3D printing is an amazing technology that allows designers, engineers and hobbyists to manufacture objects with complicated geometry layer-by-layer instead of subtracting material from a solid block.

It uses less material and enables rapid prototyping of different designs. It is not known for its speed, however. There are many different types of 3D printing, and some are faster than others. For example, Carbon has a relatively fast printing technology compared to Stratasys. But overall, speed remains a challenge for 3D printing.

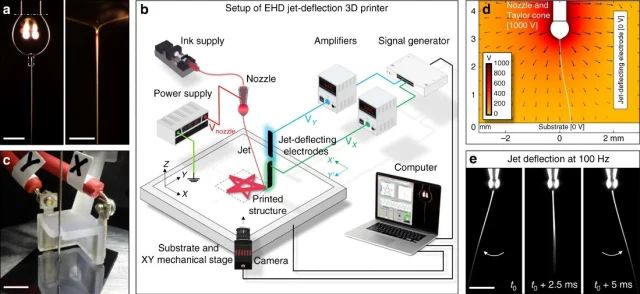

Researchers from the Catalonia Institute for Energy Research and Rovira University in Spain claim to have created an ultrafast 3D printing method that leverages electrostatic jet deflection technology. The technology they are improving is electrohydrodynamic redox (EHD-RD) 3D printing, an experimental approach to additive manufacturing first developed by ETH Zurich.

The approach allowed researchers at ETH Zurich to print a wide range of metals by dissolving and redepositing them in liquid solvents using electrochemical techniques. The results were ink-free 3D prints of polycrystalline multi-metal 3D structures. With this method, there was no need for post-processing.

How the New Ultrafast EDH-RP 3D Printing Works

According to the research paper “Ultrafast 3D printing with submicrometer features using electrostatic jet deflection,” researchers set up electrodes around an electrohydrodynamic 3D printer and applied voltages to continuously adjust lateral accelerations. According to the paper, the results were promising: “Through electrostatically deflecting the jet, 3D objects with submicrometer features can be printed by stacking nanofibers on top of each other at layer-by-layer frequencies as high as 2000 Hz.”

Bottom Line

The technology in question is still largely experimental, and there is no word on the viability of commercializing electrostatic hydrodynamic redox 3D printing. But the results of this new research from Spain indicates that EDH-RD additive manufacturing is flexible enough to overcome known limitations of speed.

Read more at ENGINEERING.com