Charles Goulding and Greer Veon examine the benefits of using an internal makerspace for corporate or manufacturing innovation.

Many companies rely heavily on manufacturers who are expected to provide a high quality of skills and expertise in areas such as technology, engineering, and mathematics.

Companies that are invested in these areas are encouraging their product designers and manufacturers for more innovation efforts. Thus, the growing number of makerspaces in business and manufacturing areas serves as the optimal approach to research and development efforts.

Makerspaces have served as an educational tool for many academic settings, but now the tools provided can forge technological advancements for prototypes, products, and production. Companies invested in the 3D printing industry should look into the benefits makerspaces can bring to their research initiatives.

Stanley Black & Decker’s Manufactory 4.0

One of the best examples of business and manufacturing makerspaces is powered by Stanley Black & Decker, a leading global diversified industrial in tools and storage, security services, and engineered fastening. The Manufactory 4.0, located in Hartford, Connecticut and inspired by the original Manufactory founded in the early 1800s, is a “smart factory” that integrates advanced manufacturing technology and how these tools would be implemented into facilities across the globe.

Jim Loree, President and CEO of Stanley Black & Decker, says in a press release about their makerspace initiative, “Manufactory 4.0 serves as the heartbeat of the industry’s 4.0 efforts, helping out manufacturing operations rapidly adopt leading-edge technologies and ensuring our own global workforce is prepared for this new world through upskilling and re-skilling effort.”

Stanley Black & Decker’s Manufactory 4.0 focuses on technology for art modular robotic automation cells, mobile robots, and collaborative robots.

Yet, the same business innovations can be applied for companies invested in additive manufacturing technologies from the 3D printing industry. Companies that invest in the 3D printing industry and the use of makerspaces such as the Manufactory 4.0 will likely qualify for the federal R&D tax credit.

The Research & Development Tax Credit

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

-

Must be technological in nature

-

Must be a component of the taxpayer’s business

-

Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

-

Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum tax for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

The Power Behind Makerspaces and the Maker Movement

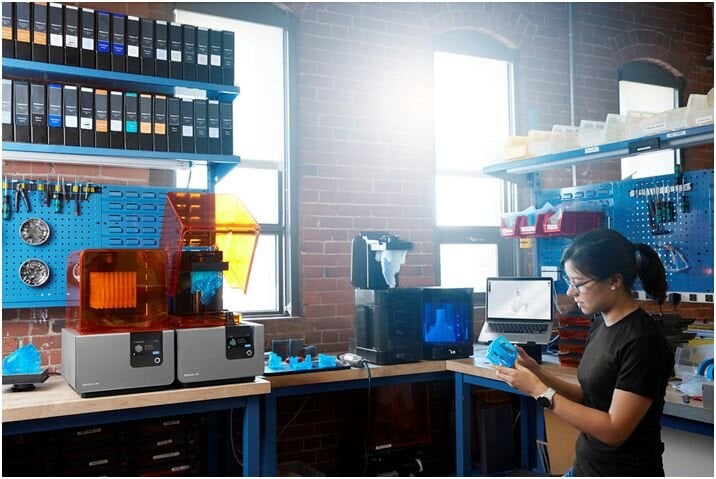

A place providing tools and collaborative community space, Makerspaces are known for fostering groups of individuals to conceptualize, design, and fabricate an idea. Sharing some of the aspects familiar in a woodshop or home economics class, individuals encounter different technology and materials to further their expertise. Makerspaces have experienced a wave of popularity from the growing number of individuals participating in the “Maker Movement,” a surge of interest in inventing through do-it-yourself (DIY) and do-it-with-others (DIWO) techniques to develop creative artifacts such as printers and electronic devices.

A surge of Makerspaces has been seen in an educational setting, such as libraries or community centers. They center on collaborative work and expanding one’s initial skillset, which makes makerspaces the optimal place for technological advancements for the global marketplace. Since these spaces provide the technology, materials, and tools to experiment with 3D printing, many of the same lessons students or members of a community gather from creating personal items can be translated in redefining operational systems and creating prototypes for many manufactured products.

Makerspaces, R&D Initiatives, and 3D Printing

As many companies seek opportunities to research new and improved products and systems, manufacturers and product designers may face uncertainties in finding the space, tools, and time to practice these initiatives. Companies experimenting with new areas of technology that could range from Computer Numerical Control (CNC) machine work to Computer-Additive Design (CAD) could find the normal production warehouses or workspaces to not suit new machines, 3D printers, or computers. Thus, makerspaces serve as a great alternative to the issues outlined below:

Safety

Makerspaces can define operating procedures for various equipment, planned access, and supervision by experienced personnel. These spaces can also address safety concerns by allowing manufacturers and product designers to define and prevent hazards with mixing materials, ventilation and exhaust air, and emergency power controls.

Flexibility

Since projects are in flux, makerspaces provide an area where multiple and diverse varieties of projects can be done. Multiple outlets, machines, and workspaces can be given so that supplies needed for different kinds of projects can be done without a lack of supplies. Structurally, these spaces also provide flexibility for working conditions. Lighting controls can allow for dimmable, tunable, and task lighting to achieve the right illumination and color options. Makerspaces are also equipped to provide optimal options for drainage, hold heavy loads of materials, and configuration of space for equipment installation.

Noise Control

As makerspaces serve as an educational and innovation tool, the space designs are equipped with a sound system to cater to specific noise criteria. Intentional architectural space and separation provides manufacturers the ability to work on specific projects without noise inhibiting the work on a printer or online design program.

Moving Forward

As the rapid growth of 3D printing technology looks to transform how we approach business and manufacturing, makerspaces can foster a place for company innovations and how manufacturers can learn, test, and apply new technology to product design and development.