resin machine over less expensive filament devices simply for the ability to get better quality prints.

But it can be a bad thing for users in that the manufacturer may consider the situation monopolistic and thus raise prices precipitously over alternative suppliers.

This can be considerable: we were told by one of the five worldwide manufacturers of photopolymer resin (who supply many 3D printer companies with white labeled resin for their own packaging) that the actual cost of resin can be marked up as much as 20X by 3D printer manufacturers.

Thus it can sometimes be very important to have a machine that permits the use of third party resin, who can not only provide materials at lower prices, but also types of materials unavailable from the 3D printer manufacturer.

For some time you’d find only two types of resin 3D printers: those that permitted ONLY the use of manufacturer’s materials, enforced by RFID chips in the cartridges; Or “open materials” machines that had no affinity to any particular resin.

This led to only two scenarios:

You pay a lot and get great prints, but have little choice

You pay little but struggle to find the right print parameters to optimize print quality

My thinking is that many people actually find themselves in both situations from time to time.

Sometimes the print just has to work, perhaps for a very important client or a pending deadline. In that scenario you might pay more for the privilege of getting a guaranteed good result.

But at other times you may want to print low priority items, or perhaps experiment with different materials on a project.

This dual behavior pattern among users doesn’t really fit into the traditional resin 3D printer models.

But that could be changing; at least one company, Formlabs, seems to have recognized this phenomenon and created a regime that can account for both scenarios in a single machine.

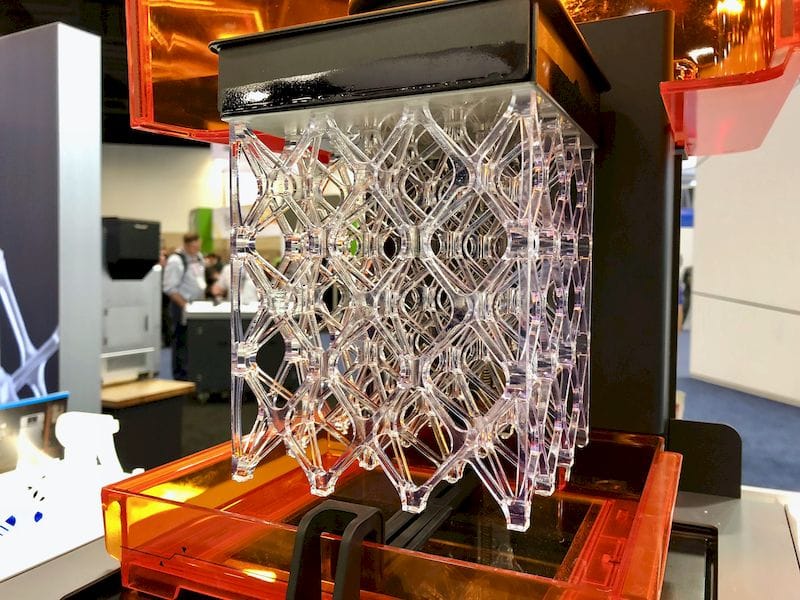

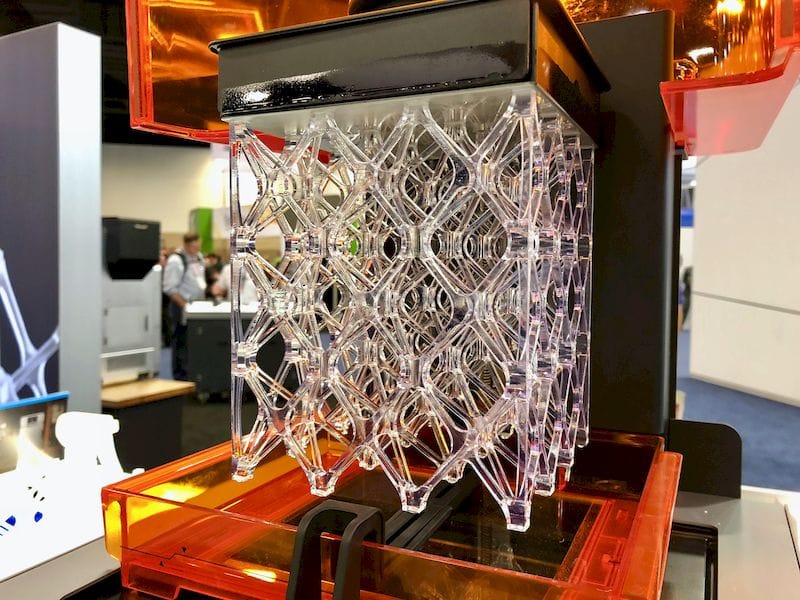

On their most recent resin 3D printer, the Form 2, they offer an experimental mode that must be explicitly turned on. By default the machine is in a mode that requires use of their own materials.

I think this is an ideal approach, because it permits their users to choose the mode they’d like to use. I expect many of their Form 2 users may simply never turn on the experimental mode and are quite happy to pay for terrific, reliable prints. But they will also have some customers that occasionally do turn on experimental mode for various reasons.

However, someone who would always have experimental mode on might have chosen a less expensive, permanently open materials device.

I’m wondering how many resin 3D printer buyers consider this before purchasing a machine?