A new kit to convert your desktop 3D printer to ceramic capability is about to launch.

Developed by Germany’s StoneFlower, the “Ceramic 3D Printing KIT” includes the hardware necessary to 3D print clay and other paste-like substances.

The specifications indicate the device can deposit layers as small as 0.3mm, which might seem large when talking about thermoplastics, but is quite appropriate for the typically coarser clay prints.

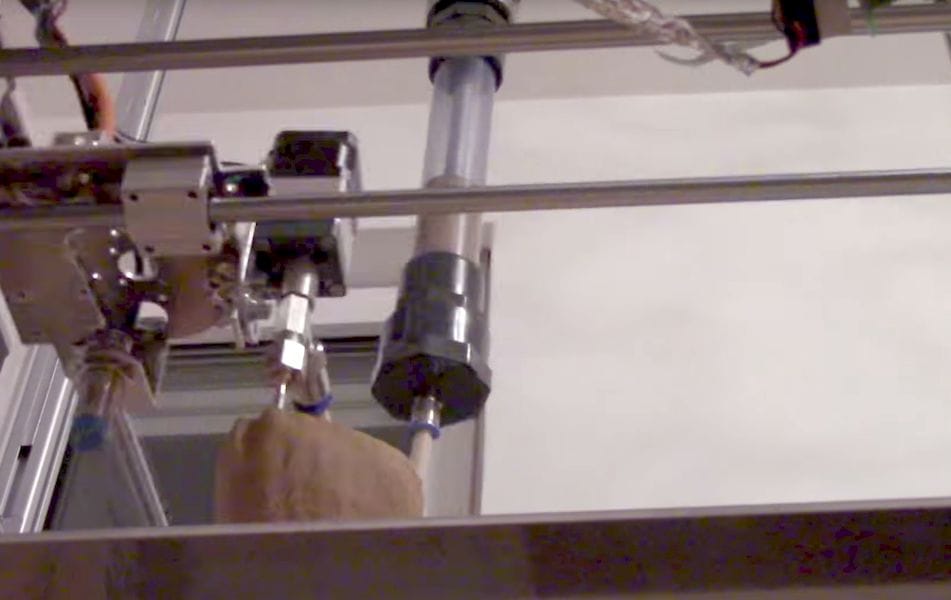

As you can see in the video, the system involves a rather tall piston that must be attached to the top of your 3D printer, where a syringe-style mechanism is used to power the paste through the system to the extruder. It has a good capacity per run of 500ml of clay, or about 900g. This means this kit should be able to be installed on larger devices.

Unlike most other paste extruders, the StoneFlower concept avoids the use of compressed air. That method is obviously noisy, but is also less accurate: compressed air introduces a bit of “bounce” when starting and stopping the system during printing. Instead they say their syringe system is far more accurate, and it makes sense to me.

The Ceramic 3D Printing KIT also includes an auger mechanism at the nozzle, which apparently is able to eliminate air bubbles within the material flow, which would otherwise pollute the final 3D print with unsightly and structurally weakening gaps.

A side effect of this is that the system is able to handle much more rigid pastes, and this is of particular interest with clay. Most paste extruders require rather liquidy clays, which have the unfortunate effect of slumping once extruded. This means you will have great difficulty in 3D printing finer details and especially overhangs.

The only extrusion-style ceramic 3D printing system we’ve seen that overcomes this was an experimental system that involved a massive power piston to push “raw”, unlubricated clay through a nozzle. But this system has yet to hit the market.

While the StoneFlower system does not accept raw clay, it requires only slight wetting. They say:

The StoneFlower Ceramic 3D Printing KIT works even with thick just slightly diluted clay, providing mechanically stable prints.

That’s a huge advantage over most of the paste extruders you will see on the market.

Finally, they also say that they’ve designed the system to permit easy disassembly for cleaning, something that is mandatory in ceramic systems. You don’t want stone solidifying in your material path, do you?

One thing I am wondering about is the difficulty of installation of this kit on various 3D printers. It’s quite a tall system, which obviously requires an open top – meaning it’s likely this is not applicable for systems with full enclosures. But I am certain they will explain more when they launch the product.

Alas, the Ceramic 3D Printing KIT is not quite available for purchase yet. They do plan to launch a Kickstarter sometime in January, and expect to post a price of €450 (USD$530), with shipping for the following April.

Via StoneFlower