![[Source: Tech Cast LLC ]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a1c20ecfc.png)

Charles Goulding and Tyler Gianchetta of R&D Tax Savers explore pump and impeller applications for industrial 3D printing.

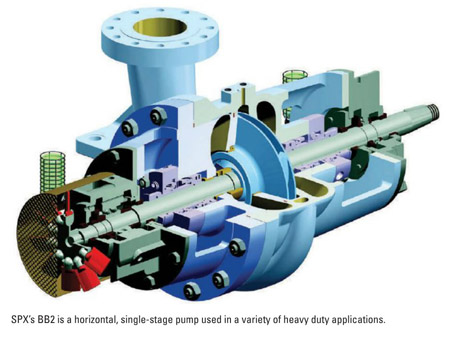

The impact of 3D printing has been well-documented across a multitude of industries, especially in relation to manufacturing, for a variety of different products and processes. The technology has now added yet another key cog of manufacturing to its already extensive list of applications – pumps and impellers.

The Research & Development Tax Credit

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

-

Must be technological in nature

-

Must be a component of the taxpayers business

-

Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

-

Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include U.S. employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, U.S. contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum tax for companies with revenue below $50MM and for the first time, pre-profitable and pre-revenue startup businesses can obtain up to $250,000 per year in payroll taxes and cash rebates.

ExOne

ExOne has long staked its claim as a global leader in digital part materialization, and features nearly 100 full-time employees as well as a dedicated machine build center for metal 3D printing and a lab for research and development. Headquartered just outside of Pittsburgh, Pennsylvania, the company has been at the forefront of several innovations for pump applications, including improved hydraulic balancing of impeller casting and faster turnaround times for one-off castings and 3D printed metal components. Concurrent iterations that previously would take months to conduct can now be achieved in a matter of weeks, or sometimes even less.

ExOne’s digital processes help customers in the pump manufacturing industry to produce castings for prototyping, replacement impellers, volute shapes and rotating parts. They have implemented 3D printing as part of their already extensive repertoire of services to manufacture complete mold packages and even integrate a “hybrid” approach to print just the cores.

ExOne has integrated additive manufacturing processes in the creation of their wide variety of molds and cores, and as a result, they have been able to substantially reduce the time and cost required to produce casting in a quick and efficient manner. Where traditional pattern manufacturing methods would take months to deliver mold packages to the found, 3D printing methodologies are able to execute this process in a matter of days.

Through their research, ExOne has also determined that additive manufacturing is unquestionably the ideal application for the reverse engineering of legacy pump components. This is because along with the benefits of saving time and material costs, 3D printing also mitigates the necessity of physical warehouse space for patterns because the data files can be stored on a hard drive. Additionally, the parts themselves have displayed other benefits such as improved impeller core accuracy, superior blade registration, better hydraulic performance, and increased ease of dynamic balance.

Tech Cast LLC

Designing pump impellers that can deliver a consistent high performance quality can often be very challenging due to the high flow velocities and volumes, as well as the multi-component nature, of the fluids. Therefore, standard analytical tools can only provide a rough estimate of pump performance, whereas the actual performance can only be determined through experimentation, which consequently leads to an extensive iterative process of creating a design, building the impeller, testing its performance, modifying the design, and repeating until the optimal design is reached.

Unfortunately, utilizing this method of optimizing performance is incredibly taxing in terms of both time and expenses, often containing high tooling costs and long lead times, especially for large impellers such as those that Tech Cast LLC manufactures. The tools themselves often necessitate the construction of either soluble or ceramic cores to create the internal flowpaths, thus requiring two separate tools to be built. Due to the impracticality of repeatedly modifying or rebuilding tooling to evaluate design changes, many pump manufacturers do not undergo the additional iterations to achieve the best performance, instead opting to reduce their cost and settle for “acceptable” performance.

![[Source: Tech Cast LLC ]](https://fabbaloo.com/wp-content/uploads/2020/05/Pumps-Image2_img_5eb0a1c2817ab.png)

However, Tech Cast has embraced the mentality that “acceptable” is simply not good enough. They have recently pioneered a process to drastically reduce the amount of time and cost per iteration. This allows pump manufacturers to cycle through multiple iterations in less time than they could previously go through for just a single casting in the past, all while shaving the cost of production as well. This unrelenting push for innovation is a significant reason why Tech Cast has been a perennial leading supplier of high-quality investment castings for years, and they have continued to explore potential strategies to refine their products and processes even further.

Tech Cast utilizes SLA QuickCast 3D printed patterns to alleviate the need to create or modify separate tooling for each individual iteration. Using QuickCast patterns, castings can be created without the lengthy process of creating tooling to produce wax patterns, thus shortening the design evaluation process to a matter of days instead of months. QuickCast features an array of resin-based patterns that are hollow with unique internal honeycomb structures, which allow the patterns to collapse internally as they expand with temperature. It also helps to minimize the amount of material in the pattern, yielding a nearly ash-less burn that enables the creation of the casts to be expedited significantly.

The advent of this new methodology also substantially reduces the cost of the overall process, as the cost of QuickCast patterns is generally a fraction of conventional tooling costs, and they are available in less than a week, which means that fully machined impellers are readily available within a mere three weeks.

![This double suction impeller featuring a 15” diameter was the subject of a study conducted by Tech Cast and 3D Systems to better understand and quantify the advantages of their process when compared to the standard iterative procedure. [Source: 3D Systems ]](https://fabbaloo.com/wp-content/uploads/2020/05/Pumps-Image3_img_5eb0a1c2de84d.png)

The first step for both the conventional process and the Tech Cast process is to create a CAD model of the casting, which is required in each case and typically takes a week. Once the machined impeller is defined, the foundry must then scale the impeller up to compensate for the metal shrinkage in casting, and subsequently add machine stock and gates.

In the conventional process, the file is then sent to a tool shop where a tool is created in which wax patterns will be molded. Conversely, in the Tech Cast process, the model is sent to 3D Systems where a QuickCast pattern is created. The cost of the pattern in the latter case tends to be around $3,100 and requires one week to complete. By comparison, the tooling cost for the conventional process is approximately $40,000 and requires 7-9 weeks to create.

![This table directly compares the Tech Cast process to the conventional process for the double suction impeller shown above. [Source: 3D Systems ]](https://fabbaloo.com/wp-content/uploads/2020/05/Pumps-Image5_img_5eb0a1c338a7d.png)

As the study shows, the Tech Cast process provides an impeller in less than half the time and less than 10% of the cost compared to the conventional process, as well as alleviating an additional $81 in labor content. In addition to these benefits, it is also substantially easier to integrate design changes if the first cast is not acceptable. For the conventional process, the entire tool must be modified to incorporate the change, which contributes additional time and cost. The amount of time and expenses varies depending on the extent of the change, but even a relatively minor change takes nearly two weeks, and an average change would reasonably take 15% of the tooling cost. However, in the Tech Cast process, making this second impeller requires significantly less time and expenses, as the updated model will be utilized to create a new QuickCast pattern which will then be cast.

![The above table displays the comparison between the two methods at the time the second impeller is completed. [Source: 3D Systems ]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a1c37dba8.png)

The data blatantly demonstrates the benefits of integrating 3D printing processes into the pump and impeller manufacturing procedures. The results are only amplified as further subsequent iterations are conducted.

In addition to the overall efficiency and cost-related benefits, the Tech Cast process allows castings to be built even while a tool is being constructed. This allows manufacturers to build field test units and initial production pumps before the tool is available, which helps get to market even faster.

Conclusion

Tech Cast and ExOne have been leading a revolution of innovation in the manufacturing of pumps and impeller castings. They have both been at the forefront of 3D printing initiatives in the industry, and have experienced significant benefits in terms of increased output efficiency and reduced cost, as well as the ability to manufacture designs that were previously impossible through conventional means.