![Digital Modelmaking: Laser Cutting, 3D Printing and Reverse Engineering” by Helen Lansdown [Source: Amazon]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c9c0a985.jpg)

This week’s selection is “Digital Modelmaking: Laser Cutting, 3D Printing and Reverse Engineering” by Helen Lansdown.

Modelmaking is an ancient traditional skill that remained essentially unchanged for hundreds of years. Models of people, buildings and machines were built using manually operated tools with techniques such as sculpting and cutting.

Many models are still made in this way, but these days there are far more powerful methods of producing models, and some that can produce models essentially impossible to practically produce using traditional approaches.

Today’s techniques are digital, where the designs are created using advanced CAD systems and the actual “making” of the model parts is done automatically through computer controlled machines. Machines like laser cutters, CNC mills and, of course, 3D printers.

In this book Lansdown explores the basic aspects of several digital making technologies that are increasingly used to produce intricate models:

-

Laser cutting, to quickly produce 2D materials that can be assembled into 3D structures

-

CNC milling, to inexpensively create simple 3D objects that can be incorporated into a model

-

3D Printing, to produce highly complex structures in a consistent manner

The key here is that there are a combination of tools at the ready, and the model maker must choose the right tool for the job. For example, while you could 3D print a flat rectangular sheet, it would be far cheaper and faster to simply laser cut a piece of the same geometry. By using the optimum tools for each component, one can optimize the cost and speed to develop a model.

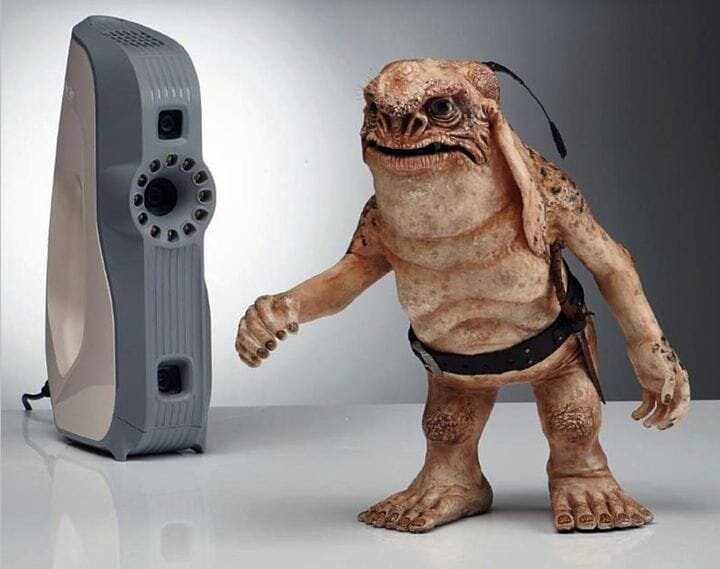

The book also explores the concept of reverse engineering. This technique usually involves 3D scanning a previously made object to obtain a rough outline of the object’s geometry. Then in a 3D CAD tool it’s possible to “trace” over the object’s outline to re-create a digital representation of the original object.

Usually this is done to enable production of mechanical parts that no longer exist and have no digital 3D model, but in model making it’s done for two main reasons: capturing an existing shape that can be modified for purposes of a new style of model; or capturing a human face / head / hands / etc, so that they can be incorporated into a model being designed.

If you’re a traditional model maker and you’re contemplating a move into digital production, this book might be something to consider.

Via Amazon