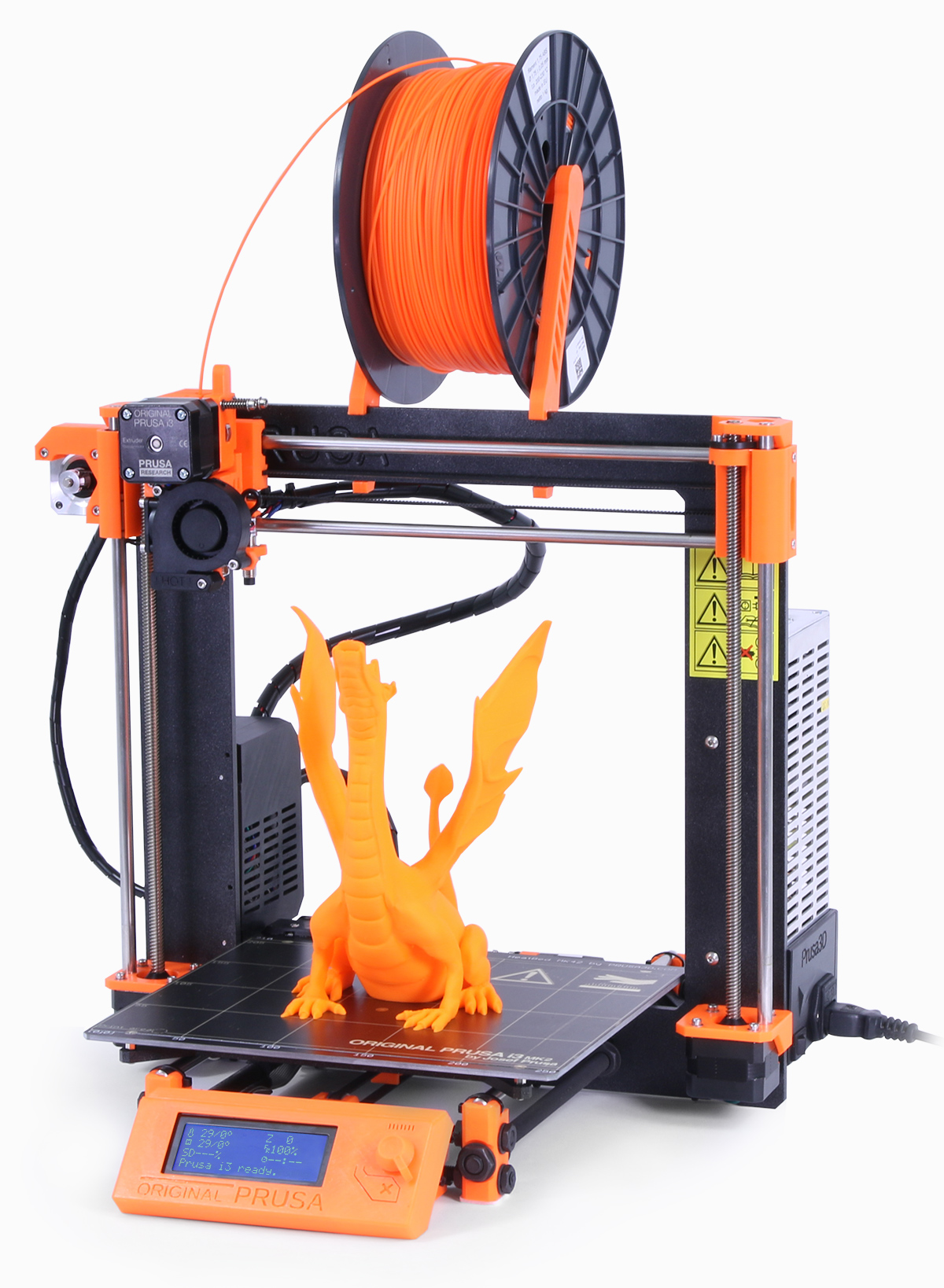

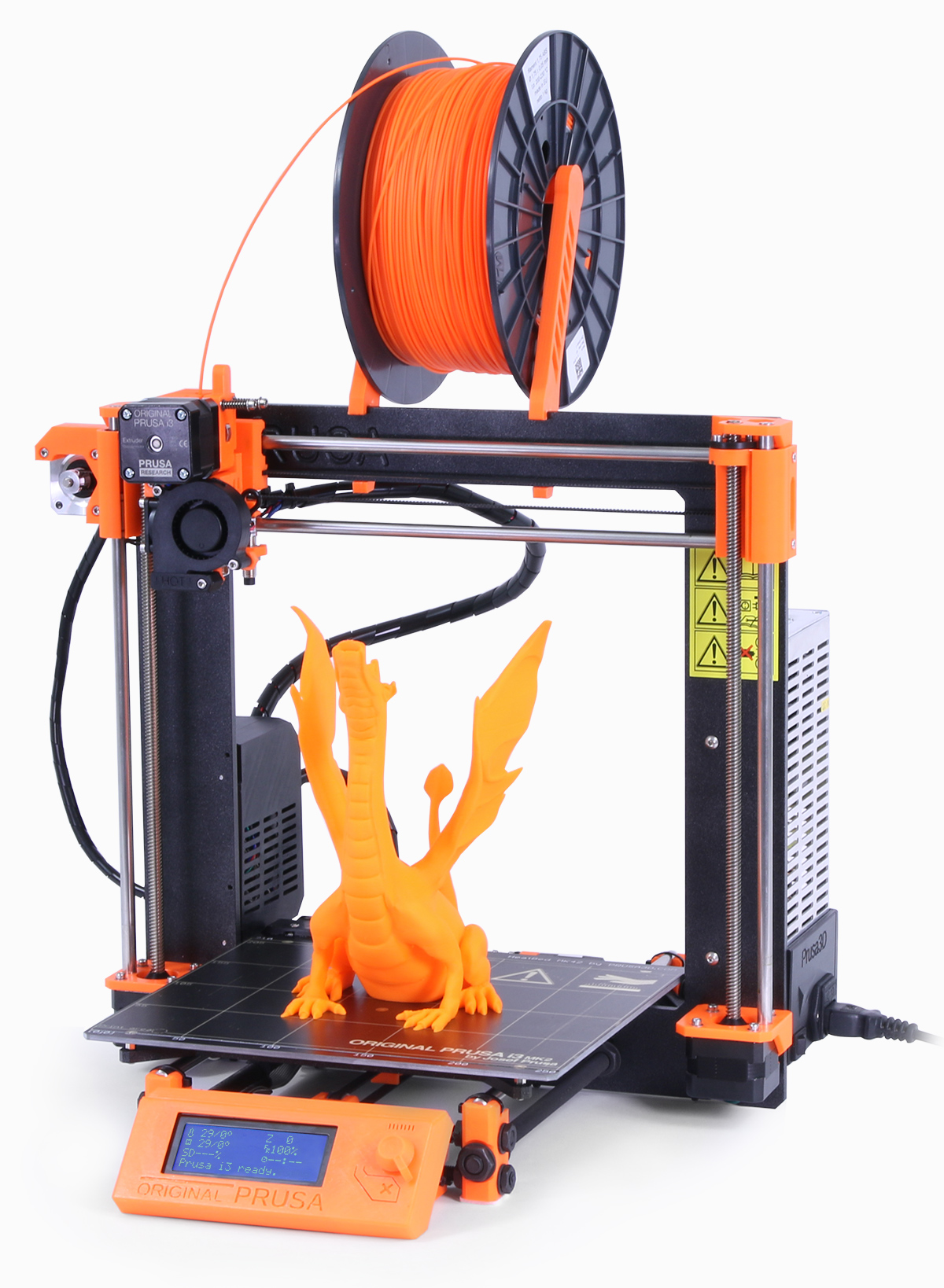

The Prusa crew have developed a rather sophisticated automated calibration system for their most recent desktop 3D printer, the Prusa i3 MK2.

We did write about the original MK2 back in May of this year when it was announced, but this week’s announcement is of some importance, as it dramatically – very dramatically – increases the reliability of this 3D printer.

As every 3D printer operator knows, desktop 3D printing can be risky business: a significant percentage of attempted prints fail for a variety of reasons. One of the most frequent causes of print failures is a poorly calibrated surface.

Without proper calibration prints may not adhere properly and thus fall off the bed in mid-print, causing at least print failure, wastage of material and in some cases printer damage if loose bits fall in sensitive mechanical locations. This problem is sometimes made more challenging with self-built 3D printer kits that may be assembled slightly differently from person to person.

The Prusa i3 MK2 now includes hardware and software to overcome virtually all such issues. In fact, its calibration system solves no less than three calibration factors.

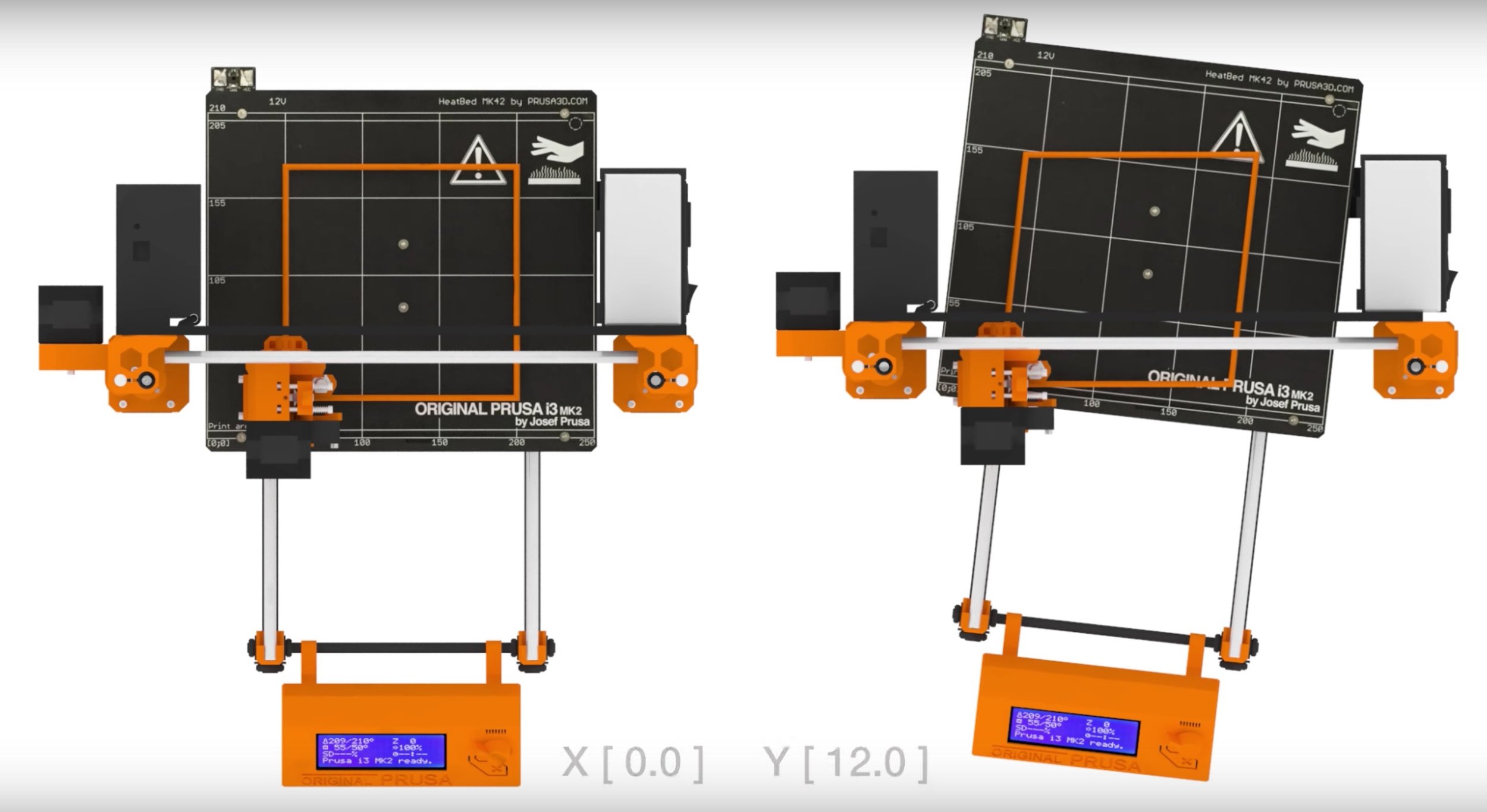

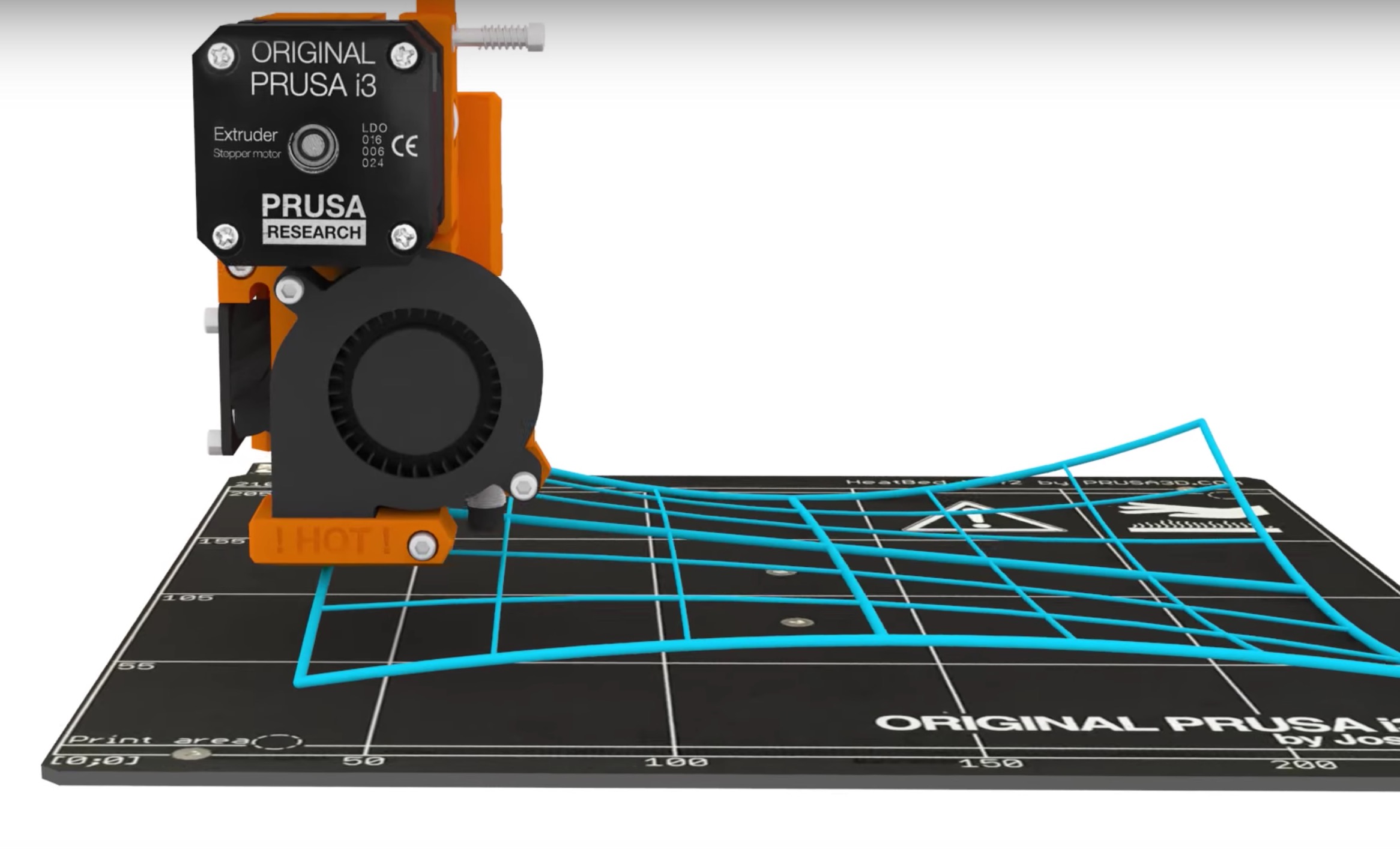

First, the system solves for improperly aligned print beds. In some cases, the bed is very slightly rotated around the Z-axis. This can lead to permanently misshapen prints: a square becomes a parallelogram, for example. The MK2 calibration system includes a probe that seeks four pre-defined points on the print surface and, after measuring their location, adjusts the printing motions to compensate.

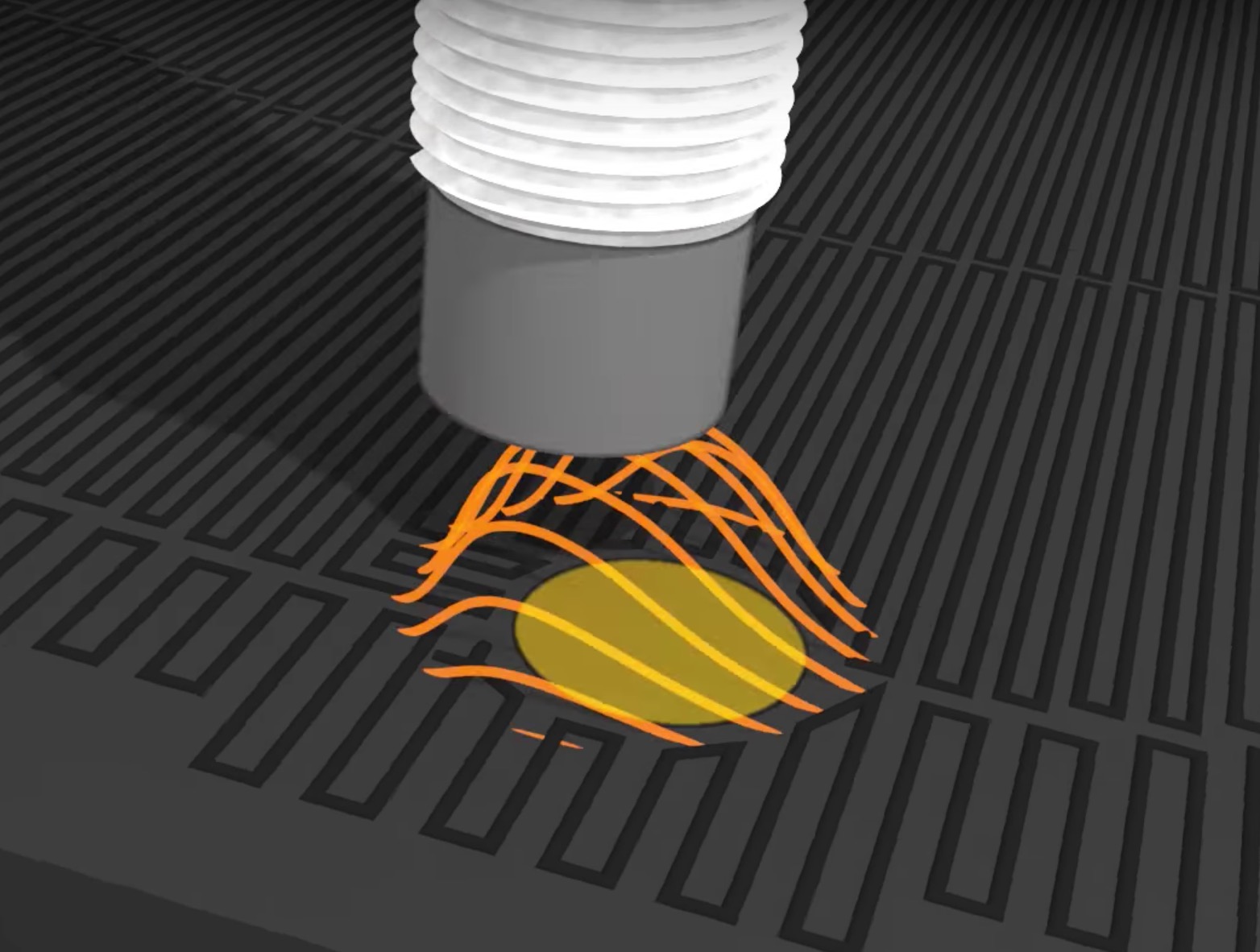

Secondly, the calibration system measures nine points to determine the un-evenness of the print surface. While the print surface may visually appear to be perfectly flat, it likely is not. Without calibration, the nozzle will encounter varying gaps to the surface as it moves about – and with an incorrect gap plastic adhesion may be compromised. The MK2 “knows” the “terrain” and once again compensates for the changing surface.

Finally, the MK2’s calibration system ensures the Z-gap is perfectly correct for optimum adhesion of the print’s first layer.

Check out how it works in this video:

There are other desktop 3D printers with automatic calibration or even “assisted” calibration, but there’s not many as comprehensive as the new Prusa i3 MK2’s system.

The work that Prusa Research has done to continually improve this design has resulted in great success for the small company. Actually, it seems they’re not so small anymore, as founder Josef Prusa tells Fabbaloo:

We are now at 1000 printers sold every month, I am pretty proud 🙂

That’s a very large number of 3D printers!

Via Prusa Research