I saw a post somewhere about someone 3D printing a waterproof container and had some thoughts.

First, it’s actually not that easy to produce a truly waterproof 3D print, even though you may be printing what some call a “watertight” 3D model.

There are a couple of reasons, with the first being that typical 3D printers using the extrusion process tend to produce rather porous prints. The cause is due to the nature of the layers extruded during printing.

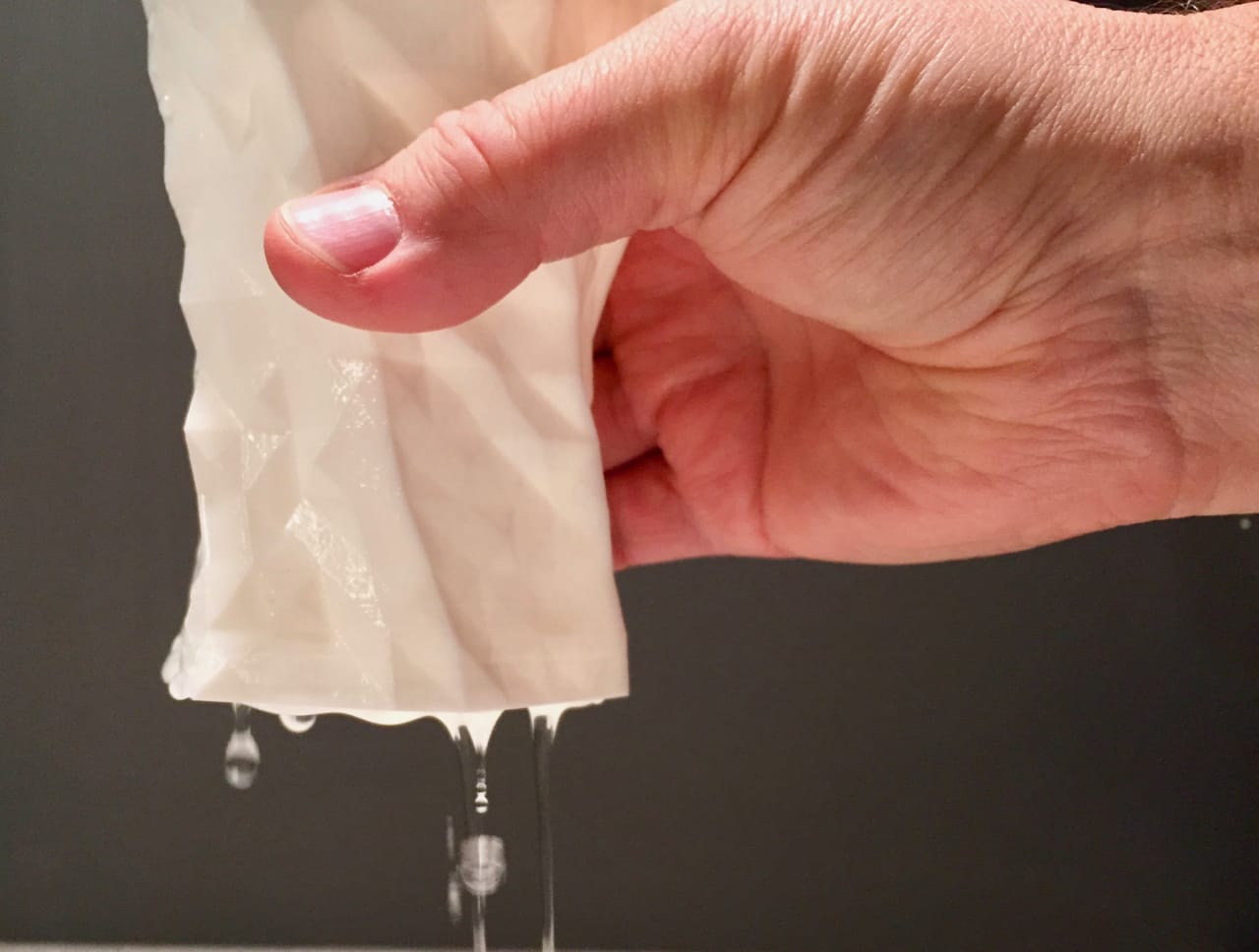

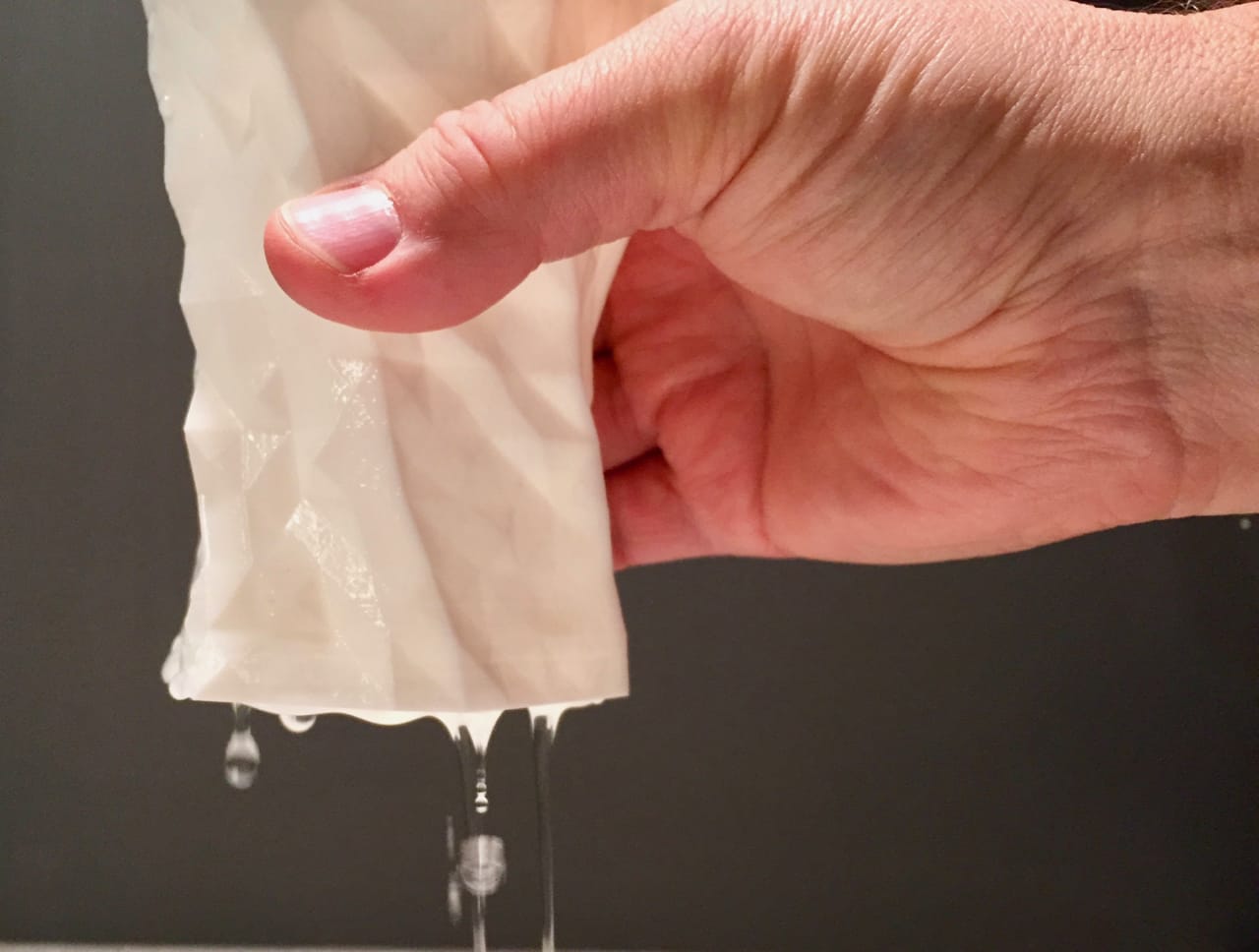

Visually, a 3D print might appear to be water tight, but it’s possible that there are very small gaps at points where the layers meet. While this tends not to happen in long, continuous extrusions, more complex structures may cause the extruder to move in ways that are somewhat more likely to cause gaps.

Through these gaps liquids may slowly flow, eventually compromising any waterproof ideals.

The layer gaps are likely not significant and it’s true that many 3D printed objects are actually waterproof by chance. However, if you wanted to 3D print an object that MUST be waterproof, then you have some challenges.

Another potential issue is that some plastics, and I’m looking at you, PLA, tend to soften and eventually dissolve if exposed to water for any length of time. While a print would certainly survive a dip, don’t count on storing water-based liquids in a PLA container for long periods. The softening would almost certainly increase the odds of a layer leak occurring.

There are a couple of techniques you could try to reduce the odds of leakage.

Thicker layers: One way is to print with coarser extrusions. If you change from 0.150mm layers to 0.300mm layers, then there are half the number of layer interfaces, reducing the odds of a leak.

More Perimeters: Another approach could be to increase the number of perimeters / shells / skins or whatever your term is for the exterior surface layers produced. This is something easily specified in most 3D printer slicing programs. By adding more perimeters there are more barriers to get through, reducing leakage.

Go Solid: If more perimeters isn’t your game, then perhaps you’d like to 3D print the object with 100% infill. This would certainly strongly reduce the chance of leakage, as there would be a tremendous amount of material to get through.

Post Processing: There are some 3D models that would simply be difficult to waterproof with any of the above techniques due to the geometry: perhaps there are thin walls that can’t really be affected. In these cases you should consider post processing your print to seal the surface. The ABS smoothing technique with acetone could do this, or you could add an epoxy mix like XTC-3D to smooth and seal the surface. Finally, there are a number of conventional sealants one could use, including paint.

Alternate Process: Instead of 3D printing using the extrusion process, consider using another process, like SLA, which can produce continuously sealed layers more reliably than extrusion. However, it may be more expensive to do so, and if using the print for drinkable fluids, you’d have to ensure the material and printer are both food safe. Hmm, I suppose that goes for all of the above, too.

Waterproof 3D printing? Possible, if you take the right steps.