![1969 Camaro with 3D Printed Hood Fender and Quarter Grill Vents [Source: Bowler Transmissions ]](https://fabbaloo.com/wp-content/uploads/2020/05/1969-chevrolet-camaro-hardee-ft-011_img_5eb092de5803e.jpg)

Charles Goulding and Ryan Donley of R&D Tax Savers examine 3D printing applications for car parts – specifically the popular Chevrolet Camaro.

Rumor has it that 2023 may be the last year for the Chevy Camaro. The Camaro has been one of the most popular car brands in the United States since 1966 but, recent developments leave the future of the car in doubt. A similar situation in 2002 saw the Camaro take a hiatus until it returned in 2009 and was the best selling muscle car every year from 2010 through 2014. Even though uncertaininty lies ahead for an American classic, hope is not lost as enthusiasts and companies alike are turning to 3D printing to prototype and experiment with parts that were orginally poorly desgined, not produced anymore, or too diffiuclt to reproduce and help keep Camaro’s out on the road even after the brand could come to an end.

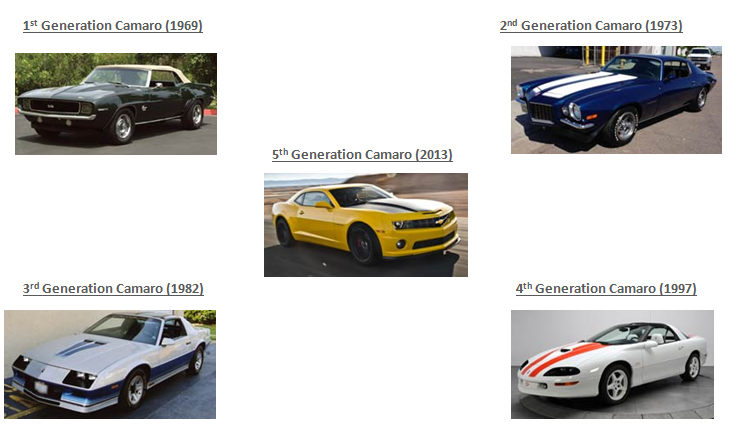

Provided below is a glance at the Camaro through the years as well as 3D printed parts related to generations of Camaros.

Chevy Camaro LS3 V8 Engine

![Chevy Camaro LS3 V8 Engine [Source: Thingiverse ]](https://fabbaloo.com/wp-content/uploads/2020/05/Camaroengine1_img_5eb092df0550a.jpg)

This engine was designed by Eric Harrell who has vast knowledge in this field as he has designed several other engines for various car makes and models. Overall the Camaro engine requires 200 hours of 3D printing with the engine block taking up 72 hours alone. In order to achieve such a design, modeling was done from CAD files, pictures, specs, and service diagrams of the actual engine and provides a highly capable combination of technology and performance to assemble the engine exactly like the real one.

Backing Plates for Inferno Camaro

![Backing Plates for Inferno Camaro [Source: MatterHackers ]](https://fabbaloo.com/wp-content/uploads/2020/05/camarobackingplates1_img_5eb092df4573c.jpg)

The backing plates come from another 3D printing car enthusiast, Michael O’Brien, who utilizes the technology to help design and manufacture numerous accessories for cars. The plates were designed by Chris Grey and implemented by O’Brien and his Roadster Shop on the Inferno Camaro. Upon completion of the Camaro totally, the car would go on to win the Goodguys Rod & Custom Association Gold Award at the SEMA show.

Grille for Supercharged Pro-Touring 1969 Camaro

![Grille for Supercharged Pro-Touring 1969 Camaro [Source: V8TV ]](https://fabbaloo.com/wp-content/uploads/2020/05/camarogrille1_img_5eb092df7f9ee.jpg)

The 3D printed grille comes from the team at V8 Speed & Restoration Shop who frequently blend the new technology of 3D printing with the old technology in classic cars. The grille of the 1969 Pro-Touring Camaro is one of the signature elements of this innovative car and had to be perfected in 3D printing production. An original grille for the vehicle was scanned first, and then designed in a modern version to be turned into a 3D printed part. The car was then brought to the SEMA Show in Las Vegas where it was well received.

1969 Camaro with 3D Printed Hood Fender and Quarter Grill Vents

The 1969 Camaro 3D printed hood fender and quarter grill vents — see top of this piece — are designed by Detroit Speed and Craig Hardee who implemented numerous custom-fabricated parts to this classic Camaro. The unique Camaro boasts high performing custom parts that are both 3D printed and custom machined that required numerous hours of work. Upon completion, the Camaro was invited to be a part of the SEMA Battle of the Builders competition, a familiar competition for Detroit Speed. Though the Camaro did not win this time, the impressive vehicle is proof of the incredible capabilities of 3D printing in the car universe.

Individuals and companies who engage in 3D printing of car parts could be eligible for an R&D Tax Credit which is briefly described below.

The Research & Development Tax Credit

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

-

Must be technological in nature

-

Must be a component of the taxpayer’s business

-

Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

-

Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum tax for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

Through the years, the derivation of the word Camaro has been subject to controversies. In automotive circles, the Camaro is known as a small vicious animal that eats Mustangs. When the vicious animal needs replaced parts, 3D printing may be the answer.

Charles Goulding and Preeti Sulibhavi consider how two prominent automotive firms, Ferrari and Ford, are using 3D printing.