A student competition saw a demonstration of a 3D printed internal combustion engine.

According to Zoltán Dudás, Head of metal AM at Audi Hungaria Zrt, the system was recently tested at a public event. The engine was produced by Audi Hungaria, a subsidiary of Audi that produces many major components for Audi vehicles of all types.

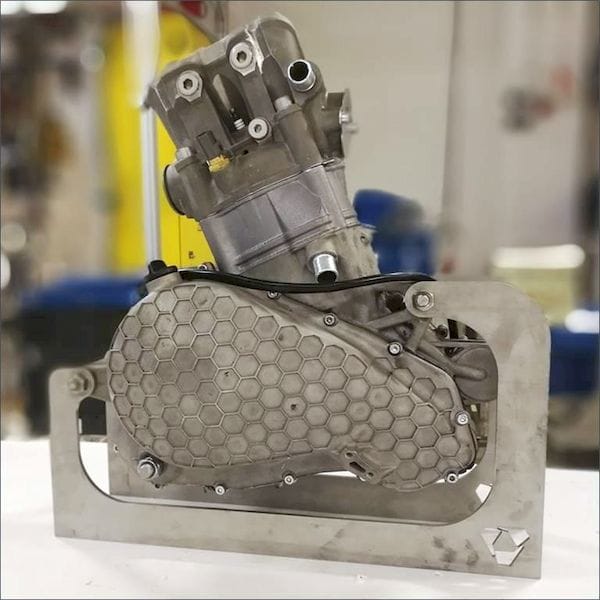

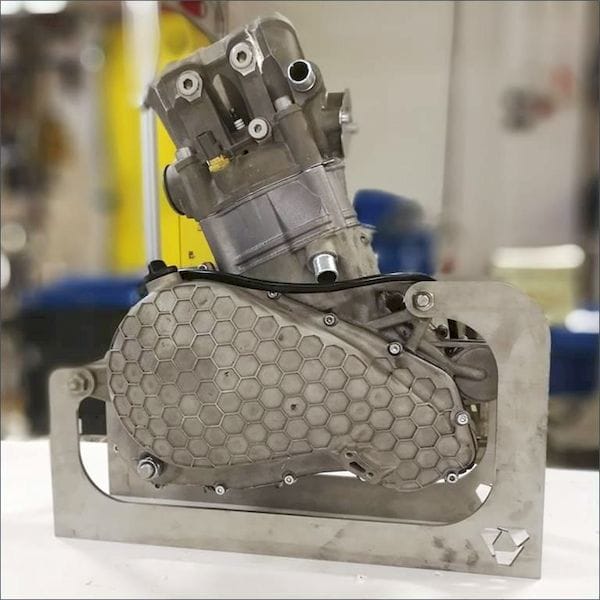

There’s not a lot of detail here, but from the image it appears to be a single-cylinder mechanism, as one would likely build given it is apparently the first time this has been attempted. But with so much 3D metal printing technology now available, this was inevitable.

What’s of most interest to me is the design of the engine. You’ll note the cover plate in the foreground includes a hex pattern embossed on the curvy surface. I’m wondering if this could be the start of some very interesting engine designs.

This phenomenon has happened in other industries, where 3D printing technology has been adopted and then leveraged. It makes little sense to simply 3D print the same designs that you could already produce using conventional making technologies, although it’s technically possible to do so.

Instead the capability of 3D printing to make so-called “impossible objects” should be leveraged with imagination to create new designs not previously achievable. The aerospace industry in particular has made significant strides towards standardizing on these unusual designs.

Of course, that industry has an advantage: low-weight parts are significantly valuable, as they directly correlate to lower fuel costs in the end products, which is highly attractive to clients. Even better, aerospace parts already are quite expensive, so a 3D printed version’s price won’t be noticed.

So it works for the aerospace industry.

But could it for the automotive industry?

So far we’ve seen plenty of examples of automotive companies producing less critical components using 3D printing, such as dashboard prototypes, customized decorations, steering wheel centers, etc. But the “guts” of the vehicles has essentially remained the same.

But perhaps those guts may begin to change if it is possible to design radically new internal combustion engines by leveraging 3D print technologies?

The visible components on the Audi Hungaria example appear to be mostly conventional in design appearance, but what if they weren’t? What if, for example, they were significantly lighter? Engines make up a notable portion of the weight of a vehicle, and fuel efficiency might increase if that weight were decreased through 3D printing.

Showing that it is indeed possible to 3D print an internal combustion engine is a big step forward, as it demonstrates that it is feasible to others. And those others will gradually explore new styles of designs in order to create the best possible engines.

However, as has been the case in other industries, it will most likely take several years for designers to get their heads around the concepts and truly leverage 3D printing. It’s very hard to shake years of training and practice, but in the end it could be a very good thing.

Via LinkedIn