I’m watching an unusual video of a strange concept: fixing potholes with 3D printers on board drones.

I know that drones are being increasingly used for a wide variety of uses, but this one seems a bit curious to me.

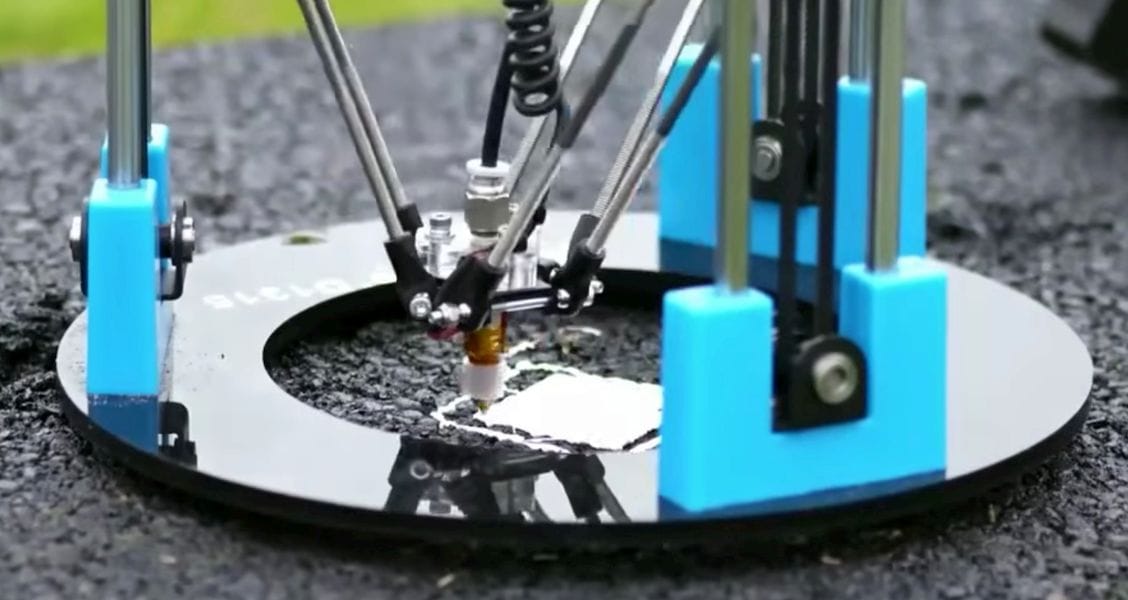

The concept (and it is literally a concept, as per the researchers from the University of Leeds in the video) is to mount a delta-style 3D printer on the bottom of a six-rotor large drone. The drone then flies along a roadway and somehow detects the presence of potholes, perhaps through remote 3D scanning.

Once a pothole is detected, the drone positions itself over the hole and thus places the 3D printer in position. A 3D scanner then captures the shape of the hole and allows the 3D printer to fill the hole with an appropriate mix of tar, rock, etc to “1mm accuracy”.

There are so many problems with this I am not sure where to start.

While this may or may not be a legitimate project at a very early stage of development, let’s make a list of questions that should be considered:

Typical potholes are often far larger than the build volume of a 3D printer. How is this handled? Does the drone reposition the printer over a new section of the hole to fill in more? How accurate could that repositioning be?

In the video, the 3D printer is shown printing thin plastic extrusions, and not the appropriate material for properly sealing roads. It’s filling a hole which requires almost no fine details. There is no requirement for such a tiny nozzle, which would simply increase the print duration for no benefit.

How would bulk material, like rock and tar, be delivered? I think the issues of simply 3D printing that stuff at all would be a challenge, and moving it around by drone would be far simpler – except for the weight.

I suspect the drone would have to be followed by a truck with supplies that would be used constantly as the drone’s maximum payload would likely be far, far less than the weight of fill material for even a single reasonably-sized pothole.

Potholes are usually wide and shallow. There is absolutely no need for a delta-style 3D printer to do this work, as they are designed for tall and thin objects. What you would want is a wide-format printer. The delta printer shown is perhaps the worst possible choice for a 3D printer.

How is loose debris removed from the pothole before it is filled? Does the drone have capability for doing this?

How does the 3D scanner recognize loose material? What about material that’s not quite loose but is about to break? Does the system print on top of that and produce poor results?

How economical is this concept? How many holes can be filled per hour and at what cost? How does that compare to any other reasonable approach? This process cannot be faster than a burly workman with a shovelful of hot asphalt.

While I’m sure the 3D printer will produce a smooth top surface, how is the material compacted to ensure it is fully engaged with the bottom of the pothole? If this is not done, then vehicles will surely knock the filling loose.

I’ll stop there.

I think this concept is entirely wrong, as it cannot possibly work effectively for at least a dozen reasons. This seems to be an incorrect application of 3D printing, and could even be a hoax.

If you really wanted to do something like this, I’d recommend having a drone hold a sprayer hose in front of a slowly moving supply truck. The drone might be able to find smaller cracks and holes and spray them shut quickly. The supply truck would carry a day’s weight of material, and the drone need only carry a hose-full at a time. The supply truck could also press the spray flat after application.

Meanwhile, enjoy the video.

Via YouTube