![Making polymers more efficiently [Source: ACS]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a96e2660a.jpg)

I’m reading a fascinating paper describing how one could make new polymers on the fly.

The chemistry of polymers is complex and much like a jigsaw puzzle, with different monomers being combined to create polymers with differing properties. Normally this is done through considerable research and experimentation, arriving at a method of reliably producing a particular material.

Some of these polymers are used in 3D printing, and 3D printer operators would find them quite familiar: ABS, PLA and many others.

But one of the biggest issues with 3D printing today is the relative lack of choice of materials. While there are thousands of engineering materials known to exist today with an enormous range of properties, few of these are actually available for 3D printing.

Chemical companies have only now turned their attention to 3D printing and have begun to design unique materials specifically designed for 3D printing purposes. But it will be a long time before there is a suitable set of 3D printing materials available.

However, it seems that now that journey may be sped up somewhat with researchers developing a method of making new polymers “on demand”. Researchers from Cornell University explain:

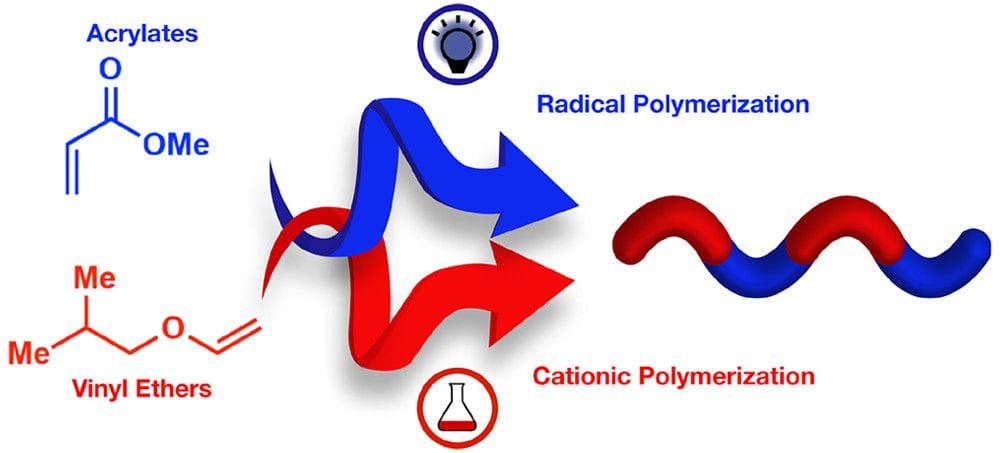

We developed a cationic polymerization where polymer chain growth is controlled by a chemical stimulus and paired it with a compatible photocontrolled radical polymerization. By alternating the application of the chemical and photochemical stimuli the incorporation of vinyl ethers and acrylates could be dictated by switching between cationic and radical polymerization mechanisms, respectively. This enables the synthesis of multiblock copolymers where each block length is governed by the amount of time a stimulus is applied, and the quantity of blocks is determined by the number of times the two stimuli are toggled.

This new method allows on demand control over polymer structure with external influences and highlights the potential for using stimuli-controlled polymerizations to access novel materials.

It may be that chemical companies, if permitted to use this technology, might be able to develop suitable 3D printing materials much more quickly. That’s good news for 3D print operators, although it may be several years yet before we see a large increase in available materials.

One more thought I had about this research was the possibility of integrating it directly into a 3D printer. If one did so, it might be possible to create different polymers within the machine itself, on demand to meet the requirements of printing, minute by minute.

And it’s probably a fanciful notion, because there would be all kinds of challenges in doing so, such as the amount of time and minimum volume required to execute the process. It would also be subject to some constraints and would likely be able to produce only a smaller set of materials.

But thinking about this leads one to begin to glimpse a future world where you may find machines that could print far more useful objects.

Via ACS