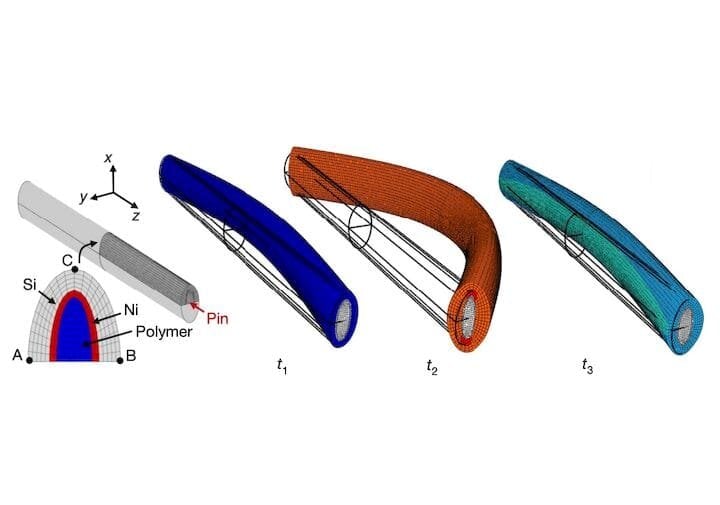

![Example of architected material that bends when electrical current is applied [Source: Nature]](https://fabbaloo.com/wp-content/uploads/2020/05/architected-material_img_5eb09065d85ef.jpg) Example of architected material that bends when electrical current is applied [Source: Nature]

Example of architected material that bends when electrical current is applied [Source: Nature]

Researchers at Georgia Tech, CalTech and ETH Zurich jointly developed a way to “architect” certain types of materials, and these could potentially be used in conjunction with 3D printing approaches.

There have been several developments in reconfigurable materials previously, but most require a constant stimulus to maintain a change in material shape. The new research seems to have discovered a way to change shape without having to re-apply the external stimulation.

Shape-Changing 3D Prints

The idea is to create carefully designed structures that perform a function when distorted. This is accomplished by ingeniously designing a lattice structure with purposely-embedded defects in the material.

These defects can be exploited by careful manipulation of external stimuli, in this case electricity. An application of electricity will cause these shapes to bend in predictable ways.

How is this done? Apparently the researchers used a two-photon 3D printer to produce a microscopic lattice structure from polymers. Then they sputtered a delicate combination of metal and silicon on top using a vapor deposition technique.

An application of current then caused the microstructures to buckle in expected directions. The researchers found that they could control the degree of buckling by moderating the electrical current applied. After the current was removed, the buckling effect was retained.

Shape Changing Products?

This is obviously very early research and far from commercialization at this point, but it is quite an intriguing approach. It’s also doable only with an application of 3D printing, as that is a key step in their process.

Looking forward, it might be possible to 3D print larger structures using this approach that could perform useful functions. I imagine sensors, valves and other components could be produced eventually.

These components could become part of future “smart objects” where the functions are directly 3D printed into the item all at once, if one were to combine several different types of 3D printing technology into a single machine.

Via Nature