![Bioprinting [Source: CollPlant]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08bdb16edb.jpg)

3D Systems has made a move! They have signed an agreement to deepen their work in the healthcare market.

The agreement is a partnership between 3D Systems and CollPlant, who happen to be an Israeli company that manufactures bioinks.

CollPlant 3D Printing

They explain their purpose:

“CollPlant is a regenerative medicine company focused on 3D bioprinting of tissues and organs, and on developing and commercializing tissue repair products for orthobiologics, and advanced wound care markets. Our products are based on our rhCollagen (recombinant human collagen) that is produced with CollPlant’s proprietary plant based genetic engineering technology.”

Their technology is quite interesting. They have performed gene-engineering on tobacco plants to include five human genes. This makes the tobacco plants literally produce real human collagen. The otherwise normal-appearing tobacco plants are carefully cultivated and then harvested to extract the collagen.

Evidently this process is quite efficient in both time and finances. It also has a huge benefit over competing systems, which harvest actual human collagen from cadavers. As you might suspect, there are some limits using that approach.

![CollPlant’s bioink [Source: CollPlant]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08bdb52464.jpg)

From this source of raw, pure human collagen, CollPlant then can reshape the collagen into a variety of shapes for different applications. One of the applications is to create a collagen gel suitable for use in 3D bioprinters.

However, as you may have gathered by this point in the discussion, CollPlant is essentially a materials company as their relationship to 3D printing. 3D printers are required to complete the printing equation.

3D Systems CollPlant Agreement

That seems to be the nature of this agreement, under which the following occurs:

“3D Systems and CollPlant recognized an unmet market need for a comprehensive solution to produce tissues and scaffolds for regenerative medicine applications. The companies intend to create integrated 3D bioprinting solutions comprised of state-of-the-art 3D bioprinters and BioInks to produce tissues and scaffolds. In accordance with the collaboration agreement, both companies may use a combination of 3D Systems’ printers, CollPlant’s BioInks, and new formulations of rhCollagen-based BioInks jointly developed by the companies, for their own products, as well as for deployments with third parties.”

Effect on 3D Systems

What’s interesting is that 3D Systems does not currently produce a 3D bioprinter. Their current product line includes equipment for metal, plastic, casting and dental applications, but no biological applications. I presume that will change as the company’s R&D department is no doubt already in the midst of developing this type of device.

Having built many complex machines with several different 3D printing processes over the course of decades I am confident they will be able to produce an effective bioprinter in short order. This will allow them to sell a new products to a new line of business, the first for 3D Systems in many years.

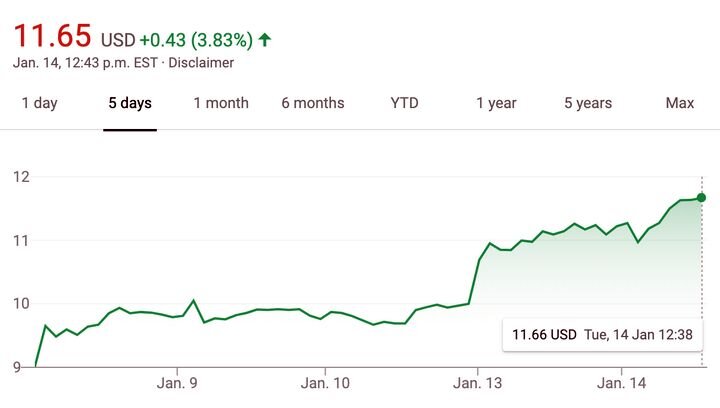

3D Systems Stock Healthcare

But can they? It seems that the market thinks so. Upon the announcement of the agreement, 3D Systems’ stock price jumped from US$10.00 to around US$11.60 as of this writing. To put this shift another way, their market capitalization grew by about US$200M. The market thinks this move is worth US$200M to 3D Systems.

![3D Systems’ stock price rose suddenly upon the announcement of the CollPlant deal [Source: Google Finance]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08bdb893ae.jpg)

I believe this is quite possible, as investments usually are in multiples of annual profit. If one were to suggest, say, that 3D Systems could make an additional US$20M per year with this new line of business, then the multiple would be 10X. That seems achievable, given the resources 3D Systems has at hand and the enormous size of the healthcare market.

I also believe this is a good move because it leve

rages 3D Systems’ increasing focus on healthcare applications. It also reinforces my suspicion that 3D Systems is gradually turning into a healthcare company.

We’ll have to watch to see how this plays out. If successful, we’d see a line of 3D Systems bioprinters and plenty of sales to healthcare organizations in a year’s time.

Via 3D Systems