A group of researchers at Vanderbilt University have developed an approach for 3D printing thermite to perform part joining.

Thermite is a volatile compound that burns at extreme temperatures if ignited. Typical heat achieved can exceed 2200C, hot enough to melt or burn many common substances. The thermite mix used by the researchers was a combination of iron oxide, aluminum powder and calcium sulfate hemihydrate.

Shaped Charges

The idea here takes an explosive cue from industry and military, where “shaped charges” are often used. The idea of a shaped charge is to control, to some degree, the forces generated by the explosion. This is done by altering the geometry of the explosive material so that it burns rapidly in a predictable and beneficial way.

A similar idea is taking place here: the researchers had the idea of creating a shaped thermite object that would self-control its own burning sequence. To make such an object, they turned to 3D printing technology.

This is done by leveraging the property of thermite to burn along an edge: for example, if you had a long rectangle of thermite and ignited it at one end, a burn zone would travel along the path of the rectangle until all was consumed. The burn zone would have a measurable “velocity”. The researchers report their velocity was near 3.2mm per second, so you can get an idea of how fast this process proceeds.

That simple example can be made much more complex by altering the geometry of the thermite object. In this way the researchers were able to create thermite objects with controllable burn properties.

3D Printing Thermite

You cannot simply order 3D printable thermite, as that would be a rather dangerous material to sell and use. Instead, the researchers devised a mix of thermite and gypsum powder as binder. This was 3D printable and could be cured to a solid form after printing using warm air.

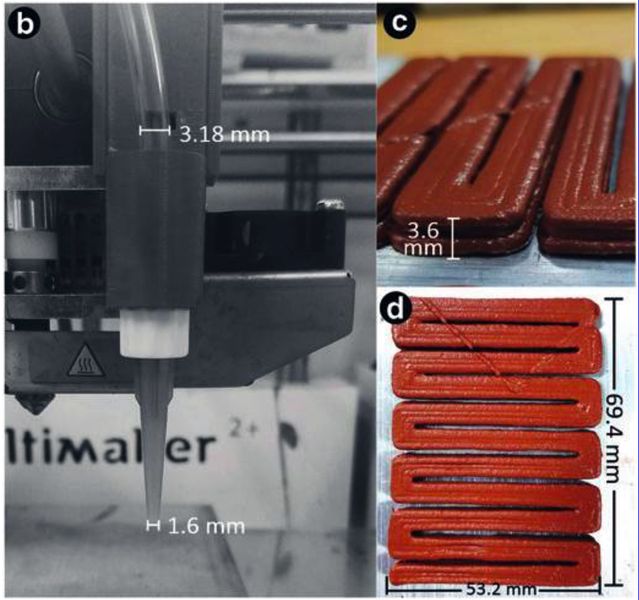

For printing, the researchers used a standard Ultimaker 3D printer, but one with a syringe extrusion system. In this case they used the Discov3ry paste extruder made by Structur3D, which we’ve looked at in the past. This is a standard paste extrusion system that’s commonly used as an add-on by experimenters.

While the researchers here used a rather coarse extrusion system, there seem to be few barriers to 3D printing thermite objects at far smaller scales and with more complex geometries. Internal voids, for example, could be used to generate delays in burning sequences. It’s somewhat reminiscent of designing an electrical circuit, albeit in slow motion.

Using 3D Printed Thermite

The researchers designed several architectures to test the propagation of ignition, and were able to measure several different speeds depending on the geometry. This should be the beginning of a much more complex domain in which thermite designs are applied to real-life situations.

There are several possible applications for this technology.

One might be to 3D print pre-made thermite “patches” that can be used to precisely weld a specific joint. Imagine a “kit” to be assembled in the field, where you place the parts together and slap on the thermite patches that weld the joints together. This would avoid the need to transport heavy welding gear into the field site.

Another application could be underwater welding, as thermite burns well under water because it brings along its own oxygen in the form of iron oxide. A similar 3D printed thermite patch could be used to create joints by simple application rather than having an expensive robot or diver do the job.

It sounds quite interesting, but if you’re considering looking into this yourself, be aware that thermite can be a very dangerous material.

Via Liebert