![The MakeX M-Jewelry desktop 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09a2b3a8e6.jpg)

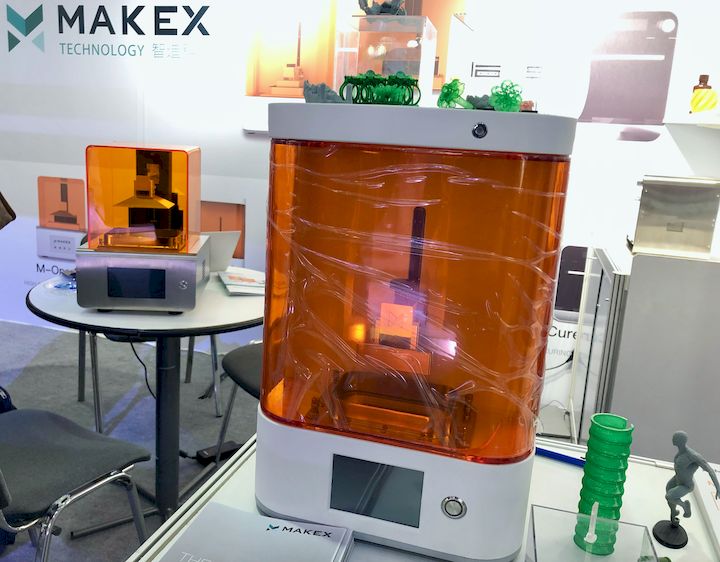

An interesting option for jewelers is the M-Jewelry DLP 3D printer from MakeX.

MakeX, based in China and USA, first came to our notice a few years ago when they introduced the M-ONE an inexpensive, but high-quality resin-based desktop 3D printer. That machine was followed by the Migo, which was very inexpensive, around US$200, and apparently sold very well.

Since then the company has been developing more advanced 3D printing products, including a curing station, and now offers a machine dedicated to the jewelry market, the M-Jewelry.

This machine is a DLP-powered resin 3D printer capable of very fine resolution, but only within a small build volume. The small volume is not an issue for jewelers, because that’s the sizing they typically require for their works of art.

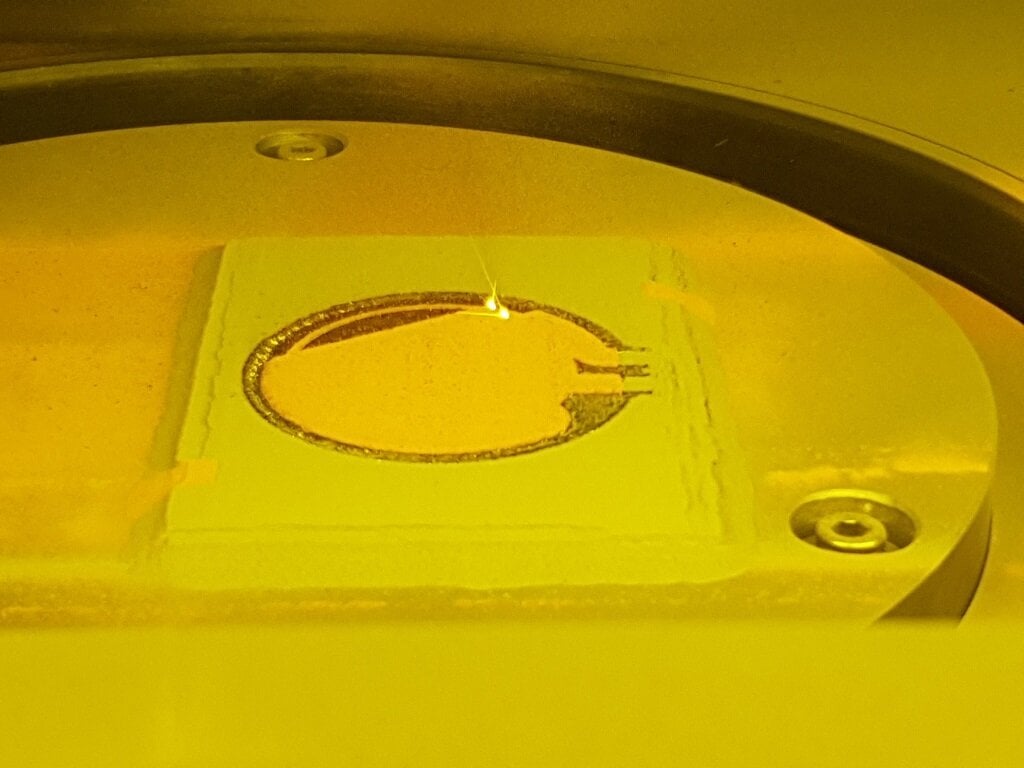

While they offer a number of different resins for their equipment, MakeX expects that the M-Jewelry will typically use their cartable jewelry resin. This material will be used to 3D print a positive representation, which will be then encased in a plaster. After setting, a furnace burns out the solidified resin leaving a cavity. This can then be filled with liquid metal to cast the final jewelry part. It’s the lost-wax process, except without wax and using 3D printing resin.

![MakeX’s casting resin [Source: MakeX]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09a2b8bea9.jpg)

In their online store, this resin is listed at US$179 per cartridge, a typical price for high-quality casting resin.

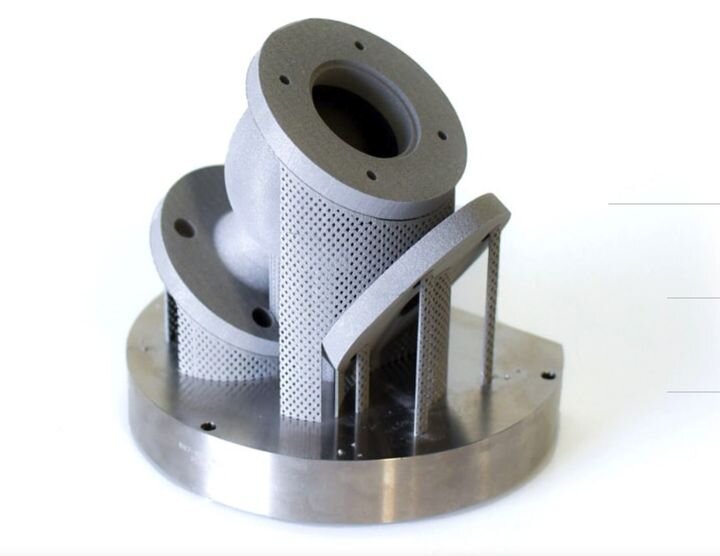

The M-Jewelry is actually three different models, differing only in build volume and resolution. They are the U60, U50 and U30.

The reason for the different models has to do with the optical system design. Their light engine is a DLP projection device that has a fixed array of light pixels. Each of the machines focus the pixels onto a 2D area that differs in size between the units.

Because the number and aspect ratio of the pixels is identical regardless of how large or small the DLP image is projected, there is a simultaneous change in resolution and build volume. If the pixels are focused tightly on a small area, then you receive high resolution, but a more limited build volume. Correspondingly, if the pixels are focused to a larger area, you can build larger objects but the resolution might not be as detailed.

Thus the three models have build volumes and resolutions as follows:

-

U60: 75 x 46 x 130 mm at 0.058mm resolution

-

U50: 64 x 40 x 130 mm at 0.050mm resolution

-

U30: 43 x 27 x 130 mm at 0.033mm resolution

Note that the aspect ratio of all these machines is 1.6 when dividing the first two dimensions. The third dimension is 130mm in all cases because it is independent of the DLP focusing.

![Terrific detail on this 3D printed ring [Source: MakeX]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09a2bca1bb.jpg)

Output from these machines looks incredibly good, particularly on the U30, and will clearly be quite suitable for jeweler use.

The M-Jewelry machines start at US$3599.

Via MakeX

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.