Multiple readers have contacted us asking for advice on the now-controversial launch of the NexD1 jetting 3D printer.

The concept of this machine looks very good: it’s said to be a jetting 3D printer that mimics Stratasys’ PolyJet technology.

If you’re not familiar with PolyJet, allow me to bring you up to date. It uses photocurable liquid polymers, as you might find in typical laser/DLP 3D printers, but in a very different way. The liquid is delivered drop-by-drop using very high resolution print heads, the same type you might find in a high resolution paper printer. The droplets are sprayed out in one pass, then on the back swing, the head engages up a powerful UV light source to solidify the resin. Their process is about ten years old now, and has proven highly successful in the market.

Now a Berlin-based company, Next Dynamics, has apparently launched a machine, the NextD1, that uses their version of the same process. And you’d expect similar results.

The company has stated the machine can use up to six different resin materials at the same time. For reference, the Stratasys PolyJet equipment can now use up to six concurrent resins on the J750 model – and mix them in arbitrary combinations. While the J750 can cost multi-hundreds of thousands of USD$, the USD$3,000 NexD1 can apparently do the same.

The company has also pointed at unusual uses of the technology. For example, one of the resins could be conductive, meaning you could theoretically 3D print a solid model with conductive traces embedded within, or perhaps a 2D circuit board made of plastic and conductive material. They also have plans for producing castable, magnetic and other unusual materials.

This all sounds very good, and as a result the company has raised more than USD$500,000 on their ongoing Kickstarter campaign.

However, the comment section on their Kickstarter has been raging with controversy, largely surrounding two key questions:

- Has the machine actually been seen operating by anyone?

- Why do some of the color prints look suspiciously similar to those from other machines?

It seems the company is planning a public demonstration of the machine, but as of this writing that has not happened yet. However, there’s some very suspicious comments written by some. This report came form a 3D print operator who saw them at a Makerfaire:

The second was a printer from http://next-dynamics.com/ (which claims “Print thousands of different materials and colors with a single print”, despite only having 3 inputs) that was supposedly jetting resin like an Objet. This printer supposedly had multiple materials (including a conductive material) fed from cardboard boxes with nozzles sticking down. The guy running the booth swore up and down when challenged that all of the prints he was showing (most of which looked suspiciously similar to Objet prints I’ve seen in the past) had been printed on that machine (which, unsurprisingly, was not running). One of the pieces was even chipped, so I could see that it was definitely made of resin. One of the prints, though, which he repeatedly confirmed was an un-postprocessed print from the same printer, was clearly an FDM print that had been acetoned to within an inch of its life. This was the common treefrog print in two colors, which I knew very well would not look like what he was showing if printed the way he claimed to have done it. The print had also broken in places, revealing FDM infill (something that I’m fairly confident is impossible with resin-jetting), and there were a few other classic FDM artifacts that were. I pointed out the infill, and he doubled-down by claiming that it (including the top-surface bridging over infill that was slightly visible through the translucent filament) could be done with his process.

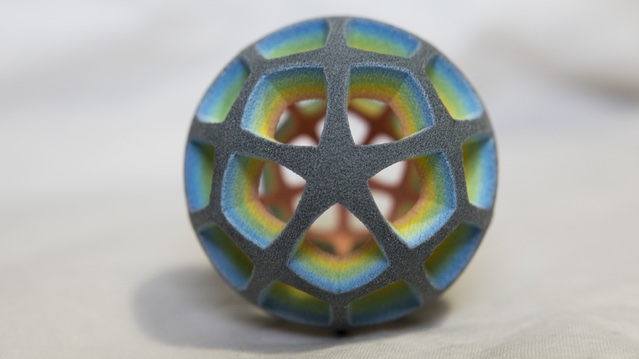

The Next Dynamics process could theoretically produce color objects, and so the company published images of a color print, shown here. The comments in the Kickstarter suspect these prints look suspiciously similar to that you’d receive from Shapeways’ color process, and indeed it does to my eye, having personally used both PolyJet and ZCorp equipment.

In this image, you’ll note the very broad structures. This is quite typical of ZCorp powder color 3D prints. I’d be more impressed if there were thin walls on an example.

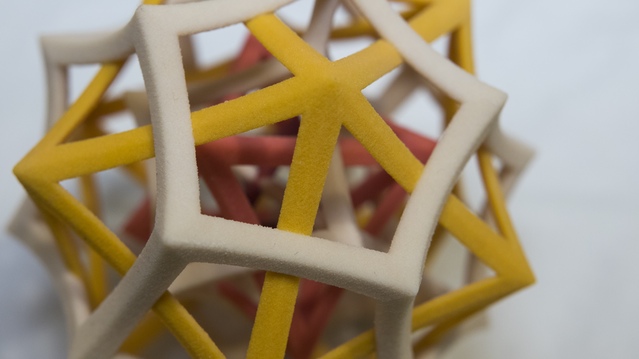

But the company has shown one here, in two colors only. This model likely required a very substantial amount of support structures to print correctly. Was this print produced on the NexD1? They say so, but given the suspicious nature of the previous image, I’m not sure.

[UPDATE: as per this damning summary of events here, it appears that this interesting geometric design is actually a proprietary design by Bathsheba Grossman, that is publicly available ONLY on Shapeways 3D print service, suggesting that the NexD1 folks simply got one from Shapeways and put it on their campaign to appear that it had been printed on their equipment.]

Another very curious thing I noticed in their introductory video was the explanation of the technology.

Here you see an image of a nozzle dripping liquid resin. But it’s a SINGLE nozzle, wholly unusable for a PolyJet-style system in which you’d need hundreds of adjacent tiny nozzles like you’d see in an inkjet machine. I cannot imagine what the purpose of a single nozzle could be in this system, and why they would show this in a video.

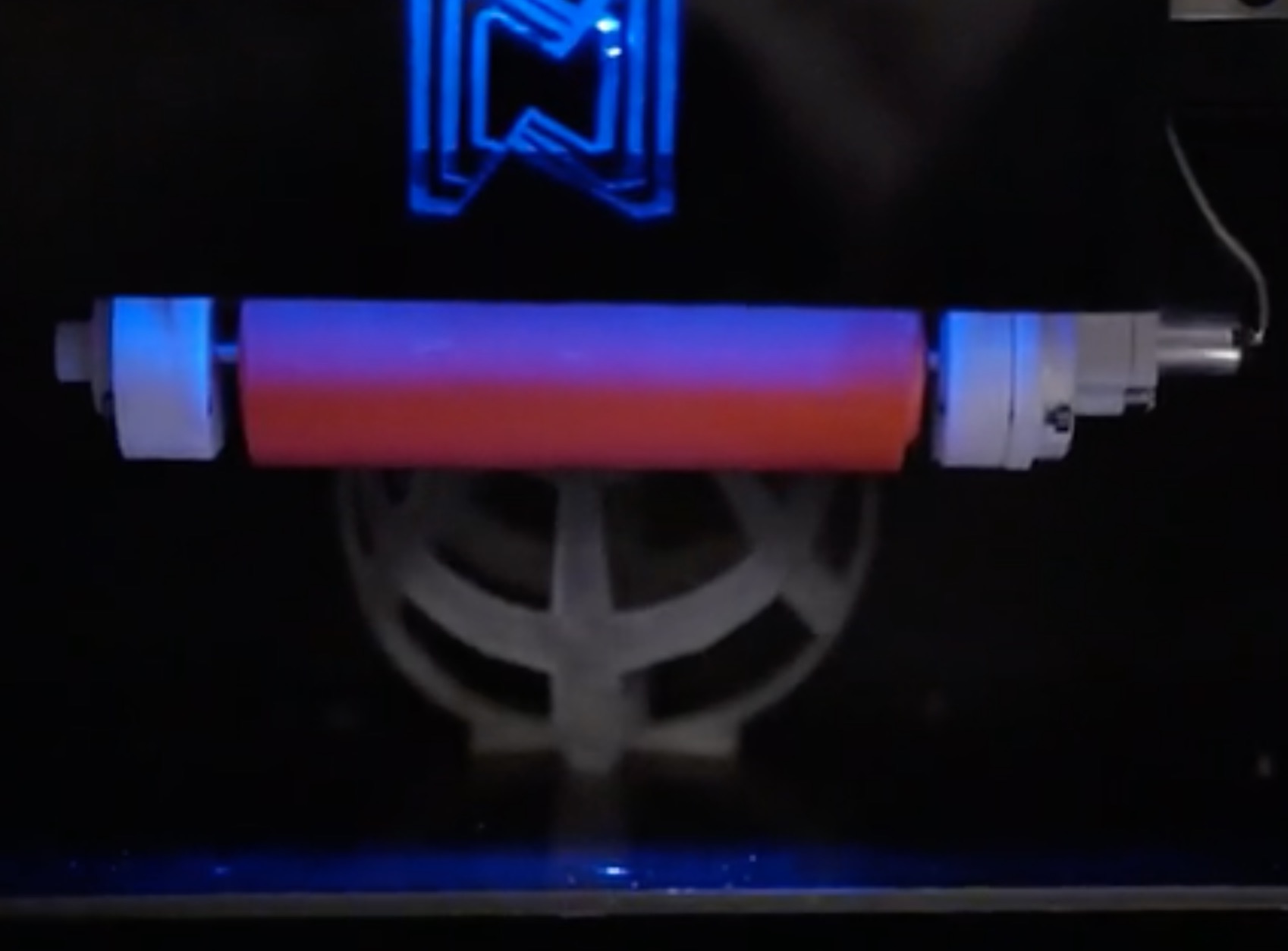

But hold on, later in the video they do show a multi nozzle arrangement, as seen here.

But wait, we then see a time lapse of a print operation. Looks good except for one thing: There is no support material visible. In a PolyJet-style system, there can be NO overhangs, because the liquid simply falls to the print surface. On a PolyJet machine you constantly see massive amounts of support material providing 100% support for anything over zero degrees of overhang.

Perhaps they’ve figured out some way to simultaneously fuse the liquid immediately as it leaves the nozzles, but that would certainly clog them up with solidified liquid almost immediately.

And there’s something else wrong with this time-lapse: there is no visible UV light shadowing the print as it proceeds. Maybe they have a UV light source that’s invisible, but that’s not the case on actual PolyJet machines. When is the UV light on and off? How is the liquid being solidified? How does the liquid not immediately drip to the bottom when encountering overhangs?

This time lapse print does not look like a PolyJet process in any way to me.

And I believe there’s one other major issue with this product: the PolyJet process is still under patent by Stratasys as far as I know. Were this product come to the market, they might be getting a letter from someone about it.

It may be that the folks from Next Dynamics have a machine that actually works, and it is certainly a very powerful process for a desktop machine. But in business it’s always the execution that counts the most, and it appears that Next Dynamics owes their backers some explanations to prove they are actually executing. Kickstarters are often a matter of trust that the company will indeed produce the advertised equipment, and that trust is gained through honest portrayal of the machine and its process.

Via Next Dynamics and Kickstarter