What’s your print time? If you’re using a resin 3D printer, it’s longer than you think.

Speed has long been the bugaboo of 3D printing, simply because virtually all 3D printing processes are quite slow to produce objects. The only exception is the up and coming volumetric 3D printing systems, but that’s another story.

3D printer manufacturers have dealt with this issue in two ways: speeding up the printing process and optimizing the entire production process.

To speed up FFF 3D printers, device manufacturers increased component quality, used faster controller boards, lengthened hot zones and other techniques to blast out softened thermoplastic as rapidly as possible.

To speed up resin 3D printers, many device manufacturers have turned to monochrome LCD panels, which enable the transmission of much more energy per pixel than the usual RGB color-filtered LCD panels originally used. This cuts the per-layer time down to only a second or two in some cases. Other manufacturers have reduced or eliminated the “peel and reposition” steps by developing continuous 3D printing processes, like Carbon’s DLS.

To speed up metal 3D printers, device manufacturers have installed multiple lasers into their equipment to enable layer melting to operate in parallel, increasing overall print speed.

These are all terrific, but when I’m using a resin 3D printer, speeding up the layer time is the least of my concerns. Let’s take a look at my workflow, yours may be somewhat different:

- (0:15-1:00h) Set up the print job usually with tedious manual support configurations

- (0:01-0:05h) Transfer print job to printer and start job

- (1:00-5:00h) Wait for printing to complete

- (0:05-0:05h) Find and wear PPE; set up workspace for print removal

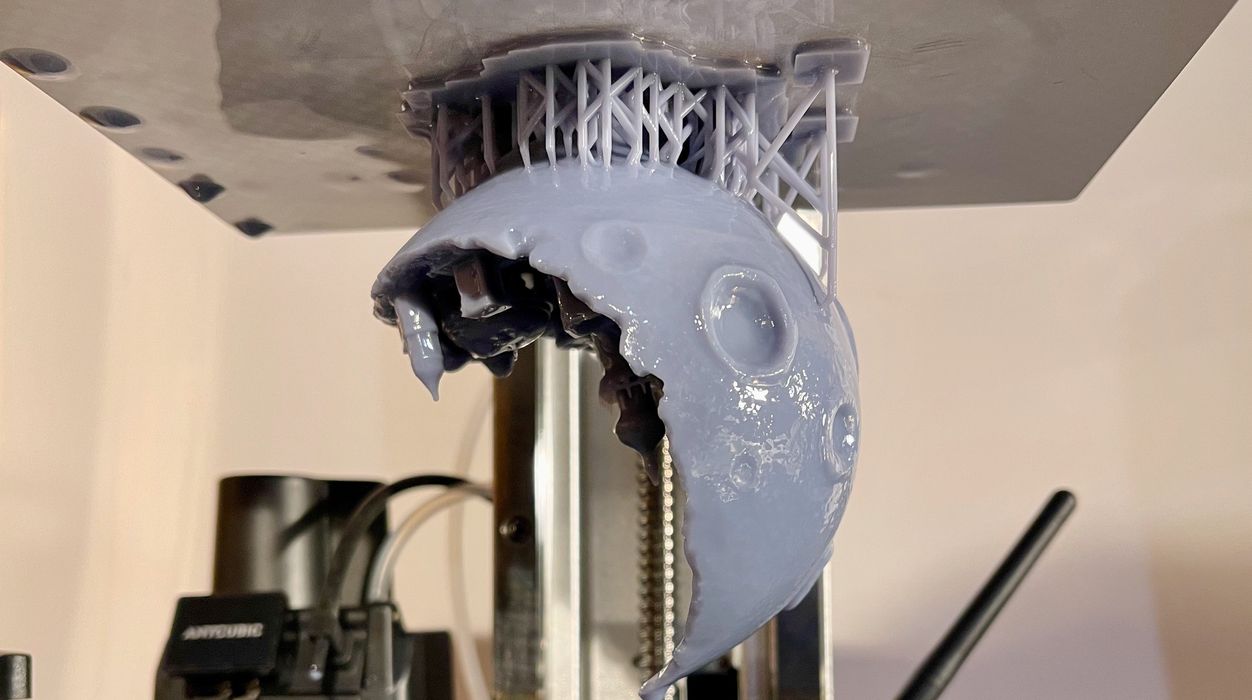

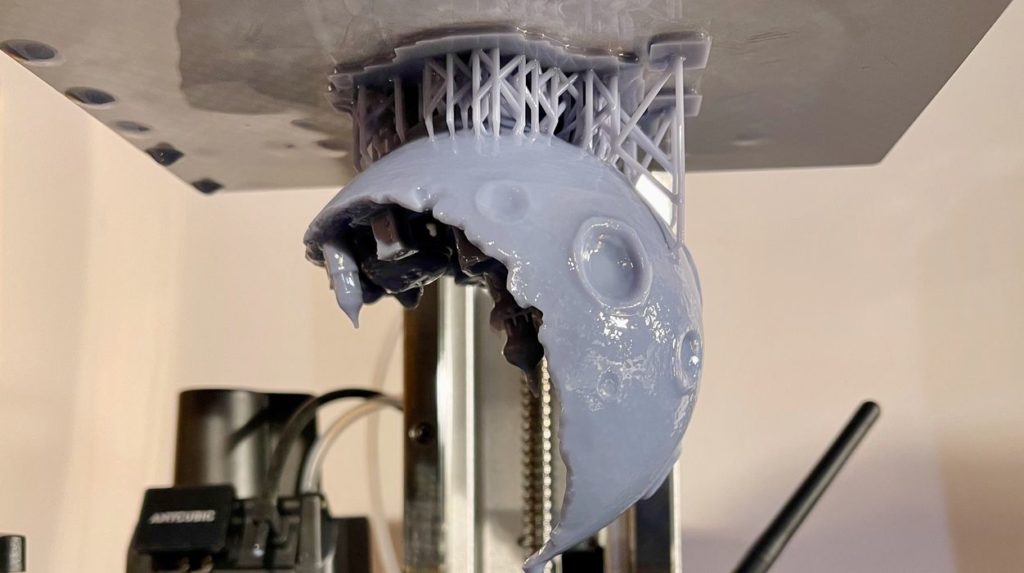

- (0:05-0:15h) Extract print from plate without making too much mess

- (0:05-0:30h) Basic “dirty” wash of print

- (0:05-0:10h) Final “clean” wash of print

- (2:00-4:00h) Lengthy soak to remove all odors

- (0:30-1:00h) Drying print before UV curing

- (0:05-0:30h) Manual removal of support structures and part cleanup

- (0:05-0:15h) Clean up the workspace and tools

- (0:05-0:20h) UV curing

Again, this is my experience, your workflow might be a little different, and particular models could change things significantly. But the important thing to note is that while the “printing” step is usually the longest, there are a ton of other steps that must also be done, far more steps than are done with FFF 3D prints.

In my loose estimate above, it would seem that from start to finish and having the completed print in your hand, my minimum time is going to be at least four hours, even for the simplest possible print. In more typical cases I might take more than twelve hours.

The actual print time is not the majority of the work effort here. It’s really all the other things you must do. Once you hit “print”, you are committing to performing all those other steps, or some variation of them. This also doesn’t include periodic activities, like cleaning your wash fluids, or replacing resin bottles.

Here’s the point: resin 3D printer manufacturers have spent considerable effort to speed up the printing process, but far less effort in simplifying some of the remaining steps.

Sometimes I see developments in that area. One, for example, is that Anycubic’s Wash & Cure machine has a basket that perfectly fits the build plate of one of their machines. You can simply drop the whole plate in and wash it too, shortening the workflow and keeping the plate clean. But aside from that there seems to be little interest in the “other” part of the work required for resin 3D printing.

If a resin 3D printer manufacturer were to attack that part of the workflow, we’d likely see redesigns in the 3D printer and wash station gear. This has been done in some industrial 3D printers, where companies like Additive Industries recognize the several steps required to perform metal 3D printing and built a machine with multiple stages to handle each, greatly simplifying the workflow.

Could the resin 3D printer manufacturers turn their attention to this aspect of operations? The machines are already plenty fast, but we need to speed up the rest of the work. That could lead to expanded sales to those concerned about all the effort required for resin 3D printing.

Resin 3D printing can produce prints of truly outstanding quality, but honestly, it’s really a pain to do all the work.