![Shape-memory polymers can help design adaptive components [Source: SUTD]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09e489ba6c.jpg)

Some very interesting research shows how shape-memory polymers could be used in functional 3D printing designs.

Researchers at the Singapore University of Technology and Design (SUTD) have developed a way to incorporate shape-memory polymers into a robotic arm actuator, the “hand” of the arm, so to speak.

The challenge robot arms typically face involves the ability to engage with a wide variety of materials. In some cases, the actuator must be extremely rigid and strong if it is to lift a larger item and move it about. On the other hand, there are times when a gentler touch is required. In some ways these are the same issues facing humans when using our very versatile hands.

When 3D printing an actuator these factors must be accounted for, leading to some unusual designs. By simply 3D printing a generic actuator in a single material you really have to choose between having a strong and rigid actuator, a soft and gentle actuator, or a compromise that meets neither set of requirements. So the traditional approaches to 3D print design don’t really work well in this situation.

Another approach might be to use a multi-material design, in which there are hard and soft components. That may work in some situations, but not all.

Another approach could be to design a metamaterial actuator, one that includes sophisticated structures that bend and twist under load to provide additional strength when required. That’s complex, and in fact not what the SUTD researchers attempted.

No, in fact they used something completely different: shape-memory polymers. These are polymers that “remember” their original shape. They can be heated to relax their shape — and become softer. But after removing the heat they will regain their original shape and become rigid.

![Designing a robotic arm actuator with shape-memory polymers [Source: SUTD]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09e49010b7.jpg)

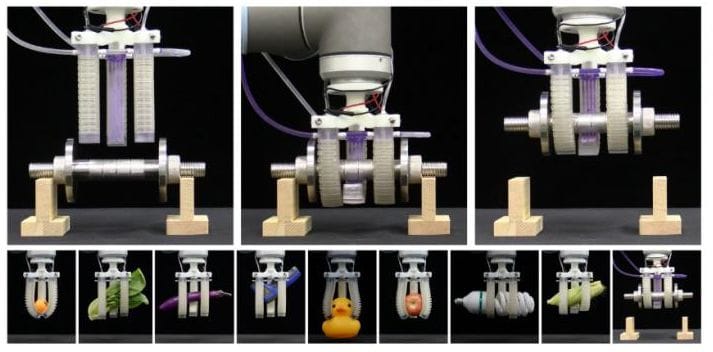

The researchers’ design is quite interesting, as seen here. They used a conductive ink embedded within the shape-memory polymer to induce heat on demand. When energized, these “wires” warm up and relax the shape.

They say that the reverse cycle, going from soft to rigid, takes only 32 seconds.

This enables the production of a robotic arm actuator that can, on demand, become rigid within a minute to take on different tasks. This is quite important if a robotic arm is used in an environment where its sequence must deal with a number of different components. Instead of changing out the actuator, this new design allows the robotic arm to literally change the function of its own actuators as required.

In the image at top you can see the actuator being used to grasp an extremely wide variety of objects, each having very different access requirements, including a fragile CFL bulb, a metal rod component, a rubber duck and what appears to be Bok Choi.

Imagine attempting to design an actuator for each of those — or instead designing just one that can adapt on demand.

That’s a fantastic approach that I think could be used for great effect in 3D printing, not only for robotic arm actuators, but I suspect many other applications we must explore to find out.

Via Eureka Alert

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.