![3D printing electrically conductive material [Source: Wiley]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb092f651037.jpg)

I’m reading a paper describing a new method for 3D printing supercapacitors.

Fabbaloo readers will no doubt be familiar with the 3D printing of plastic, metal or even food, but electrical objects are a rarity these days in 3D printing. That’s because the conductive materials that one might use for such work are simply not viable yet for practical applications.

Now, researchers from the University of Manchester seem to have developed a step towards a practical ability to 3D print supercapacitors.

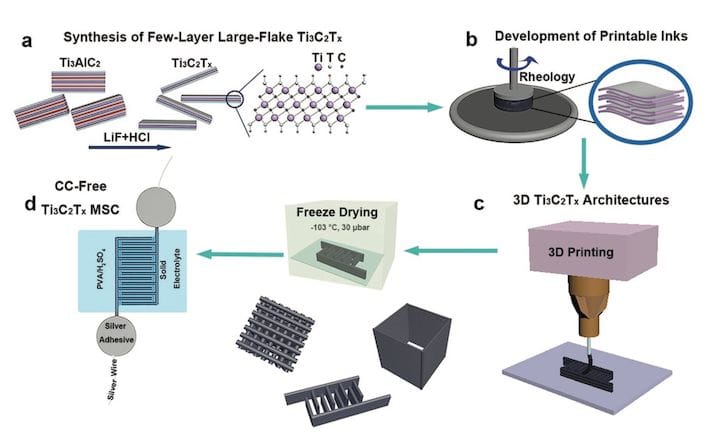

Their approach is to use a “2D” liquid material infused with microscopic flakes of Ti3C2Tx. This allowed for a solution that had the rare combination of being sufficiently viscous to properly 3D print and at the same time providing a useful electrical capacity.

They explain:

“Herein, aqueous inks composed of atomically thin (1–3 nm) 2D Ti3C2Tx with large lateral size of about 8 μm possessing ideal viscoelastic properties are formulated for extrusion-based 3D printing of freestanding, high specific surface area architectures to determine the viability of manufacturing energy storage devices.

The 3D-printed device achieves a high areal capacitance of 2.1 F cm−2 at 1.7 mA cm−2 and a gravimetric capacitance of 242.5 F g−1 at 0.2 A g−1 with a retention of above 90% capacitance for 10 000 cycles. It also exhibits a high energy density of 0.0244 mWh cm−2 and a power density of 0.64 mW cm−2 at 4.3 mA cm−2.”

And:

“The unique rheological properties achieved by the 2D MXene inks combined with the sustainability of the approach can serve as a base to explore other applications requiring controlled 3D architectures and the methodology could be expanded to incorporate other functional and structural materials into MXene-based 3D printable inks.

We anticipate that the capability to print customized MXene architectures in three dimensions, which has been demonstrated in this work, will open new opportunities to realize high-performance multiscale and multidimensional devices, as required for many different energy, catalysis, and transportation applications.”

This is quite intriguing, as this research may lead to an ability to 3D print supercapacitors in arbitrary shapes. Currently, batters and supercapacitors are pre-made in specific standard shapes, and products using them must “build around the shape”. This creates design constraints that are sometimes unwelcome.

Embedded 3D Printed Supercapacitors

By freeing the supercapacitor’s geometry from the constraints, it might be possible to achieve far more optimized overall product designs. This would be of specific interest to small, handheld devices that require power.

Often such devices have considerable empty space within them that is unused yet contributes to the device’s dimensions. Imagine if this empty space could instead be converted to electrical storage.

Devices might be smaller, or, if design goals are different, the power capacity could be increased.

Via Wiley

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.