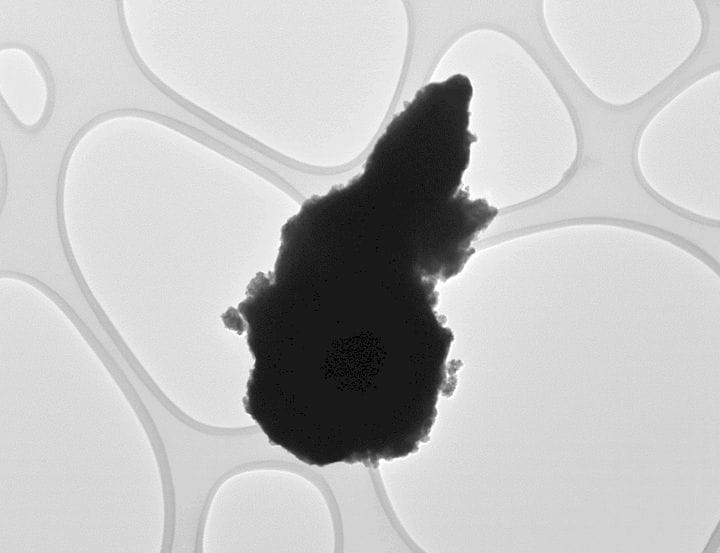

![A nanoparticle emitted by a 3D printer [Source: HSE]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09ba48991e.jpg)

A new report about 3D printing safety has been issued by the UK’s Health and Safety Executive.

The report, 70 full pages in PDF form, is quite extensive and investigates the well-known problem of 3D printers emitting nanoparticles and volatile organic compounds (VOCs) while in operation. I say “well known”, but I mean “well known in the 3D printing community”. Outside that community there is vastly less understanding of the problem.

While we’ve known about the issue for years based on some scientific investigations, it’s mostly been ignored by 3D printer operators and 3D printer manufacturers. Today very few machines are equipped with safety features to capture or filter out the bad emissions. Even worse, many people operate their 3D printers and ignore the problem. I’ve even heard of people running a 3D printer overnight next to their bed, causing me to shudder.

Recently UL issued a very extensive report on the issue in which they listed and measured emissions of near 200 different VOCs, some of which are carcinogenic. This seems to have begun to draw wider attention to the problem.

In the UK, the Health and Safety Executive issued their report perhaps due to the work UL had undertaken. Nevertheless, this report is different, not so much in the content, but where it’s directed.

The report is intended to be reviewed by UK schools and offices using 3D printers. They say:

“HSE undertook laboratory tests to assess whether polymer filament desktop 3D printers released hazardous particles and vapours which a person nearby could breathe in; they also investigated control measures to reduce these emissions.

These printers emitted many particles of a size range that can potentially enter the airways and lungs. Some plastic filament materials, when heated, were found to release vapours known to be hazardous to health.”

![The 3D printer emissions test set up [Source: HSE]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09ba4ecd37.jpg)

The report also makes recommendations in addition to merely reporting that bad things happen. This is the interesting part. They say that emissions could be controlled by:

-

using polymer filaments from reputable suppliers

-

choosing filament materials with a lower emission rate

-

setting a lower operating temperature for the nozzle of the printer through which the

polymer filament passes

-

placing the printer inside an enclosing hood fitted with a suitable air filtration system

-

waiting sufficient time for printer emissions to clear (i.e. the clearance time) before

opening the enclosing hood.

They’re making specific recommendations that will, no doubt, be taken up by many educational institutions in the UK, a large market for 3D printers. These recommendations will certain influence how UK educators — and others — will operate their machines.

It could also influence how they purchase their equipment. The report strongly implies equipment with enclosures and air filtration systems would be a better option than the more common and inexpensive open format 3D printers.

Thus we may soon see a shift in market purchases in the UK. I also suspect that this could be the tip of the iceberg, as other jurisdictions may begin to issue similar reports and recommendations.

Imagine if, say the EU and US authorities made such recommendations. Then we’d see some changes in purchasing behavior — for the good. But it may mean that those companies producing open format 3D printers may have to consider changing their machine design.

Via HSE (PDF)

We were able to view video footage of the 3D printing hair-caught incident from last week and have determined exactly how it occurred, and how to prevent it from happening again.