![[Image: Aurora Labs]](https://fabbaloo.com/wp-content/uploads/2020/05/aurora_img_5eb09caca1507.png)

Aurora Labs this week took its next tangible step towards its ambitious goal to 3D print 1,000 kg of metal per day.

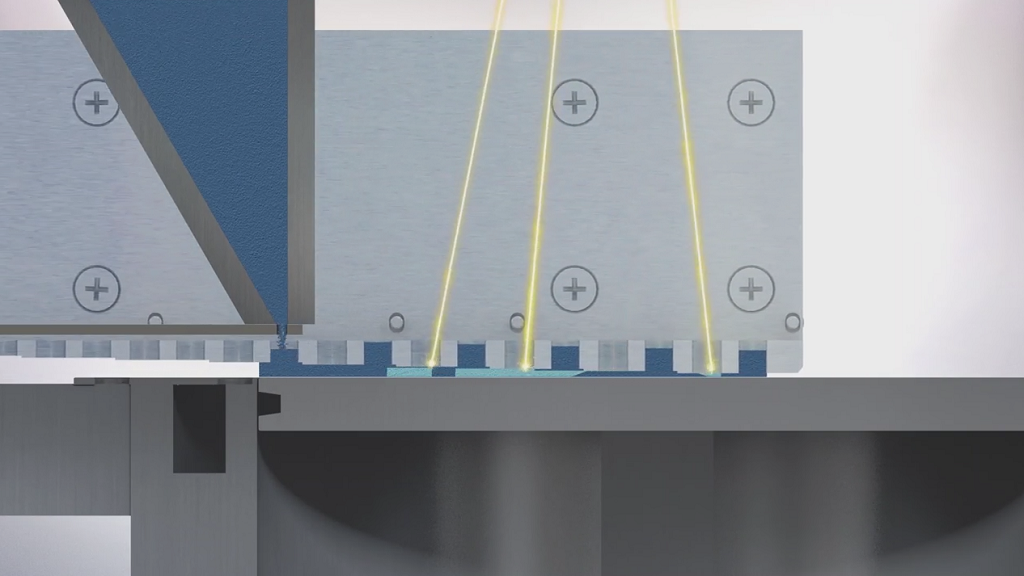

In November, the Australian company revealed the secret to its Multilevel Concurrent Printing (MCP) process for Rapid Manufacturing Technology (RMT). Rather than a layer-by-layer powder bed 3D printing approach, MCP does a layer-and-layer-and-layer-and-so-on approach with, as the name suggests, concurrent printing. The idea hinges on scalability, with the intent to create a system designed to fit the user’s needs (you can see a video here for a look at the process).

Laying down up to 100 layers in a single pass can fantastically speed up the process of creation — and for the industries and applications Aurora Labs is targeting, that speed is a remarkable asset.

So the company has been working to up that speed. This week they’ve finished testing to compare what’s currently possible via RMT as compared to the speed of other systems out there. Defining market speed as “the speed at which a comparable machine can print Titanium (CP-Ti)” and noting that market research reveals this current speed to be “81.7 g/hr or 1.96 kg per day,” Aurora Labs has demonstrated a new speed achievement:

Reaching 113 kg/day, RMT is now 3D printing at about 55x the current market speed.

Is that 1,000 kg/day? Clearly not, but that’s some fast progress made in a very brief timeframe already. In September, the company announced speeds of about 16 kg/day; in October, that had risen to 40 kg/day.

Aurora Labs’ Alpha machine, designed with one sub-unit, has been modified to include two sub-units connected together to scale up the system. Incorporating multiple such sub-units into a large-format unit will be the route to that 1,000 kg/day target.

When we spoke with the team at formnext, Managing Director David Budge explained of the approach to scalability:

“We only switched on the first machine a month ago; it will be a matter of weeks for the next. Scaling up the process is pretty straightforward. Think of computer servers: plug one in or multiple together, and it still acts as a single server.”

The company’s aggressive timeline was a key point of that conversation, and Budge was confident in his team’s ability to deliver. That confidence is proving out now with the February 13th success for this latest testing phase, focusing especially on scalability.

“Printing on multiple levels simultaneously at high speed is what we believe will ultimately allow us to print up to 1000kg in one day. A large portion of the groups that Aurora is currently in discussion with are interested in replaceable parts and the capability of replacing them directly using additive manufacturing or redesigning them using the advantages of 3D printing with superior materials to deliver a superior product at a cost competitive price,” Budge says in this latest announcement.

“The primary factor in delivering an end product cost competitive with traditional manufacturing is the speed of the machine. This is why Aurora is looking outside traditional 3d printing markets to sectors like mining, oil & gas, marine and automotive. The year ahead is looking extremely exciting.”

Also indicative of Aurora’s forward momentum was the announcement earlier this week of an AU$5M private placement.

One very pleasant part of this company’s regular announcements is the concrete steps they’re taking, with demonstrable results, toward their grandiose plans. Big ideas aren’t a new thing in 3D printing, but carrying them out is still something of a novelty.

Via Aurora Labs

Aurora Labs announced an important milestone in the development of their rapid metal 3D printing process.