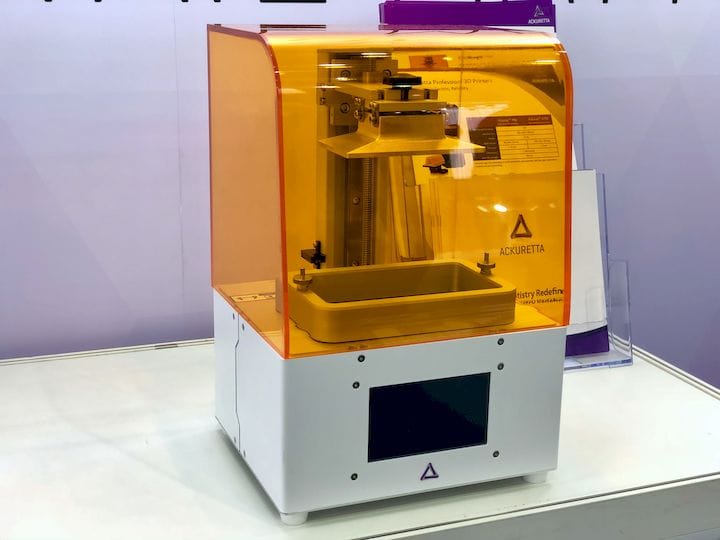

![The new Ackuretta FreeShape 120 high resolution 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09d85201c9.jpg)

Ackuretta has released a new 3D printer for the dental and jewelry markets, the FreeShape 120.

The Taiwan-based company has been producing high-resolution 3D printers for several years, and now announces the FreeShape 120.

Like most dental 3D printers, this is a resin-based device that achieves high resolution through a photopolymer fusion process. Unlike most other resin 3D printers that use lasers or DLP projectors as their light engine, the FreeShape 120 uses a simple LCD panel directly under the resin tank.

![Inside the Ackuretta FreeShape 120 resin 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09d856d30e.jpg)

This has the advantage of forming precisely accurate voxels across the entire layer surface. Lasers and DLP light engines hit the resin at angles depending on their distance from the center, and thus the solidified voxels are slightly non-round.

This is not the case with the Ackuretta approach, where each voxel is formed by an adjacent LCD pixel, making them of equal dimensions regardless of their location on the print layer. Perhaps this is why they named the company “Ackuretta”?

Like most dental 3D printers, the build volume is relatively small when compared to other types of 3D printers, at only 120 x 68 x 140 mm. But that is more than sufficient for virtually any conceivable dental or jewelry object.

The resolution is excellent, as it carries forward from the LCD panel: voxels are only 0.047mm wide in the XY dimension, and layers can be between 0.025 and 0.100mm.

![Some of the 3D printer resins offered by Ackuretta [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09d85b6d3e.jpg)

While Ackuretta supplies a range of powerful 3D printer resins tuned for their devices, the FreeShape 120 is also an “open materials” machine, meaning you can use any third party resin in the device if the Ackuretta offerings don’t suit your application or finances. However, you will have to discover the correct print parameters through experimentation. Meanwhile, their own materials are precisely tuned for achieving instant and excellent results.

The machine is equipped with not one, but two spare LCD panels. I’m wondering why this might be, and perhaps it could be that over time individual pixels on the LCD panels stick on (or off), causing slight imperfections in the prints.

It’s also equipped with two vat films. These are protective layers that engage the photopolymer during fusion. Over time they degrade and must be replaced, as their transparency degrades and light fusion becomes blurred. Here’s a short video showing how this is done, and it appears quite straightforward:

The print quality obtained from the FreeShape 120 is excellent, as you can see in this image. Note that this is a jewelry application, in which multiple items are printed within a single job run. This print shows how items are joined by sprues for subsequent casting into metal.

![Sample 3D print from the Ackuretta FreeShape 120 resin 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09d860601e.jpg)

The Ackuretta FreeShape 120 is targeted to beat the popular Formlabs Form 2, which is a bit higher priced than the FreeShape 120’s US$2,500 price tag. It could be the right machine for the price for many dental and jewelry operations.

Finally, Ackuretta sells the device through a worldwide network of resellers, and we’re told that they are currently seeking additional distributors, if you happen to be one looking for another product to sell.

Via Ackuretta

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.